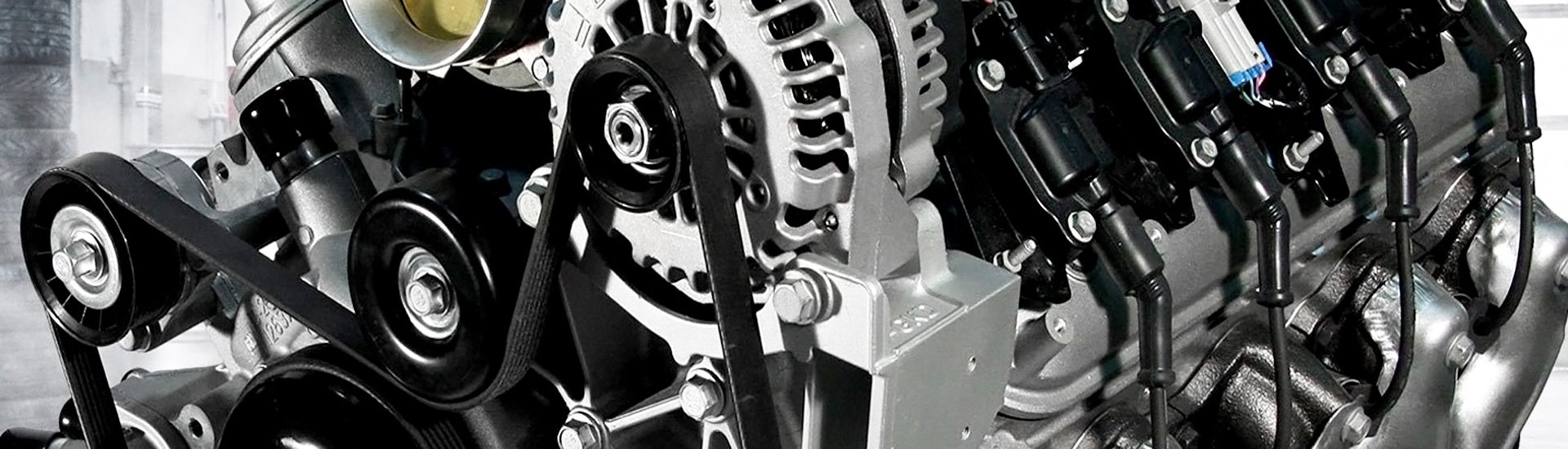

An engine that uses liquid fuel to create energy, such as an internal combustion engine, is basically a large air pump. Cool air is drawn in, mixed with the fuel of choice to create power, then expelled as hot exhaust gas afterward. The more efficiently this “air pump” of an engine breathes, the more efficiently it produces power.

In this article, we’ll focus on exactly how an automotive internal combustion engine transforms air and fuel into power to move your vehicle down the road. We define some terminology for various parts in this article – however, you may find our related article Glossary of Engine Internal Parts helpful if you’re interested in learning about other components not covered here.

Please keep in mind that this is a complex subject; while we have done our best to explain this in layperson’s terms, some concepts can be difficult to demonstrate in a two-dimensional format. Also, some descriptions of engine functions have been simplified for the sake of clarity.

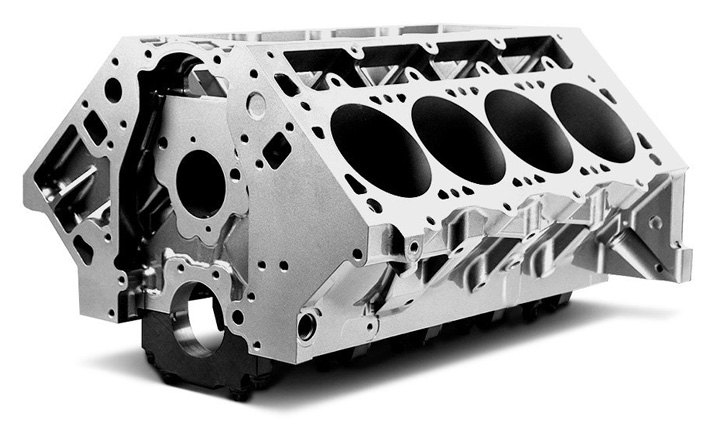

What Are The Main Sections Of An Engine?

