So you’ve decided to take on the project of rebuilding or replacing your vehicle’s engine. Modern internal combustion engines are quite complex – with a wide array of components that rotate, move up and down, pump, seal, or remain stationary. But don’t let that dissuade you from giving it a try if you’re a beginner. No one is born knowing how to rebuild or replace an engine, and there’s no reason you can’t learn the same way anyone else has – by doing it!

This article cannot cover every possible variation without becoming a textbook. But at a high level, one of the earliest decisions you’ll need to make is:

Should I Rebuild My Exisiting Engine, Or Replace It With A Remanufactured Engine?

There are pros and cons to each choice. First, is your old engine rebuildable? Not all are. If the block is cracked or otherwise severely damaged, rebuilding it is likely not an option. Are the needed internal parts available? The aftermarket does a great job in supplying components for the more popular engines. However, you may want to first check availability. On a more practical level: What is your skill set, and how much time do you have? The rebuilding process usually requires machine work, so even if you’re taking a week off to perform the rebuild, the outside work may slow you down. Rebuilding may make the most sense if you’re sure that the block can be reused, if the needed parts are available and affordable, and if you have the time and talent.

On the other hand: Why not consider a rebuilt (remanufactured) engine? Most “remans” are done by reputable companies and are accompanied by a warranty. In simple terms, you pull your old engine, and drop in the new one. (In reality, there are a number of components to switch over.) Reasons why you might not want a reman unit include cost (likely higher than rebuilding an engine yourself), availability (you might not have a choice if no remans are out there), and the logistics of getting a 600 lb. engine off a freight truck and returning the old one for core credit. It’s a very individualistic decision, so we’ll proceed and talk about BOTH rebuilding and replacing.

The Main Sections Of An Engine

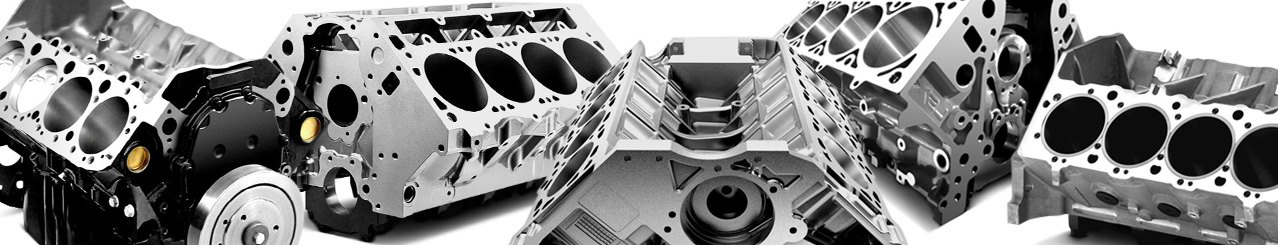

A typical motor vehicle engine consists of two major sections - the engine block on the bottom and the cylinder head (or heads) on top of the block.

The engine block is home to the crankshaft, pistons, connecting rods, and related smaller components. For a long period, especially with American cars, blocks were cast from heavy, durable iron. The iron surface was ideal for cylinder walls against which the pistons moved up and down. In more recent decades, especially as efforts grew to reduce weight, manufacturers switched to aluminum for the block material, and used iron cylinder sleeves for durability and reliability.

Cylinder heads contain intake and exhaust valves, tappets, and valve springs. So-called “overhead cam” engines have the camshaft located in the head. Cylinder heads are also home to the spark plugs. Inline engines (all the cylinders lined up in one row) have one cylinder head. Engines with more than one bank of cylinders (so-called V-, W-, or H- engines) have two cylinder heads, one for each bank.

Engine Hoists Enable Engine Removal In Your Garage

Whichever job you’re embarking on, you’ll need to start by pulling the existing engine out of your vehicle. Most DIYers use an engine hoist, also known as an engine crane. Let’s look at some engine hoists found in our engine hoists and stands section.

For removing an engine in your own garage, basic engine hoists rated for 1 or 2 tons of lifting capacity will be more than suitable for the job. These are built with a sturdy metal frame, hydraulic pressure cylinder, and jack handle that’s used to ratchet the engine straight up out of the engine bay – supported by chains (sometimes described as “slings”) and hooks bolted to factory holes or brackets on the engine. Sturdy casters on the bottom of the hoist allow the user to roll it and the engine, now suspended in mid-air, away from the immobile vehicle.

Some hoists may be equipped with a telescopic boom extension that’s useful for certain vehicle and engine configurations. When you need to tilt the motor diagonally, boom extension pieces fitted with a load leveling bar (see next section below) allow you to effectively work at awkward angles without struggling.

For good value and capacity that will fit most needs, we recommend the AFF Folding Engine Crane (2 tons) with 4-position telescopic booms, ATD 2-Ton Folding Engine Crane, OTC Folding Floor Crane (2 tons), and Torin Big Red Engine Hoist (choose 1 or 2 tons).

