Toyota Parts

Toyota Parts

Featured Products

-

$38.95 - $1,543.95Save: up to 10%$37.00 - $1,451.31

$38.95 - $1,543.95Save: up to 10%$37.00 - $1,451.31 -

$106.83 - $2,210.33

$106.83 - $2,210.33 -

$455.99 - $5,334.99

$455.99 - $5,334.99 -

$25.41 - $86.69

$25.41 - $86.69 -

$249.99 - $999.99

$249.99 - $999.99 -

$43.81 - $781.71

$43.81 - $781.71 -

$21.95 - $384.95Save: up to 15%$21.29 - $361.85

$21.95 - $384.95Save: up to 15%$21.29 - $361.85 -

$4.51 - $93.48

$4.51 - $93.48 -

$2.13 - $950.04

$2.13 - $950.04 -

$51.95 - $132.95Save: up to 6%$49.87 - $126.30

$51.95 - $132.95Save: up to 6%$49.87 - $126.30

All vehicles by Toyota are well-designed and have unrivaled record for durability and reliability. If you are a Toyota driver you certainly will need to find a reliable and quality replacement parts sooner or later. With the extensive collection of auto repair parts for Toyota offered on CARiD, you will restore your vehicle to the original condition, ensure its long service life and smooth and reliable operation as well. All products at CARiD are of the finest quality and manufactured by the most reputable companies in the industry, constructed from premium materials and designed to comply with the toughest quality and safety standards.

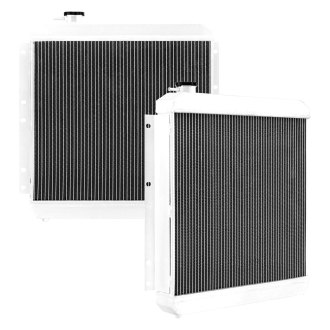

Emission control parts, air intake parts, exhaust parts, engine cooling parts, suspension parts, brake parts, driveline and axles – all these products are of superior quality and OE matched. CARiD is the distributor to trust as we have a complete understanding of what your vehicle is all about and always ready to help with any question. With our wide selection of auto replacement parts we will help you to solve any problem and ensure long service life of your four wheel friend.

Browse by Model

Popular Products

-

$74.61 - $88.84

$74.61 - $88.84 -

$48.00 - $54.94

$48.00 - $54.94 -

$429.95 - $470.95

$429.95 - $470.95