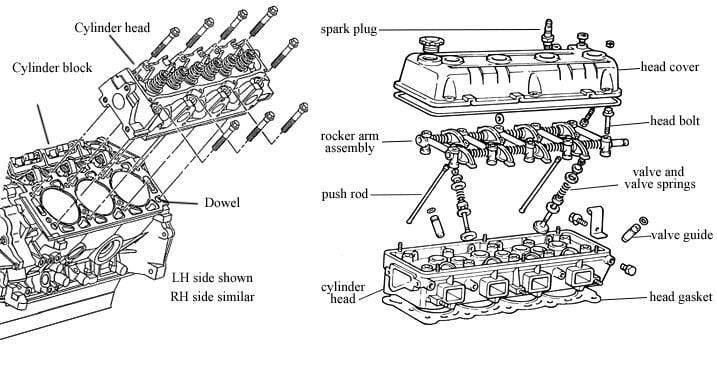

First, let’s examine the two main sections of a typical combustion engine. The main piece, and the largest one, is the engine block which makes up the lower section of the engine. It’s home to the pistons, connecting rods, crankshaft, oil pump, and camshaft if the engine is an “overhead valve” design. Because this section contains the cylinder holes where the pistons travel, it’s sometimes referred to as the cylinder block.

Bolted to the top of the engine block is a cylinder head (or heads). These contain exhaust & intake valves, and camshafts if the engine is an “overhead cam” design. Inline engines (cylinders all in one row) feature only one single cylinder head. Engines which are “V” shaped or “H” shaped have two cylinder heads, one per bank of cylinders.

How Does Air Get Into A Sealed Engine Block?

Before we look at the steps which make up the internal engine combustion process, it’s important to understand how air enters a sealed engine block in the first place.

