Disc brake rotors (aka 'rotors') are the actual discs that brake pads clamp onto, creating friction that slows a vehicle. Disc brake rotors bolt on over the axle hub and contain holes that allow wheel mounting bolts to pass through and rotate with the wheels.

Since there are many rotor styles and designs specially created for every budget and need, we've listed the advantages of each disc brake rotor so that you can make the right choice and get the best for your vehicle. All rotors, except ceramic brake rotors and two-piece rotors with aluminum centers, are typically one piece and crafted from iron which can tolerate the repeated cycles of heat absorption and dissipation.

OEM Style Rotors

As a rule, OEM style rotors are standard equipment on most vehicles, and are also the most basic style available. As opposed to performance-oriented rotors, the OEM ones have a smooth pad contact surface with no grooves or holes for heat dissipation.

For those who are going to use their vehicle for everyday driving rather than aggressive road racing, basic OEM style rotors are just the ticket.

What Is A “Ventilated” Rotor?

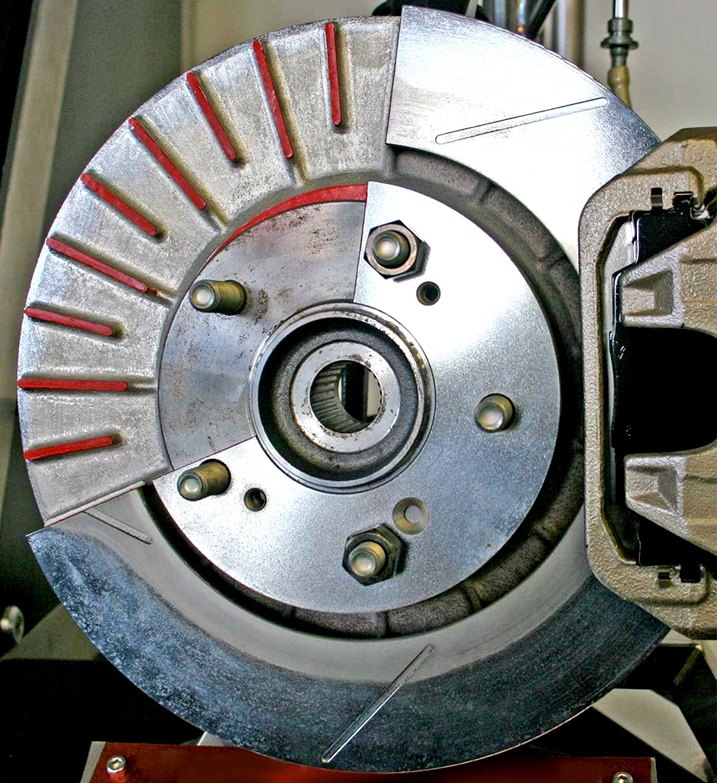

If you’ve heard the phrase “vented” or “ventilated” rotor and wondered what it referred to, let us explain. This doesn’t describe the rotor face surface. Rather, it refers to an open center area between rotor sides. Within this center area are fins of various shapes designed to pull air through them and remove heat from the rotors. Shedding this heat is critical to ensuring that the brakes continue to operate correctly. It also minimizes the likelihood of overheating, or boiling, the brake fluid. Most OEM front disc brake rotors and all performance rotors feature ventilated centers between rotor sides.

Typically, OEM style rotors feature straight, parallel cooling fins. Depending on the make and model, rear disc brake rotors are either vented, or 'solid' with no cooling space between rotor sides. By and large, solid rotors are adequate for rear applications because less of the work stopping the vehicle is done there and they don't heat up as much.

Some performance-oriented brakes have curved cooling fins instead of straight, parallel ones. Because curved fins only function efficiently in one direction, this rotor type is labeled unidirectional and feature opposite designs for right and left sides. Other styles of ventilated rotors may feature tear drop-shaped pillars between rotor sides instead of fins to create more metal contact and ensure better heat dissipation with the same airflow.

'Slotted' (aka 'Grooved') Rotors

'Slotted' (aka 'grooved') rotors are designed for the enthusiasts who expect better bite from the brake pads, especially during aggressive driving or towing. Two sets of indented, shallow slots, across the side of each rotor, allow water, heat, brake dust, and friction gases to slide out a lot easier from underneath the pads. They stay cooler during aggressive driving and are perfect for 4WDs that often haul heavy loads or tow trailers because the slots are not deeply cut into the rotor.

As a result, the rotor retains its mass and strength without fracturing or warping under heavy-duty use. Considering that these slots slice away more pad material on contact, it's fairly typical for this type of rotor to have slightly lower pad life.

