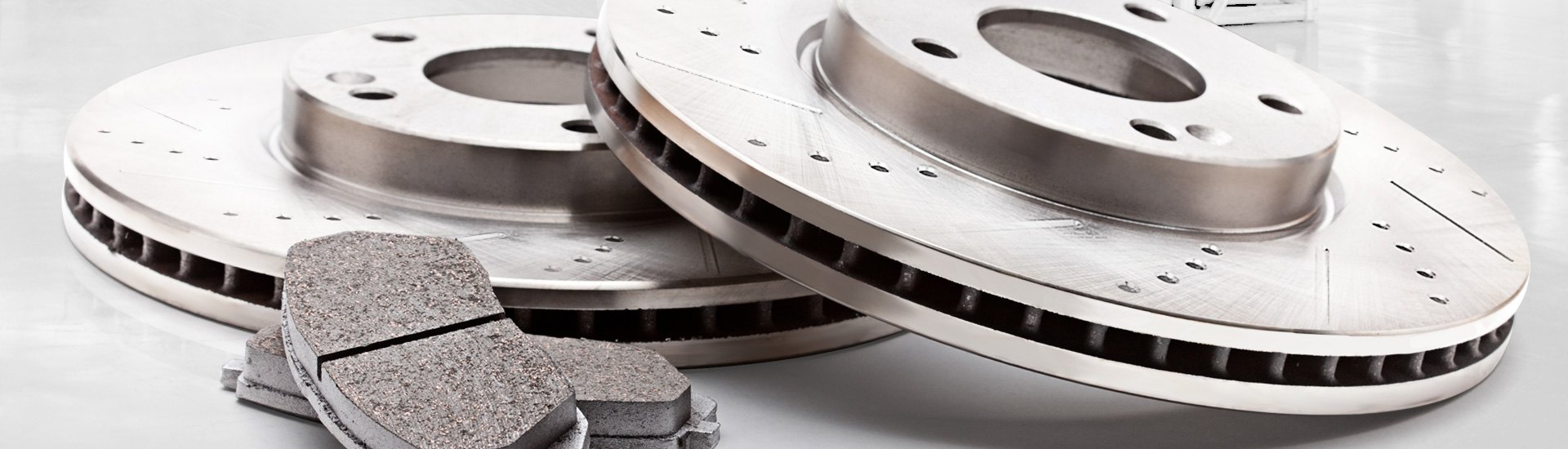

Whether you're looking to replace worn brake pads and rotors or delving into more detailed brake repairs or upgrades that involve new calipers, proportioning valves, master cylinders, vacuum boosters, and more, you will come across a lot of different terminology when it comes to brake components.

Depending on your knowledge and experience, a lot of these terms may be elementary. However, because many of them use similar words but represent completely different things, we've created this glossary to help you understand exactly what you need, and what you don't.

Because no one is born knowing all these expressions, taking a quick look through this section is sure to be helpful. And when you do decide on what you need, CARiD offers a huge selection of OEM style brake parts and Anti-lock Brake System parts that match OEM factory specifications - for vehicles old and new.

We also have performance brake components that will effectively increase your car or truck's stopping power, reduce brake fade, and even cut unsprung weight from your suspension. If you see a highlighted term or word, clicking on it will take you directly to the applicable product page on our website where you'll find items for sale.

ABS, Or Anti-lock Brakes

An automatic system that applies brake pressure, then releases, then applies in a rapid, pulsating fashion repeatedly in order to ensure braking effectiveness on slippery surfaces that would otherwise lead to a skid. Sensors at each wheel measure wheel speed, and can detect if wheels lock up during braking. Should this happen, the ABS system is activated.

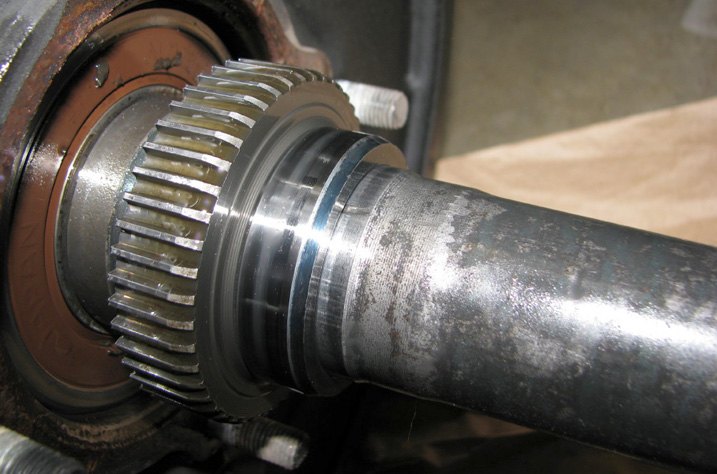

ABS Ring

An ABS ring is a notched ring attached to a wheel hub or behind a brake rotor that is read by an ABS wheel speed sensor to determine the speed of an individual wheel.