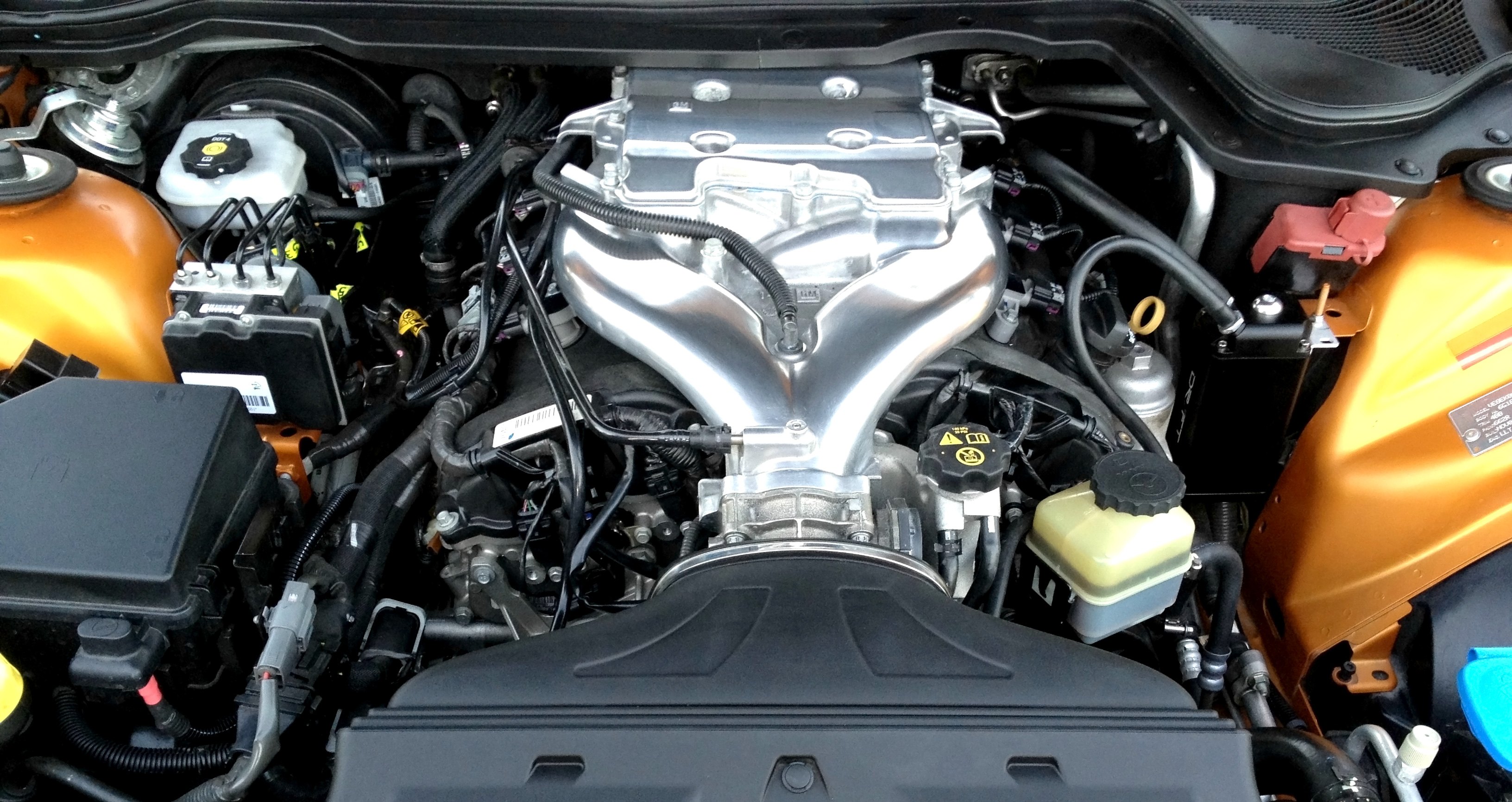

This occurs thanks to what’s known as an intake manifold. An intake manifold, made of metal or plastic, is an assembly that sits atop the engine, consisting of a series of tubes which distribute both air and fuel to each cylinder. (For more details about intake manifolds, we invite you to read our related article on the subject.)

After air first passes through an air inlet tube and is cleaned by the air filter, it enters the intake manifold. A carburetor, throttle body, or fuel injectors inject a corresponding amount of fuel, which mixes with this inlet air. The ideal ratio for an air/fuel mixture is 14.7-to-1, meaning 14.7 parts air to 1 part fuel. Now we need to get this air/fuel mixture into each cylinder. That is the start of the “4-stroke cycle” for our vehicle’s engine.

What Are The 4 Steps Of The 4-Stroke Cycle?

Automobile engines are described as “4-stroke” engines because 4 basic steps are involved in the process of combustion. (There are “2-stroke” engines, but those have not been used in a road-going car for many decades, and that discussion is beyond the scope of this article.)

So we are clear: the steps described below must happen in EACH of the engine’s cylinders. For clarity, we will describe the four strokes as they occur in a SINGLE cylinder.

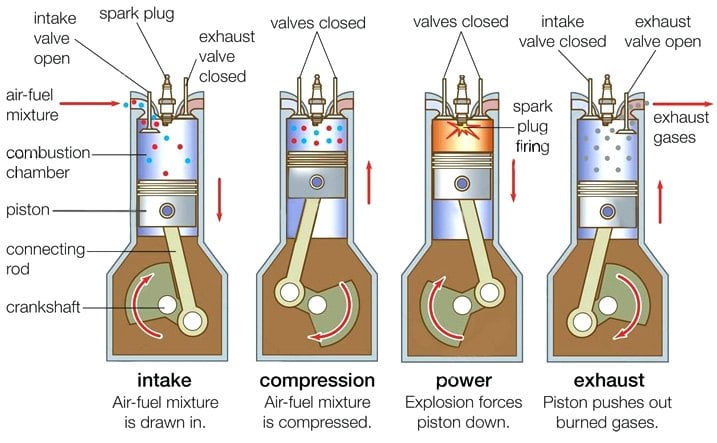

First Step: The Intake Stroke

The engine needs the fuel/air mixture to enter the closed cylinder area. For that to happen, the intake valve moves from a closed position to an open position. The mixture enters the cylinder. The piston, which is at the top of the cylinder, begins to move down, creating a partial vacuum which helps draw in the mixture. The exhaust valve remains closed during this step.

