Ask any professional automotive tuner or hot-rodder about the stopping power of drum brakes, and they'll tell you to ditch the drums completely and make an upgrade to disc brakes. This kind of swap is performed often in the automotive world, especially on collector cars that have some power behind the wheel.

In fact, it's so commonly done that major component manufacturers have been producing brake conversion kits for years - kits that deliver smooth, even stopping power because all the bugs have been meticulously worked out. In this article, we'll cover such drum-to-disc brake conversion kits for popular vehicles from the 1950s through the 1980s, and we'll discuss the benefits you'll enjoy after making the switch.

A Look At The First Cars Equipped With Disc Brakes Tells You All You Need To Know

While the earliest forms of disc brakes had been undergoing experimentation and development since the 1890s, the first reliable applications of caliper-style disc brakes as we know them today appeared in the 1950s. For example, a Jaguar fitted with front discs was able to beat Ferraris, Maseratis, Porsches, and other exotics in the 1953 LeMans 24-Hour Race, averaging over 100 miles per hour thanks to superior braking capability around turns.

Austin-Healey joined Jaguar that year by offering 4-wheel-disc brakes on production models. Other early adopters of disc brakes were Citroen (1955), Triumph (1956), Jensen (1956), Mercedes (1961), Studebaker Avanti (1963), and Chevrolet Corvette (1965). Notice a pattern here?

These were all sports cars that prided themselves on nimble handling and responsiveness of all mechanical systems - with effective stopping power being a big part of the formula. Disc brakes were a natural fit on these vehicles for the same reason they've become mainstream today - their benefits and performance are far superior to drum brakes.

Disadvantages Of Drum Brakes

More Heat Buildup Hurts Braking Power

Unlike disc brake rotors and pads that are completely exposed, brake drum assemblies feature an enclosed design with virtually no airflow to cool things down. Instead, heat builds up and radiates to the brake drum and backing plate. After repeated brake applications, heat buildup can cause the radius of the drum to swell more than the radius of the brake shoe making contact with it. The contact patch that the brake shoes have against the drum shrinks, and braking power can drop by up to 20 percent.

Because disc brakes dissipate heat more rapidly, brake fluid also stays cooler and does not boil in the lines as quickly. This enhances drivability - because when boiling fluid become aerated and bubbly, you're left with a spongy-feeling pedal and brake pressure that seems only half-strength.

Disc Brakes Perform Much Better In Bad Weather Conditions

The encapsulated design of drum brake systems makes it difficult for water to be expelled out of the drum during rain or bad weather conditions. And if you drive through a large puddle of water, forget it! When water collects inside a drum, it's there to stay for a while until the system dries out. During this time, water that's present reduces friction between brake shoes and drums, and severely cuts braking power. In winter temperatures, melted slush caught in the brake drum can freeze overnight, causing spotty and erratic brake performance until friction warms things up.

Because disc brake components are out in the open, bad weather concerns are minimal because water and slush are simply whisked off the rotors completely whenever pads make contact. Needless to say, the consistent and reliable level of stopping power that disc systems provide in wet weather conditions increase safety many times over, and it reduces the odds of damage to your vehicle due to loss of control.