ABS Wheel Speed Sensor

A sensor mounted behind a brake rotor that computes the speed of a wheel by reading the notches on a ring attached to the wheel hub or behind a brake rotor. Individual ABS wheel speed sensors at each of the vehicle's 4 wheels send their information to an anti-lock brake control module. If this module sees a significant difference in the speed of one or more wheels, the ABS system will begin pulsating the brakes to prevent a skid. Information obtained by these wheel speed sensors can also be used in traction control systems to determine if drive wheels are spinning on snow or ice.

Electronic stability control systems can also use these sensors to apply brake power at one or more wheels to keep the vehicle tracking straight in emergency situations. You can see an ABS wheel speed sensor sample at CARiD.

Accumulator

A specially designed reservoir that serves to store pressure needed for antilock brake system operation. A nitrogen-charged chamber is sealed off by a rubber diaphragm, and the nitrogen in this chamber becomes pressurized as brake fluid is pumped into the accumulator by the ABS pump.

Anti-Rattle Springs and Clips

Spring-loaded metal hardware pieces which mount to disc brake calipers or pads. Anti-rattle clips provide tension necessary to prevent pad looseness that creates vibrations and rattling noises.

Backing Plate

On drum brake vehicles, a backing plate is a flat metal plate inside the brake drum on which the brake shoes, wheel cylinders, and other brake parts are mounted. See also "dust shields" for disc brake vehicles. To view backing plates we offer: click here.

'Bell Mouth'

A condition on drum brakes where the drum expands outward at its open end. This happens because the metal thickness of the drum has become thinner due to wear, and it's lost structural integrity. Because the brake shoes, which are still flat across, cannot make proper contact to create braking friction, the drum needs to be replaced.

Bench Bleeding

The process of bleeding air out of a master cylinder before installing it in place on the vehicle. See also "brake system bleeding".

Bleeder Hose

A section of plastic hose or rubber tubing used to bleed brake fluid out of the brake system. One end of the tube mounts over the bleeder screw on the caliper housing. When the screw is loosened, brake fluid flows out into a container where the other end of the hose is placed. These are often found in brake bleeder kits.

Bleeder Screw

A screw valve designed with a hollow center to allow fluid to be bled through it when the screw itself is loosened with a wrench. In brake systems, bleeder screws are found on disc brake calipers and drum brake wheel cylinders as well as on some master cylinders and ABS modulators.

Bonded Brake Linings

When brake linings are attached to disc brake pads or shoes with a bonding adhesive instead of rivets. In the above picture, a bonded brake shoe is shown on top, and a riveted shoe is shown on the bottom.

Brake Cleaner

A strong chemical solvent (usually packaged in an aerosol spray can) that removes grime, caked-on grease, and brake dust on contact. While this type of cleaner is effective on almost any metal automotive part, the name "brake cleaner" was applied because it's most often used on brake components. Solvents designed for cleaning brakes typically do not contain petroleum-based solvents or degreasers because those leave a residue which can degrade rubber parts. To view brake parts cleaners, click here.

Brake Fluid

Specially designed hydraulic fluid for automotive brake systems. As the brake pedal is applied, a piston in the master cylinder pushes brake fluid out of the reservoir through the brake lines. Once it reaches the wheels, the fluid pressure compresses the pistons in a disc brake caliper or drum brake wheel cylinder. As a result, brakes are applied. Brake fluid is currently available in three grades: DOT 3, 4, and 5. See those related definitions. To view brake fluids we offer: click here.

Brake Fluid Reservoir

A container, usually made of clear plastic, which is joined to a master cylinder assembly to hold extra fluid needed for the brake system. The reservoir has a fill hole, and a sensor connected to measure when fluid level becomes low. Note that some older master cylinder designs are manufactured with an integral reservoir. To view brake fluid reservoirs we offer, click here.

Brake Fluid Tester

A specially designed tool that senses and reports the percentage of moisture in brake fluid. To view brake fluid testers we offer, click here.

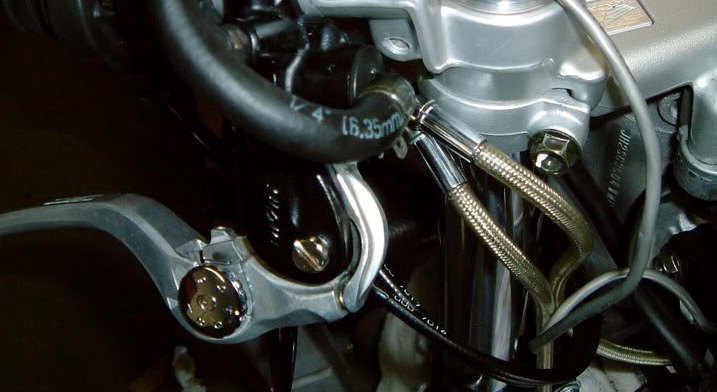

Brake Hose

Tubes made of rubber or flexible braided steel which bridge the gap between steel brake lines from the master cylinder and the brakes at the wheels (either disc brake calipers or drum brake wheel cylinders). Flexibility is needed to allow for steering angle changes and up-and-down suspension travel. To view OEM-style brake hoses we offer: click here. For performance-oriented brake hoses we offer: click here.