Load Leveling Bars

When your engine is supported by chains on both sides, it can tilt to one side if the weight is unevenly distributed. This poses challenges when removing an engine. To correct this, an engine load leveling bar allows you to move the horizontal support bar left or right as needed to balance and straighten out a lopsided load.

Some load leveling bars are included with hoists. If you need a leveling bar, we’ve got great values with the Torin Big Red Engine Leveler (rated for 1,500 lbs) and the Power Team 2000 lb Load Rotors Tilter. The weight capacity of those levelers should be fine for any passenger car or light truck engine. For even heavier loads, we’ve got the Power Team Load Rotors Tilter (choose 2- or 3-ton capacities), Hein-Werner 3-Ton Load Leveler, and OTC 6000 lb Capacity Load Leveler.

Power Pullers

If you don’t need an engine crane because you have an existing overhead structure strong enough to support the weight of an engine, check out the power pullers in our Hoisting Equipment subsection. These are portable ratcheting assemblies that can be used anywhere (off-roaders often use these to pull themselves out of ditches). You’ll also find a variety of chains, hooks, straps and other useful items there. Keep in mind that getting the now-removed engine off the power puller may be more of a challenge than with a hoist.

If You’re Replacing The Engine With A Reman Unit

"Short Block", "Long Block", or "Complete Assembly"?

When you're looking to purchase a replacement engine, it's decision time again. The aftermarket may offer you choices including "short block", "long block", and "complete assembly" (sometimes known as "crate engine" or "OE engine").

Here's the lowdown on the terms "long block" and "short block". The words "long" and "short" do not refer to the size, length, or displacement of the block. Rather, they refer to the relative completeness of the assembly. Most of the engine assemblies we offer are long blocks.

Short Block

By definition, a "short block" includes the block and its internal moving parts (crankshaft, pistons, connecting rods, and camshaft if so equipped), but does NOT include cylinder heads or oil pan. You can think of it as including nothing above or below the top and bottom surfaces of the block.

Long Block

By contrast, a "long block" includes everything which is in the short block, PLUS cylinder head or heads and valve train. In some cases, the oil pan and valve covers are part of the long block.

The typical long block installation still requires re-use of a number of engine components including intake and exhaust manifolds, fuel system, and engine-mounted ancillaries such as the starter, alternator, and power steering pump.

Complete Assemblies (Crate Engines, OE Factory Engines)

Under Replacement Engines and Engine Parts on our website, we distinguish between "Engine Blocks" and "Engine Assemblies". Both short- and long-block engines are listed under Engine Blocks. Engine Assemblies is where you'll find complete assemblies, OE replacements, and crate engines. All three are variations of the same theme.

An engine assembly takes the long block and typically adds intake manifold, valve covers, oil pan, water pump, and crank pulley. Some rebuilders will also include exhaust manifolds and ignition distributor. Obviously, this adds to the cost; however, there's less labor to swap parts over, and the engine is closer to "ready to go".

Among the various short blocks, long blocks, and complete assemblies on our site, we have the Replace OE Replacement Engine for a wide range of makes back to the 1960s, the Dahmer Powertrain remanufactured Long Block Engine (select American makes back to the 1960s), and Genuine Crate Engine (late model Mini Coopers). We've also got new OE-specification long block engines from Mopar (1998-on Chrysler, Jeep, Dodge vehicles) and Motorcraft (1979-2003 Ford trucks and vans).

Once you've entered the year, make, model, and original engine of your vehicle, you'll see any applicable fitment notes that apply. You may also be prompted to enter your full 17-digit VIN and current mileage. This is to ensure 100% compatibility, as well as to document the mileage at the time of replacement.

New Complete Engines Built for Higher Performance

We understand the desire for more power. While the thrust of this article is intended to cover OE-equivalent replacement and rebuilt engines, we would be remiss if we did not inform you of the wide selection of performance engine assemblies available at our Performance Parts Department. Follow the link to check them all out!

If You’re Rebuilding Your Engine

If you plan to disassemble your existing engine down to the bare block and rebuild with new or remanufactured components, you'll need a few things.