Drum Brakes Are More Labor Intensive To Work On

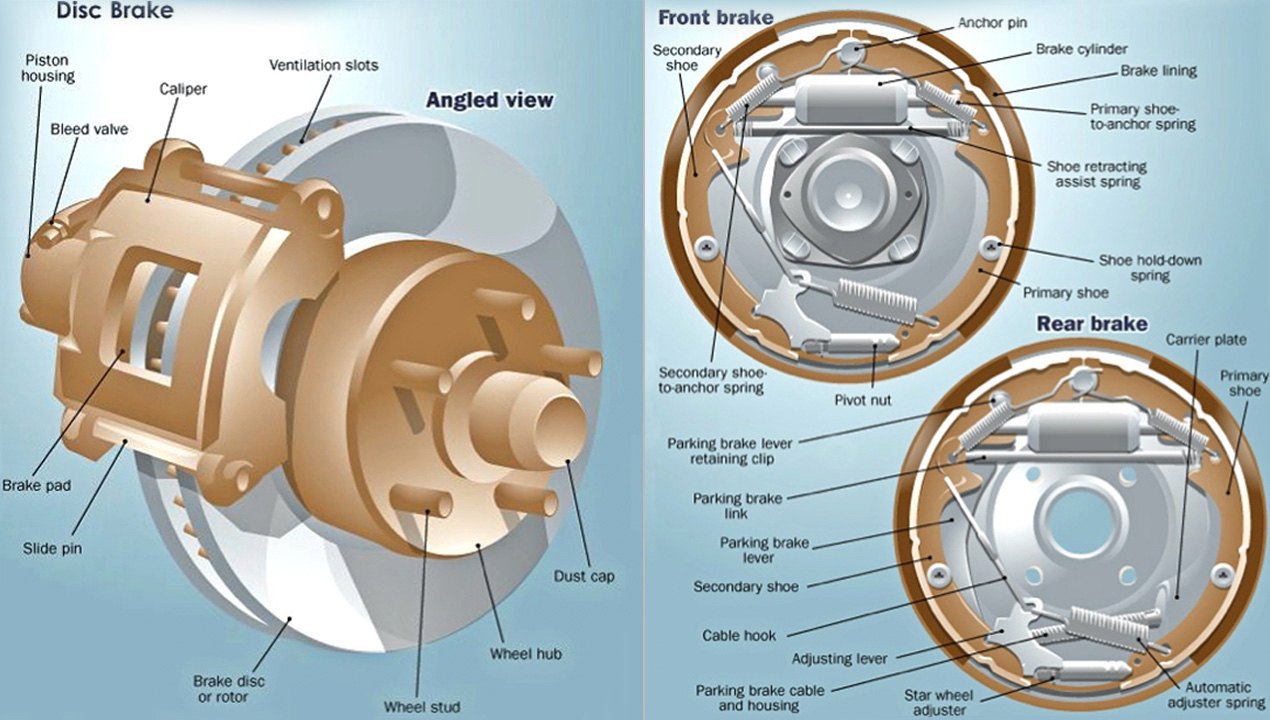

With just a quick look at the diagrams further above, it's easy to see how much more complicated a drum brake assembly is compared to a disc brake setup. The multitude of clips, springs, pivot nuts, and adjuster component parts on drum brakes may cost less to produce as a whole, but they make repairs very time-consuming. Plus, drum brakes require constant adjustments to maintain their full braking power, while disc brakes require no adjustment at all.

A Brief Description Of The Drum-To-Disc Swapping Process

For the mechanically inclined, the process of switching over to disc brakes is not overly complicated. Depending on your specific vehicle layout, you may also need to replace the brake fluid master cylinder - but not in every case. And should you choose to have a professional mechanic install your kit, the labor costs won't be excessive because major surgery is not being performed.

We won't go into detailed steps regarding the installation process because instructions will vary from vehicle to vehicle. However, we've summarized the basic steps involved in order to help make the product selection process a little more understandable.

If your car is rear-wheel drive and you're converting a rear drum brake set, you'll basically be unbolting the brake drum and its backing plate assembly from a flange on the rear axle housing along with the brake fluid lines and any emergency brake cables. In order to do this, you may need to temporarily remove the axle shaft itself. Once all components have been unhooked, you can bolt on any mounting/backing hardware for your new disc brake calipers. Then you'll bolt your new rotor in place, connect the brake lines to your new calipers, position your calipers over the rotor, then attach the calipers to backing plate pieces that came with the kit.

If you're swapping out front drums on a rear-wheel-drive car, or rear drums on a front-wheel-drive car, you'll be working on non-drive wheels. Such wheels will be equipped with needle-shaped spindles that OEM drum brake assemblies are mounted to. After removing the center dust cap, wheel bearing race (if your vehicle is equipped), and spindle nut that holds your old drum brake assembly in place, you can remove the old brake components.

Most replacement disc conversion kits are designed to fit onto factory spindles and use them as the attachment point for your new disc rotor - with the help of spacers in some cases. However, other kits with rotors oriented more toward performance may come complete with their own replacement spindles. If your kit includes replacement spindles, use them.

When you're making your selection in our Product Options field, you may be given a choice of 2" drop spindles or 0" spindles, for example. A "drop spindle" effectively lowers the ride height of your vehicle by positioning the spindle needle higher than the OEM factory location. Once the wheel is installed on that higher spindle needle, the rest of the vehicle will sit lower as a result. Unlike shorter springs, this allows a vehicle to be lowered while retaining factory suspension travel and comfort. As it sounds, a 2-inch drop spindle will lower ride height by 2 inches.

Narrow Your Product Search By Entering Specific Details

To best browse our selection of products, we recommend starting at our main page for the Disc Brake Conversion kits section. At the top of the screen above products that are listed, you'll see drop down boxes where vehicle year, make and model should be entered. You'll also see a series of check boxes for different product categories at the top left corner of the screen.