Brake Lines

Specially designed non-flexible steel tubing (usually stainless) that delivers brake fluid under high pressure from the master cylinder to the flexible brake hose sections at each wheel. Flared fittings at the ends of brake lines are either "double flared" or "ISO flared" (International Standards Organization) in design, and are not interchangeable.

Brake Lubricant

Synthetic grease or silicone specially designed to handle the high temperatures to which brake components are subject. It's used to lubricate disc brake guide pins as well as drum brake self-adjusters and star wheels. Applied to the back of disc brake pads or drum brake shoes, anti-seize lubricant also provides cushioning to quell high-frequency vibrations that cause squealing noise.

Brake Pedal Position Switch

A sensor that determines if the brake pedal is being depressed. Some brake switches measure how far the pedal has actually travelled, while others do not. This information is used to turn on the vehicle's brake lights, and is used by the vehicle's main computer to regulate ABS, traction control, and other systems related to brake activity. To view brake pedal position switches we offer, click here.

Brake Spoon

Specially shaped tool designed to be inserted in the opening found on the back of backing plates on drum brakes. When inserted, the spoon can be used to adjust clearance between brake shoes and the drum by turning a star wheel adjuster gear.

Brake System Bleeding

The process of purging old brake fluid out of the system. This is necessary after brake system repairs when air has entered the lines to avoid a spongy-feeling brake pedal and reduced stopping power. Because brake fluid normally becomes contaminated over time with moisture and other unwanted toxins, many vehicle manufacturers specify a complete bleeding of the brake system every 2-3 years, including the addition of fresh brake fluid. To view brake bleeders we offer: click here.

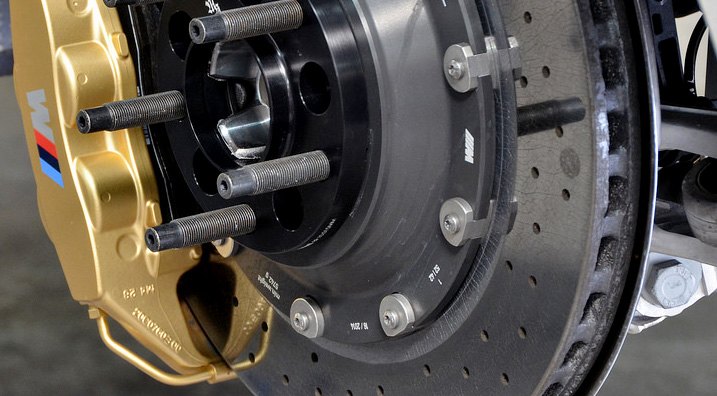

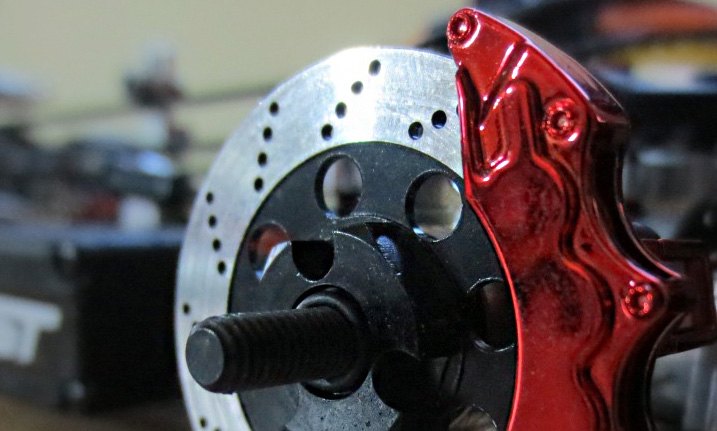

Caliper

A brake caliper, found only on disc brakes, houses pistons which use the force of hydraulic brake fluid to squeeze brake pads against the rotor – creating stopping force. Calipers can contain a varying number of pistons, and feature a "fixed" or "floating" mount design (see separate definitions). To view OEM-style calipers and related parts we offer: click here. For performance-oriented calipers we offer: click here.

Caliper Bolt

A removable bolt (or "guide pin") that allows brake pads to slide back and forth when brake pressure is applied and released. Caliper bolts are temporarily removed when brake pads are replaced, during which time they must be cleaned and re-lubricated with anti-seize lubricant. We’ve got a great selection of caliper bolts, guide pins, and other items in our brake hardware section.

Caliper Mounting Bracket

Floating brake calipers are secured in in mounting brackets, which bolt directly to the vehicle's spindle or suspension. To see caliper mounting brackets and mounting plates we offer, click here.