First, You'll Need An Engine Stand

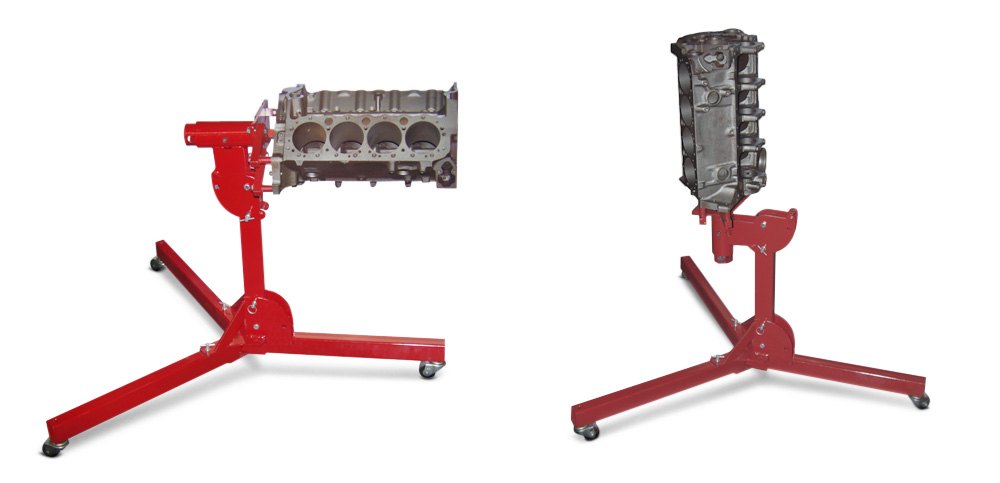

Once you get the engine out and away from the vehicle, you'll need to get it off the hoist. After all, you can't effectively work on it while it's hanging from a chain and swinging like a pendulum in midair. An engine stand allows the engine block to be bolted to it - affixed firmly and securely in place. Most stands offer the ability to rotate an engine block to any position so you can easily access all sides of it.

Among our engine stands, we recommend the AFF Engine Stand (1,000 lb), Auto Dolly Folding Engine Stand (1,200 lb capacity), Hein-Werner Engine Stand (1,250 lb), and the Sunex 1-Ton Folding Engine Stand (2,000 lb) just to name a few. Should you need heavy-duty capacity, the OTC Engine Stand is available in 1,000- or 6,000-pound capacities.

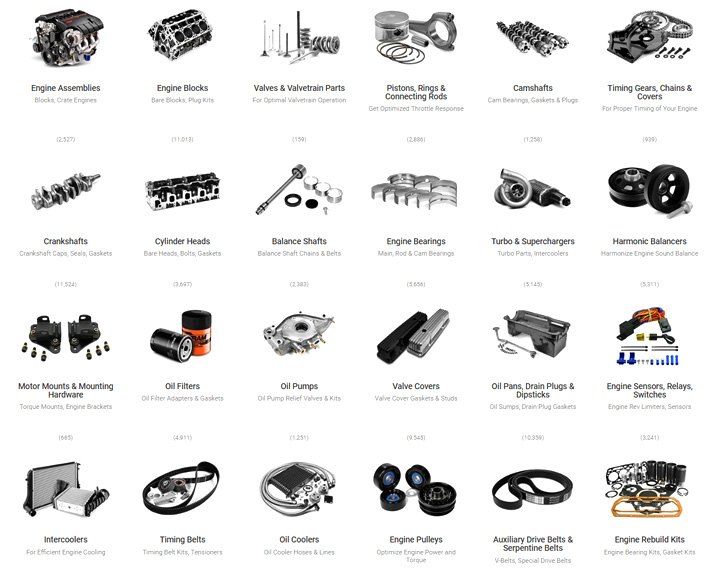

New Components Needed For An Engine Rebuild

When ordering internal parts for your engine, you'll come across many different terms. You may find our Glossary of Engine Internal Parts helpful in understanding what many of them are. Below, we discuss which parts are typically replaced if you plan to disassemble your current engine and do an internal rebuild, and we'll guide you to where they can be found on our website.

Within the engine block, typical wear items which are replaced during a rebuild include pistons, piston wrist pins, piston pin bushings, piston rings, rod bearings, and main bearings. Crankshafts are machined if possible, and are replaced if they cannot be machined. Connecting rods can be reused or replaced. The block may also need new expansion plugs and oil galley plugs.

You may find for sale complete cylinder heads (with related camshafts and valves found within), and you'll still need cylinder head gaskets, valve covers, valve cover gaskets, oil pans, oil pumps, harmonic balancers (if equipped), and timing covers. If you are rebuilding your existing head, you want to consider new intake and exhaust valves, valve springs, rockers, push rods, and their associated hardware. You'll need new head bolts in order to clamp the heads to the block.

Some additional engine needs include water pumps, valley pans & related gaskets, throttle body assemblies, and flywheels.

In our Engine Rebuild Kits sub-section, you'll also find engine seal kits, gasket sets, and hardware kits such as the Dura-Bond Engine Hardware Finishing Kit.

It's beyond the scope of this article to include any discussion of examining and measuring parts for wear. Here's our best advice: While you may be able to perform much of the disassembly and reassembly yourself, investigate the talents of a professional who can perform such inspections and measurements for you. Engine machine shops may offer such services. This way, you'll be certain to replace only the worn parts while still reusing any serviceable existing parts.

Once a remanufactured or properly rebuilt engine is installed in your vehicle, it will sound, feel, and perform like new again. Gone will be leaks, unwanted noises, tailpipe smoke, weak compression, misfires, and other ills to which you've grown accustomed. Back for your driving enjoyment will be smooth power delivery and reasonable fuel economy. The improvements will boost your vehicle value significantly. Just remember to break it in easily!