- INTAKE STROKE:

- PISTON MOVEMENT: DOWNWARD

- INTAKE VALVE: OPEN

- EXHAUST VALVE: CLOSED

- ACTION: DRAW IN AIR/FUEL MIXTURE

Second Step: The Compression Stroke

After the piston reaches the bottom of the cylinder (known as “bottom dead center”), the intake valve closes and the piston begins moving upward, which compresses the air/fuel mixture. Pressurizing the mixture will make it combust with greater force than if it weren’t compressed. Both intake and exhaust valves remain closed in order to keep the mixture within the cylinder walls. Full compression is reached when the piston reaches the top of its travel (known as “top dead center”).

- COMPRESSION STROKE:

- PISTON MOVEMENT: UPWARD

- INTAKE VALVE: CLOSED

- EXHAUST VALVE: CLOSED

- ACTION: COMPRESS AIR/FUEL MIXTURE

Third Step: The Power Stroke

This stroke starts with the piston at the top of the cylinder, both valves closed, and the air/fuel mixture compressed. This is the moment when the spark plug fires, igniting the mixture and creating pressure (power) which forces the piston downward. Both valves remain closed in order to contain the pressure within the cylinder walls.

- POWER STROKE:

- PISTON MOVEMENT: DOWNWARD

- INTAKE VALVE: CLOSED

- EXHAUST VALVE: CLOSED

- ACTION: IGNITE AIR/FUEL MIXTURE

Fourth Step: The Exhaust Stroke

The piston again reverses direction and begins to move upward. The engine now needs to expel the burned remains of the fuel/air mixture. The piston’s upward movement pushes this exhaust gas upward, and the exhaust valve opens to allow it to exit the cylinder and into the exhaust manifold (and eventually, the tailpipe). The intake valve remains closed, as the engine wants all these gases to leave via the exhaust pipes.

- EXHAUST STROKE:

- PISTON MOVEMENT: UPWARD

- INTAKE VALVE: CLOSED

- EXHAUST VALVE: OPEN

- ACTION: EXPEL AIR/FUEL MIXTURE

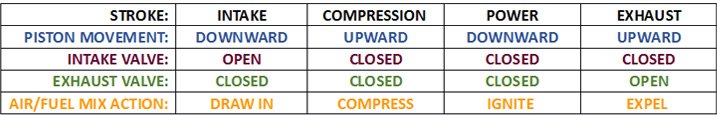

We can summarize the actions of the four strokes in this chart:

How Do Valves Know When To Open And Close?

The Purpose of Valves

An engine must have, at a minimum, one intake valve and one exhaust valve for each cylinder. In order for the 4-stroke cycle to succeed, the opening and closing of these valves is precisely controlled - synchronized with the movement of the pistons to ensure each valve performs its job exactly when needed. This precise control is known as “timing”.

Proper timing allows the intake valve to open and to let fuel-air mixture into the cylinder as the piston is moving downward during the intake stroke. And after combustion occurs, the exhaust valve opens so burned gases can be pushed out of the cylinder as the piston travels back up.