Ceramic Brakes (a.k.a. 'Carbon Ceramic')

These are brake pads and rotors made from special porcelain compound blends instead of traditional materials. Ceramic brake components resist heat buildup far better, offer greater stopping ability, and resist corrosion. A favorite of racers, their availability as optional factory equipment on high-end performance models has steadily grown. Availability of aftermarket ceramic brakes is lower than any other kind because their high cost makes them a specialized item. View performance-oriented ceramic brake pads and ceramic brake kits (with pads, rotors, and more) that we offer.

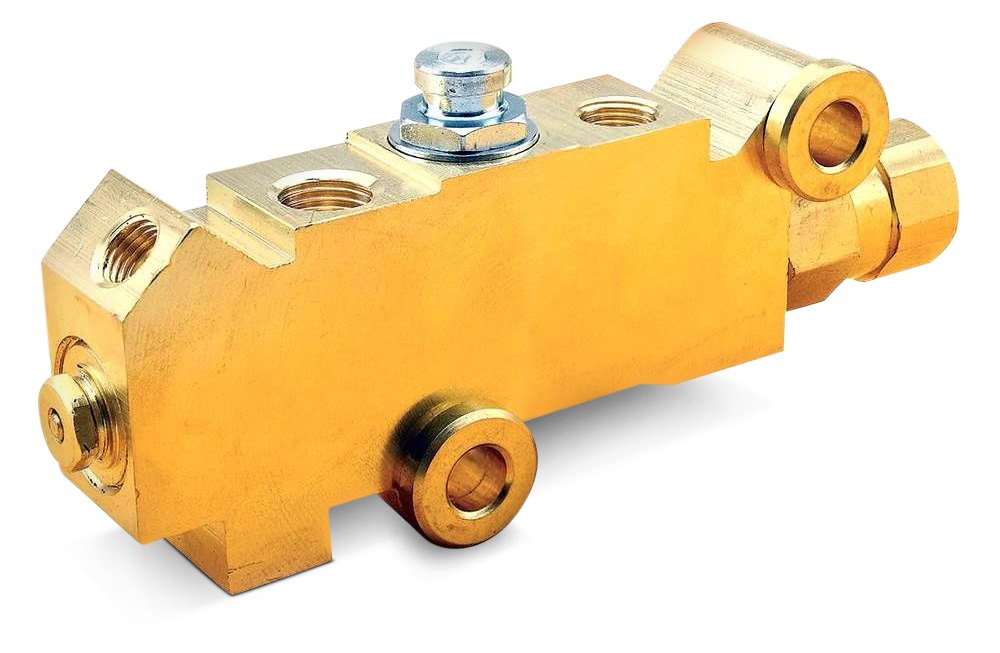

Combination Valve

A brake valve that combines two or more brake fluid valves (proportioning valve, pressure differential valve and/or metering valve) into a single housing.

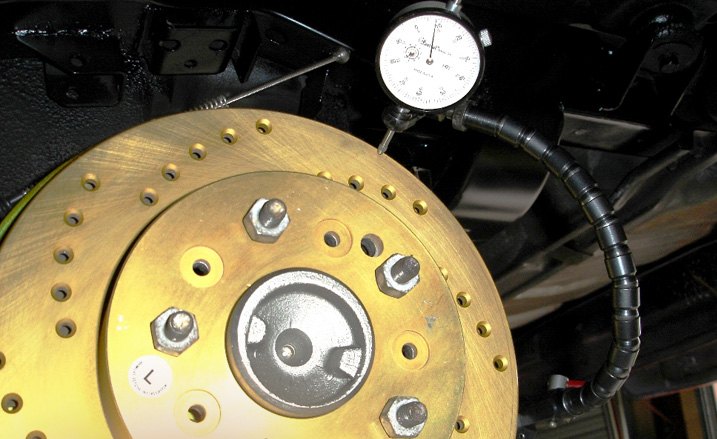

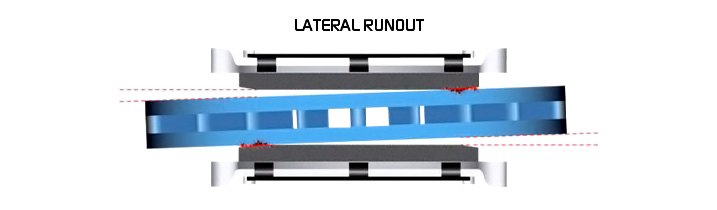

Dial Indicator

A gauge with a finely-tuned needle that measures any warpage (runout) or unevenness on the face of a brake rotor, as the rotor is spun around. The amount of runout detected can then be compared to vehicle manufacturer specifications to determine if the rotor should be replaced, or resurfaced. This gauge can also be used to detect wheel bearing play. For dial indicators we offer, click here.

Dimpled Brake Rotors

Rotor surfaces with holes that have been partially drilled through are also known as 'dimpled'. While they don't pose the same risk of cracking as fully-drilled rotors do, dimpled rotors sweep away less heat and debris.