These boxes will let you narrow your search as little or as much as you prefer - and it is not necessary to check off boxes in every category. More than one box in each category can be selected if you choose to see a greater number of products. Note that as you check certain boxes in one category, selection boxes in other categories may disappear if criteria proves mutually exclusive.

After choosing either front or rear wheel kits, you'll be able to select those with the grade of performance you'd like - from "daily driver" level to "track only" with the most extreme stopping power.

Next, you'll be able to select whether you're looking for "Big Brake Kits" with larger-diameter rotors that visually enhance the space between big rims you've fitted, or if you're looking for drum-to-disc conversion kits. Selecting both boxes will let you see conversion kits that come in larger sizes with beefed up components.

After that, your search can be narrowed to rotors that feature "drilled", “slotted”, "drilled and slotted", or plain faces (see our Glossary of Brake Terminology for more details). Another check box heading allows you to choose between one-piece rotors that match OEM all-iron construction, or two-piece rotors with an aluminum center section. It's important to remember that the selection of vehicles that two-piece rotors are built for is somewhat limited. There are many one-piece rotors that will give you a noticeable boost in stopping ability, so don't rule them out.

Lastly, you'll be able to choose between kits that include calipers with a varying number of pistons as well as "fixed" or "floating" designs. For more details on these terms, see our Brake Glossary referenced further above.

Conversion Kits We Offer

For starters, we've got the Right Stuff Drum-to-Disc Conversion Kit for street-driven General Motors and Chrysler vehicles from 1955-88. Note that for many vehicles originally equipped with 4-wheel drum brakes, you may be given a choice among "front conversion", "rear conversion", and "front and rear conversion" kits. This kit provides new master cylinders on applicable vehicles, and it offers you a choice of chrome or zinc-coated finishes for the master cylinder housing. Depending on make and model, calipers in the kit may only be available with a clear powder coat layer, or you may be able to select red or black powder coat. At a lower price point is the Right Stuff Mini Conversion Brake Kit which includes only new spindles, brackets, and backing plates.

For more recent cars and trucks equipped with rear drum brakes, the SSBC Stock Drum-to-Disc Brake Conversion Kit features OEM-level replacement calipers and rotors. These are great for normal street driving. For a higher level of braking performance, check out SSBC’s Super Duty Brake Conversion Kit.

If you're looking to convert to a disc brake set with a higher level of stopping power, we've got several kits. Choose the Baer SS4 Plus Drum-To-Disc Drilled & Slotted Conversion Brake System for lighter weight vehicles or the SS4 Plus Deep Stage Drum-To-Disc Drilled & Slotted Conversion Brake System for heavier vehicles up to 3,200 pounds. Rotors are two-piece design with lightweight aluminum centers, and aluminum calipers come pre-loaded with ceramic brake pads.

For those who anticipate using their vehicle for longer-duration track racing events, the Wilwood Street Performance Carbon Ceramic Drum-to-Disc Conversion Kit features two-piece lightweight rotors made of carbon ceramic material which is extremely resistant to heat buildup. This ensures stopping power remains steady and strong even under grueling conditions. Choose kits with aluminum calipers finished in black, red, or nickel plate.

For track-only cars that won't see street driving, Wilwood's Drag Race Drilled Rotor Drum-to-Disc Conversion Kits (see choices on our Wilwood page) feature perforated rotors with black electro-coat finish, new wheel hubs, bearings, and aluminum caliper housings. For the purposes of saving weight, rotors are thinner and built with less material. This makes them suitable for single-purpose stops at the end of a drag strip run, but not for everyday street driving. If you prefer this kit with equally thin rotors that are plain faced instead of drilled, we've also got Wilwood Drag Race Plain Drum-to-Disc Conversion Kits.

And if you've got a pre-2007 Jeep Wrangler built with rear drum brakes, we've got Crown Brake Conversion Kits with one-piece rear disc brake rotors.

Once you're driving your classic with disc brakes for the first time, you'll realize just how transformed it feels - and how much easier it is to control. The increased stopping power means you no longer have to plan stops way in advance, and you won't have to break a sweat on a crowded highways worrying about whether traffic from on-ramps is going to allow you to pass or suddenly cut in front of you. Plus, those beautiful new brake calipers will look so much better behind a set of custom rims. And even if no one else sees your new brakes, you'll know they are there!