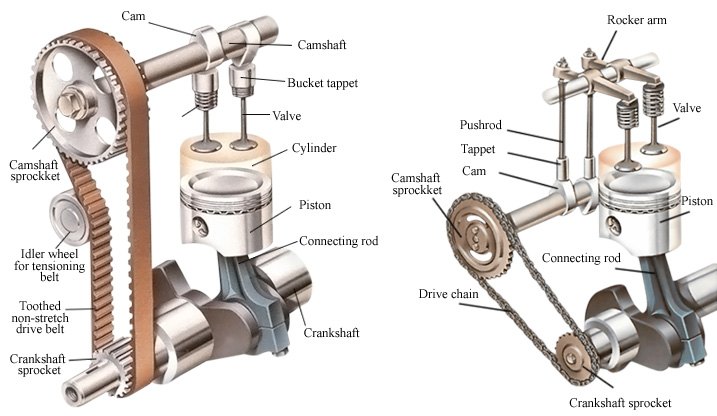

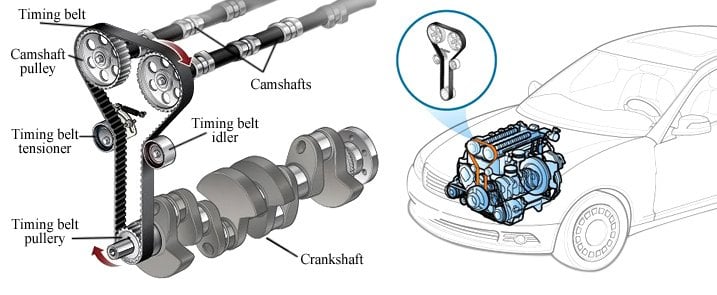

The opening and closing of all engine valves is performed by the camshaft. Each camshaft contains multiple “lobes”, which are irregularly shaped pieces located on the central shaft. As the camshaft rotates, so do these lobes which contact other components to move the valves. Valves are normally closed, and are kept closed by valve springs. The lobes must overcome spring pressure to push the valves open. As the lobe continues to rotate, the springs close the valves again. These lobes are precisely shaped and machined so that they do their part to maintain proper engine timing.

In overhead valve engines, camshafts are located in the engine block – connected to the valves by lifters, push rods, and rockers (depending on engine design). In overhead cam engines, camshafts are in the cylinder head. There is still a mechanical connection to the valves, but as the cam is closer to the valves, it’s a shorter and more direct connection.

Valves and Engine Timing

Without proper timing, valves would not open and close when they’re supposed to. The 4-stroke cycle would not function as designed. Good combustion would be difficult if not impossible, and the engine wouldn’t run – because it’s basically a giant air pump.

The synchronizing of piston and valve movement is accomplished through the mechanical linking of the crankshaft and camshaft. The pistons are connected to the crankshaft (covered in more detail below). The crankshaft is connected to the camshaft by one of 3 methods: timing gears, timing chain, or timing belt (note use of the word “timing”).

For our purposes, what is important is that the slightest rotational movement of the crankshaft causes the camshaft to rotate, which causes the valves to open or close, depending on lobe position. As long as the synchronization remains correct, the engine will operate. If, however, the timing belt or chain jumps a gear, or worse, snaps, the mechanical connection is out of sync, or ends altogether. The engine will run poorly, or will not run at all.

The Number of Valves Varies From Engine To Engine

The total number of valves in an engine will vary. Older engines have 1 intake and 1 exhaust valve per cylinder. For an 8-cylinder engine, the engine has a total of 16 valves (2 x 8). Some engines have 2 intake valves and 1 exhaust valve per cylinder. A 6-cylinder engine with such a 3-valve-per-cylinder setup would have 18 valves (3 x 6). Many modern engines feature 2 intake and 2 exhaust valves for every cylinder. A four-cylinder engine with 4 valves per cylinder would of course have a total of 16 valves (4 x 4).

As you can see from these examples, the total valve count does NOT tell you how many cylinders are in an engine.

Single- vs. Dual-Camshaft Configurations

All overhead valve engines (cam in block) have one camshaft for the engine. Overhead cam engines, with camshafts in the heads, may have one cylinder per head, or two per head. If there are two, each camshaft is dedicated to operating either the intake or exhaust valves.

Engine terminology tells us that an engine with a single camshaft PER HEAD is an “SOHC” (single overhead cam) engine. Likewise, an engine with two cams PER HEAD is referred to as a “DOHC” (dual overhead cam) engine. Be careful when counting camshafts! A DOHC V-engine with two cylinder heads has a total of FOUR camshafts (two per head).

How Does Force From The Pistons Move The Car?