Disc - See Rotor

DOT 3 Brake Fluid (DOT = Department of Transportation)

Most commonly specified by auto manufacturers, DOT 3 brake fluid meets U.S. Department of Transportation specifications for glycol-based fluids with a wet boiling point (lowest allowable after it's been in use) of 284 degrees Fahrenheit and a dry boiling point of 401 degrees F. Because DOT 3 is glycol-based, it absorbs moisture over time.

DOT 4 Brake Fluid

Like DOT 3 fluid, DOT 4 is also glycol-based. It's suited for heavier-duty use and higher brake temperatures thanks to a higher wet boiling point of 311 degrees Fahrenheit and a dry boiling point of 446 degrees. DOT 4 brake fluid is ideal for high-performance vehicles that see aggressive use on the street and/or racetrack. Because DOT 4 fluid is glycol-based, it absorbs moisture over time.

DOT 5 Brake Fluid

This is a silicone-based fluid that has a boiling point of at least 500 degrees Fahrenheit. Because it does not absorb moisture like DOT 3 & 4 fluids, DOT 5 fluid doesn't need to be changed as a matter of routine maintenance. And like synthetic motor oil, DOT 5 fluid can cost three to five times as much. DOT 5 is NOT recommended for ABS systems because it can aerate when cycled through small orifices. Additionally, it will not mix with DOT 3 or DOT 4 brake fluid.

DOT 5.1 Brake Fluid

This is a glycol-based, non-silicone version of DOT5. Both have the same boiling points, but DOT 5.1 embodies all the other physical characteristics of DOT 3 and 4.

Drilled Brake Rotors

Drilled disc brake rotors feature holes that reach all the way through to the other side - a layout that ensures maximum dissipation of heat and debris. Some drilled rotors may also feature slots (see slotted rotors) in their faces as well. Because they pass off heat faster, drilled rotors offer an advantage over slotted ones during high performance driving and racing.

Since the drilled holes take mass out of the rotors, cracks may occur between the perforations when used on a vehicle that takes on a greater weight load due to hauling of heavy cargo or sustained towing. Vehicles with built-up engines, turbos, or superchargers can also have a damaging effect on drilled rotors, especially when abused by either stunt driving or drifting.

Drum

The ring-shaped outer housing which rotates with a vehicle's wheel and fits over all the internal components of a drum brake setup. The inside of the drum provides the friction surface for drum brake shoes to press against. While most drums are made from iron, some feature lightweight aluminum construction with a cast iron liner. To view OEM-style brake drums we offer: click here.

Drum Brakes

A brake setup that uses curved brake shoes that move outward and exert stopping pressure against the inner surface of a brake drum. Compared to more modern disc brake setups, drum brakes are lower in cost to produce. Because they do not dissipate heat as well, they are more subject to overheating and reduced performance from brake fade. Drum brakes are found on older vehicles and on the rear of some low-cost trim versions of newer passenger cars and trucks.

Drum Brake Linings

These are essentially curved brake pads designed for drum brake systems. The linings are attached to metal brake shoes which provide structural support, similar to the way backing plates on disc brake pads do. In some cases, brake linings are available separately. However, in most cases, linings are sold together with brake shoes.

Dual Master Cylinder

A master cylinder that's divided into two separate hydraulic circuits - each with a separate fluid reservoir and piston. Should the brake system develop a leak anywhere, only one of the two circuits will be affected - leaving some brake power to stop the car. To view master cylinders we offer: click here.

Dust Boot

A rubber seal (or boot) on a disc brake caliper which prevents moisture and outside contaminants from entering the cylinder area where the piston compresses brake fluid. An example of dust boots as part of a repair kit can be found here.

Dust Shield

For vehicles with disc brakes, a dust shield is a thin sheet of metal permanently bolted in place behind the rotor. This protects the rotor, caliper, pads, and other components from rocks, grit, and other debris found on the road. See also "backing plates" for a link to applicable products.

Electronic E-brake

A more modern setup on vehicles with rear disc brakes. Instead of pulling a manual lever that's connected to a emergency brake shoes via a cable, electronic setups use electric servo motors to apply the e-brakes. Vehicle electronics can also be used to automatically activate the e-brake whenever the vehicle is parked, or when sensors detect the vehicle is stopped on a hill with the brake pedal applied.

Emergency Brake (a.k.a. 'E-Brake', a.k.a. 'Parking Brake')

A mechanical brake used on vehicles without a "park" function in the transmission, such as on manual transmission vehicles. Also a mechanical back-up system that will activate rear brakes should all hydraulic operation somehow fail. Manually operated e-brakes use a cable connected to a pull lever or a foot pedal, while electronic e-brakes contain a separate set of servo motors by the wheels. In a rear disc brake setup, small drum-type emergency brake shoes press against the inside of the center hub area ("hat") of the rotor. In a drum brake setup, the cable activates the regular brake shoes. To view OEM-style emergency brake components we offer, click here. For performance-oriented emergency brake kits, click here.