'Drilled' Disc Rotors

'Drilled' disc rotors are definitely a step ahead of slotted ones when it comes to high performance driving. Most drilled rotors feature holes that reach through to the other side – a layout that ensures maximum disbursement of heat and debris generated under heavier use. Some drilled rotors also feature a slotted design. With or without slots, drilled rotors are great for use on performance vehicles that are typically driven hard.

A disadvantage of drilled rotors appears right when those are used on a vehicle that takes on a greater weight load due to hauling of heavy cargo or sustained towing. Vehicles with built-up engines or superchargers can also have a damaging effect on drilled rotors, especially when abused by either stunt driving or drifting. Since the drilled holes take mass out of the rotors, it is possible for cracks to occur between the perforations.

Rotor surfaces with holes that have been partially drilled through are also known as 'dimpled'. While they reduce the risk of cracking, dimpled rotors sweep away less heat than fully-drilled ones do. To offset this loss, dimpled rotors usually feature slots as well.

'Ceramic' Rotors (aka 'Carbon Ceramic')

'Ceramic' rotors (aka 'carbon ceramic') are not made of iron, but a special blend of porcelain compound materials. First used on the production version of Porsche's 2001 911 GT2, their popularity as original equipment on high-end performance models has steadily grown. So if your vehicle wasn’t originally equipped with carbon ceramic disc brake rotors, it’s worth a look to see if we’ve got them for the make and model you drive.

Ceramic brakes cost more, yes. But when it comes to corrosion resistance, sheer stopping power, and ability to withstand heat, ceramic rotors are heads and shoulders above iron ones. In fact, availability of aftermarket ceramic brakes is lower than any other kind because their high cost and associated exclusivity puts them in the 'unique' category.

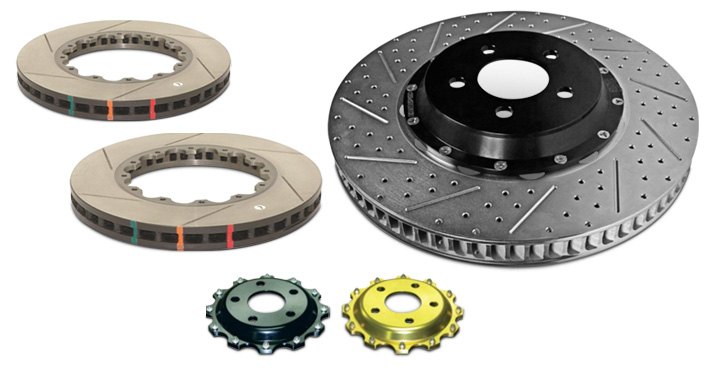

Two-Piece Rotors

If you're looking to achieve quicker brake response, 'two-piece' rotors are exactly what you need. Unlike most disc brake rotors which are one-piece units, two-piece ones feature an aluminum center section bolted to a traditional iron outer section for solid pad contact. Because the center section is aluminum, a great deal of weight is saved.

It's hard to confuse a two-piece rotor with anything else because bolts that lock the two pieces together are highly visible, and center sections usually have a different-colored finish in order to heighten their appeal. Two-piece rotors are more expensive and are typically available on high performance vehicles. If that's not an issue, they are great for offsetting the heavier weight of larger wheels and tires.

Rotor Finishes

Finishes on rotors can vary as well. Since iron is subject to corrosion, most such rotors are coated with some form of anodizing, paint, or powder coat to keep rust at bay on areas that don't see pad contact. Rotors will arrive completely coated with the finish of choice – but not to worry, the top layer will scrub off immediately upon contact with brake pads without impeding stopping ability. No rotor will stay nice-looking for a lifetime, but a sure bet for vanity is a two-piece rotor with a corrosion-free aluminum center section.

We’ve set up our main brake rotors page with a series of check boxes along the left side of the screen designed to make your product search easier by narrowing down products that appear to match those selected. These allow you to see rotors designed with OEM or performance characteristics, plain/slotted/drilled/or dimpled faces, rotor materials, and 1- or 2-piece construction. Additionally, you can choose brakes geared toward different styles of driving as well as caliper construction.

If you’re really interested in upgrading your vehicle’s stopping power, we also invite you to read our related articles on performance brake pads, performance kits that include pads, rotors, and calipers, and special tools used for brake service. And we welcome any inquiries you have by phone. We’ve got knowledgeable product specialists on call seven days a week! We look forward to doing business with you!