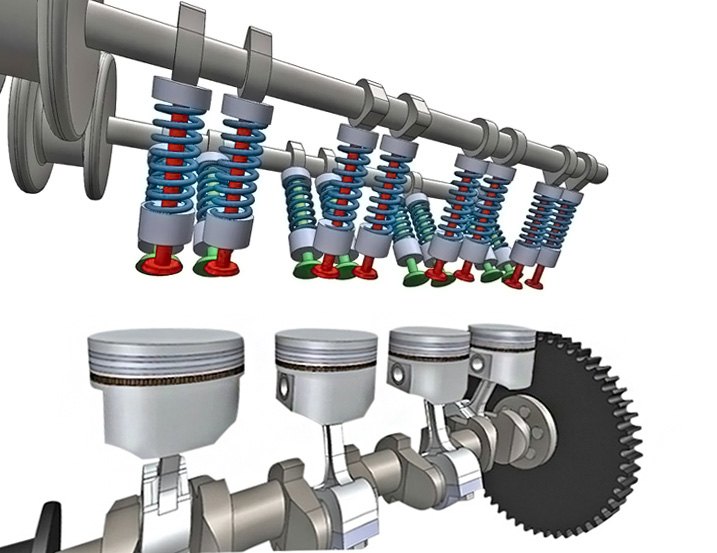

We learned that during Step 3 of the 4-stroke cycle, the ignition of the fuel/air mixture inside the cylinder provides the force to push the piston downward. Now let’s look at how the engine converts that up-and-down movement into rotary movement, which is what we need to spin the crankshaft.

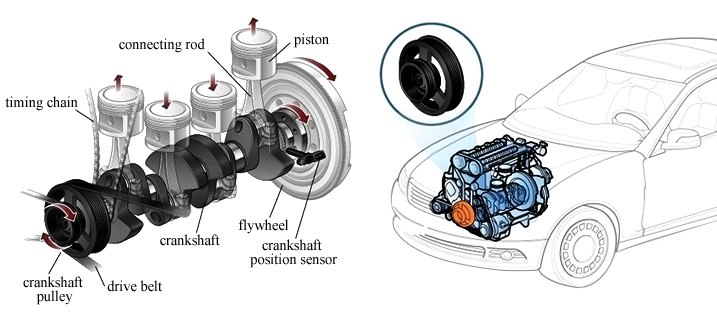

The piston is attached to a sturdy metal piece known as a connecting rod. The connecting rods can pivot at this connection point on the piston.

The lower end of the connecting rod is mounted to the crankshaft, which serves as the output shaft for the entire engine. This mounting point on the crankshaft is offset from the crankshaft’s centerline. As the connecting rod moves up and down with the piston, it rotates the crankshaft.

To help visualize this, picture the actions of a bicyclist’s legs. The up-and-down motion at the hinged knee is very similar to what is happening with the piston and the upper part of the connecting rod. But the bike rider’s lower leg and foot are moving the bike’s pedal in a circular fashion. The up and down motion of the bicyclist’s leg is converted to rotary motion at the foot, which spins the bike’s crank.

The illustration above shows the crankshaft, connecting rods, and pistons of a 4-cylinder engine. Each piston undergoes the power stroke of the 4-stroke cycle at a different time. This accomplishes several things: one, it evens out the power pulses so that the engine runs more smoothly. Second, as all the pistons are connected to each other via the crank, the power stroke of one piston is also creating the intake, compression, and exhaust strokes of the other pistons.

The regular firing of the cylinders creates the power needed to keep the crankshaft rotating with continuous torque in a steady and even fashion.

The crankshaft itself sits within the bottom end of the engine block. As the crankshaft is forced to turn from the power produced during the 4-stroke cycle, it creates twisting motion, or torque. The tail end of the crank exits the engine block at the rear, and from there, it is connected to a flywheel, transmission, and drive and axle shafts, eventually reaching the drive wheels. This is the power which propels your vehicle forward.

Now that you have a basic understanding of how a combustion engine works, you’ll be knowledgeable about what certain types of major repairs involve. And, you’ll appreciate the value of regular maintenance – especially oil changes, which keep all moving parts properly lubricated.

If you’re interested in taking things to the next level by performing an engine rebuild (or hiring someone to do it), we recommend reading our related article WHAT YOU NEED WHEN REBUILDING OR REPLACING AN ENGINE to gain an understanding of the equipment and parts that will be needed for the job. We’ve also got completely rebuilt engines that are ready for installation.

Should you have any questions about parts that you need to order, we welcome your inquiries – our knowledgeable reps are here seven days a week!