Equalizer Yoke

A Y-shaped mechanism that equally splits pressure from the emergency brake cable to the left- and right-side rear wheels. For equalizer yokes we sell, click here.

Fade

When brake pad (or shoe) grip diminishes because brake components have been overheated. This can occur from continuous high-speed brake applications during aggressive driving or racing, or when brakes become overloaded due to excessive cargo weight or trailer towing. Overheated brake fluid can also become aerated, adding to the effect. When brake fade occurs, stopping to let the brakes cool down will restore braking ability.

Fixed Brake Caliper

Fixed disc brake calipers remain stationary because they’re fixed in place over the center of the brake rotor. In contrast, a floating caliper housing will slide from side to side so that a single piston can apply pressure to pads on both sides.

Floating Brake Caliper

A type of disc brake caliper where the housing is designed to slide on guide pins from side to side over the brake rotor. This allows a single piston to squeeze brake pads on both sides of the rotor. When the piston moves outward, the inboard pad contacts the rotor first, causing the caliper to slide over until the outer pad makes contact with the rotor. When the brakes are released, the floating caliper self-centers itself over the middle of the rotor.

Guide Pin

See “caliper bolt”.

Hold Down Springs

In a drum brake system, these springs with hooks on the end secure the brake shoes to the backing plate. Normally, these are replaced with brake shoes, and are frequently included with a brake hardware kit. To see our selection of hold-down springs, click here.

Hydro-Boost

A less common power brake setup which uses hydraulic pressure from the power steering pump to provide brake assist, instead of vacuum pressure.

Hygroscopic

An object or fluid is hygroscopic when it naturally absorbs and retains water moisture. Glycol-based DOT 3 and DOT 4 brake fluid are hygroscopic, but silicone-based DOT 5 fluid is not. Moisture in brake lines can cause mushy brake pedal feel, and it can corrode metal components from the inside out.

Loaded Brake Caliper

A disc brake caliper that includes a set of pads and hardware. Normally, calipers and brake pads are sold separately. A loaded caliper allows manufacturers to match calipers and pads together which are designed for a similar type of performance such as racing or towing.

Manual Bleeding

Instead of using a pressure pump attached to the brake fluid reservoir to force old brake fluid out of the lines, the brake pedal is depressed manually. Manual bleeding is usually a two-person job. Bleeder screws on the caliper are opened one at a time, starting at the wheel farthest from the master cylinder.

After the pedal is fully depressed and brake fluid has flowed out through a tube that's submerged in a container of old fluid, the bleeder screw is closed so that air does not get sucked back into the lines when the pedal rises back up. As this process is repeated at all 4 wheels, fresh brake fluid is added to the reservoir until new fluid is coming out of the lines. See also "brake system bleeding".

Master Cylinder

Brake component which uses small pistons within its body to compress brake fluid. A rod leading from the brake pedal pushes pistons which compress the fluid, creating hydraulic pressure in the brake lines that serves to apply brakes at the wheels. The vehicle's reservoir for brake fluid is mounted on top of the master cylinder, and this is where fluid is added. To view OEM-style master cylinders & reservoirs we offer: click here.

Metering Valve

Valve which reduces fluid pressure sent to the front brakes to ensure that rear brakes will apply evenly, because rear brakes are generally smaller and take more force to apply. A metering valve may be a separate component, or it may be integrated into a larger combination valve.

Modulator Assembly

A single control unit for ABS braking systems that contains solenoids, valves, fluid pump, and accumulator. ABS modulators are part of master cylinder assemblies in "integral" ABS systems, but separate in "non-integral" ABS systems.

Organic Brake Pads (a.k.a. 'Non Asbestos Organic' or 'NAO')

A type of brake pad or shoe lining material that's not constructed with cancer-causing asbestos fibers. Depending on construction, it may or may not have some degree of metallic makeup. You'll find organic pads in both our OEM-style replacement sections and performance sections.

Pad

In disc brake systems, brake pads are located inside caliper assemblies. As the brake pedal is pressed, hydraulic pressure in the lines builds up and forces the pads to apply clamping force onto a spinning rotor, effectively slowing the vehicle. Click here to view our OEM style replacement disc brake pads, and here to view high-performance pads we offer.

Pad Wear Sensor

An electronic sensor that determines when brake pads have reached a pre-determined minimum thickness and should be replaced. The most common type of wear sensor is separate from the brake pad, and clips on to it. On other applications, the sensor is embedded into the brake pad itself and cannot be replaced independently. When enough pad material wears away, the metal contact prong makes contact with the rotor - effectively grounding the sensor and triggering a warning light on the dash. See brake pad wear sensors we offer here.

Parking Brake - See Emergency Brake

Piston

A piston inside a disc brake caliper or wheel cylinder that moves from hydraulic pressure, forcing brake pads or shoes into contact with rotors or drums. Fixed calipers have an even number of pistons on opposing sides of the caliper. Floating calipers have one or more pistons only on one side of the caliper. Wheel cylinder pistons on drum brakes are usually steel but caliper pistons may be steel, aluminum, or phenolic. Phenolic pistons are made of plastic phenolic resin and offer benefits such as lighter weight, resistance to corrosion, and the ability to absorb heat better than metal pistons. We offer an array of replacement caliper pistons – click here to view.

Piston Reset Tool

Some pistons on disc brake calipers need to be rotated as they are compressed inward to clear new brake pads that are being installed. A piston reset tool features multiple sides with pegs spaced a variety of distances apart. These pegs fit into holes in the outer lip of the caliper piston. Click here to see some of the caliper rewind tools we offer, along with caliper spreaders.

Pressure Bleeding

Process for purging old brake fluid and air out of the system by using a canister with a built-in hand pump. After connecting the pressure bleeder to the brake fluid reservoir, pressure is pumped up by hand. As brake bleeder screws are opened, new fluid from the pressure tank is forced into the lines, and old fluid is forced out. Because pressure is created, and held, by the pressure bleeder unit, one person is able to do this job, and a second person is not required to manually step on the brake pedal. See also "brake system bleeding".

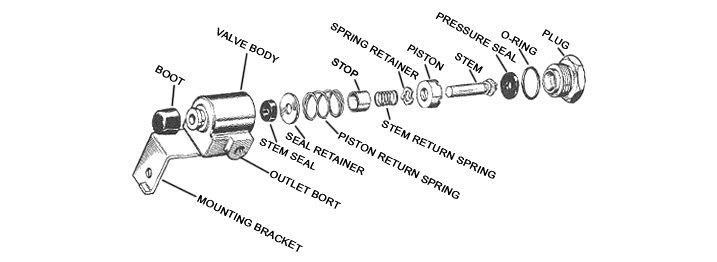

Pressure Differential Valve

A safety valve that monitors whether fluid pressure is equal in both separate brake system circuits. The check valve self centers itself under normal conditions, and a loss of pressure on either side will cause it to move one way or the other - triggering a warning light. The pressure differential valve may be integrated into a larger proportioning valve.

Proportioning Valve

To prevent rear wheel lockup, proportioning valves reduce brake fluid pressure to the rear to compensate for forward weight transfer that occurs after brakes are initially applied. A "load-sensing" proportioning valve uses a lever between the rear suspension and chassis to adjust the amount of brake force based on how weighed down a vehicle is. Rear brake force is increased because the lower ride height moves the lever and opens the valve.

Pull

When a vehicle that otherwise tracks straight begins to pull to one side as brake pressure increases. This condition may be caused by a frozen wheel cylinder or caliper that isn't applying proper pressure, or uneven hydraulic pressure due to faulty check valves.

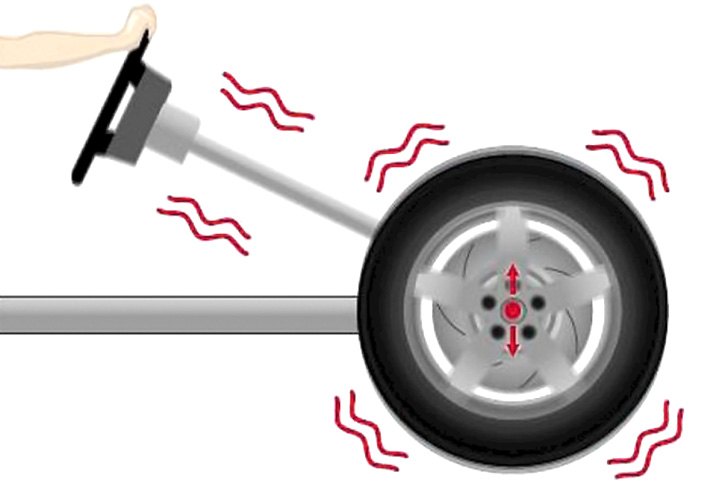

Pulsation

When a brake rotor that's become hot-spotted or warped like an old record transfers the resulting vibration to the frame of your vehicle as it rotates. Warped front rotors will also tend to cause pulsation that can be felt in the brake pedal and steering wheel also. Resurfacing the old rotor or replacing it with a new one will fix the problem.

Quick Take-Up Master Cylinder

To reduce minor brake pad drag inherent in normal disc brake systems, a quick take-up master cylinder has a stepped bore for greater fluid flow along with a special valve designed to draw fluid back in when brakes are released. This, in turn, allows specially designed low drag brake calipers to quickly retract brake pads away from the disc - ensuring they do not linger there and create drag.

Resurfacing

The process of using a lathe to grind down the surface of a brake rotor or drum that has become warped and uneven. The outer metal surface is literally shaved away, leaving a smooth, flat surface that will mate properly again with brake pads/shoes. Minor hotspots on the surface of the rotor can effectively be ground off as well during this process.

Since metal has been removed from both sides of a disc brake rotor, the resultant thinner width reduces the rotor's ability to dissipate heat and makes it more susceptible to warping. All brake rotors have a specified minimum thickness; once the rotor is below that thickness, it must be replaced.

Rotor

On disc brake systems, the rotor is a circular metal disc that rotates with the wheel in order to provide a surface for brake pads to clamp against when stopping friction is required. Rotors are typically made from a single piece of cast iron, but some high-performance rotors feature two-piece construction with an aluminum center to save weight.

Rotors may or may not have finned cooling ducts in their centers, and those designed for higher performance may have slots, grooves or holes cut into their face for better dissipation of heat, debris, and water. To view OEM-style rotors we offer: click here. For performance-oriented rotors we offer: click here.

Runout

A wear condition when the surface area of a brake rotor or drum has become warped and uneven, similar to the way an old vinyl record can. As the rotor spins with the wheel, sideways variation occurs. Lateral runout can be checked by positioning a dial indicator against a rotor as it's spun by hand. More severe cases of runout will cause noticeable pulsation when brakes are applied.

Self Energizing Brakes

A drum brake layout where a larger brake shoe (primary) uses the rotation of the drum to apply pressure on a smaller shoe (secondary). This increases braking power and reduces the amount of physical effort needed to depress the brake pedal. Once brakes are released, a spring pulls the primary brake shoe back to its resting position.

Semi-Metallic Brake Pads/Shoes (a.k.a. 'Metallic')

A type of brake pad/lining material that uses metallic fibers (steel wool) as a main ingredient. Designed to replace asbestos pads, semi-metallic brake linings provide excellent bite, but cause more wear on rotors due to their grittier makeup. Their combination of lower cost and effective heat disbursement makes them a good fit for most production vehicles that see everyday street use. See pads or shoes for links to OEM-style and performance oriented semi-metallic brake pads.

Shoes (a.k.a. 'Brake Shoes')

Shoes are actually the metal brackets that drum brake linings are bonded to. These provide structural support for the linings, similar to the way backing plates do on disc brake pads. Often, brake shoes are sold as a one-piece item with linings attached. To view OEM-style brake shoes (complete with linings) we offer: click here.

Sliding Brake Caliper - See Floating Caliper

Slotted Brake Pads (a.k.a. 'Grooved Pads')

These feature one or more grooves cut into the surface of the brake pad to aid in disbursement of heat, dust/debris, and water during higher performance driving.

Slotted Rotor

Disc brake rotors with indented, shallow slots cut into both sides of the rotor faces. These slots allow more water, heat, brake dust, and friction gases to slide out from underneath the pads. Because slotted rotors stay cooler, they're ideal for aggressive driving and 4WDs that haul heavy loads or tow trailers. Since the slots are not deeply cut into the rotor, there is less risk of the disc cracking.

Solid Rotor

An unvented type of disc brake rotor with no cooling ducts in its center area. These are the opposite of vented rotors. Many of today's production vehicles feature vented front rotors and solid rear rotors as standard OEM equipment.

Star Wheel Adjuster

In a drum brake assembly, the star wheel is an adjuster mechanism that's turned by rotating a toothed wheel attached to it. As brake shoes wear, this adjuster moves them closer to the drums to ensure they maintain effective contact necessary for stopping power. Thanks to a specially designed hole in the back of the drum brake assembly, a fitted tool can be used to reach in and move the star wheel.

Two-Piece Rotor

Two-piece rotors feature an aluminum center section bolted to a traditional iron outer section where pads make contact. Because the center section is aluminum, a lot of weight is saved and quicker brake response is achieved. It's hard to confuse a two-piece rotor with anything else because bolts that lock the two pieces together are highly visible, and center sections usually have a different-colored finish in order to heighten their appeal.

The center section is sometimes referred to as a "hat". Two-piece rotors are more expensive and are typically available on high performance vehicles. Traditional rotors without two separate pieces could be referred to as "one-piece", but that term is not widely used.

Vacuum Bleeding

A special vacuum tool is used at the wheels to vacuum old fluid out of the brake lines through bleeder screws. It works much the same as power bleeding, but since there's no pressure pump attached to the master cylinder, no vehicle-specific adapter pieces are used. See also "brake system bleeding".

Vacuum Booster, (a.k.a. 'Power Brake Booster')

The vacuum diaphragm unit in a power brake system that multiplies the force exerted on the brake pedal to the master cylinder. Pressure for the vacuum booster is supplied by a line that's connected to the engine intake manifold. To view vacuum boosters/power brake boosters we offer, click here.

Vented Rotor

A disc brake rotor with cooling fins between its faces. These cooling fins improve heat dissipation and generally provide improved braking ability under higher-performance driving conditions. Most production vehicles feature vented front rotors and solid rear rotors as standard OEM equipment.

Wheel Cylinder

Component in a drum brake setup with two pistons that extend outward as brake fluid pressure increases. As the pistons extend outward, both brake shoes are pressed against the rotating drum to create stopping friction. To view wheel cylinders we offer, click here.