What Are Accessory Belts?

As their name suggests, accessory belts take rotational power from the engine's spinning crankshaft and transfer it to various pumps that run devices and accessories on the vehicle. Without accessory belts, your A/C compressor wouldn't be able to pressurize refrigerant that cools the cabin in summer. You'd have a hard time turning the steering wheel too, since the power steering pump wouldn't have the muscle to provide assistance. However, you wouldn't have to suffer wrestling with the steering wheel in the heat for long because your battery would quickly die without the alternator to maintain a constant charge level. But before that even happened, your engine might overheat because coolant might not be circulating (if the vehicle's water pump is externally mounted) or a belt-driven radiator fan wouldn't be spinning.

Yes, accessory belts help get a lot of essential work done. And there's no arguing that your engine and electrical system could not run without them. In this article, we'll take a look at how these important accessory belts work and wear, so you can tell when they need replacement.

Let's first take a closer look at what an accessory belt is. In our related article which details various belt types, we define an accessory belt as "An endless belt used to transmit power from a crankshaft-driven pulley to another pulley driving a fan, alternator, or other engine accessory." Think of a super-sized rubber strap, but with steel cords inside the rubber for strength and durability.

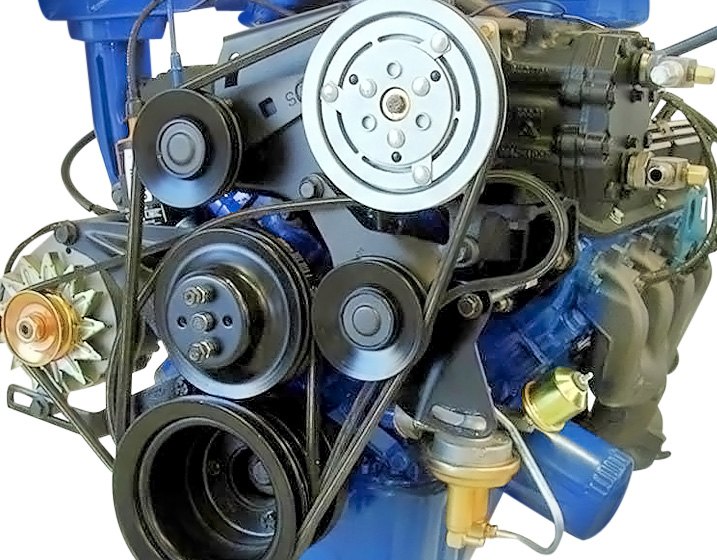

Depending on engine layout and optional accessories, belt configuration can vary. Generally, older vehicles tend to have separate, individual belts for each item on the vehicle being powered. Known as accessory drive belts, these may also be described as "fan belts", "alternator belts", "power steering belts", or other types. Such belts are typically V-shaped in cross section with the point of the V fitting into a groove in the pulley.

An improved design was the multi-grooved or ribbed V-belt. Instead of one "V", this flatter, thinner belt had multiple Vs which fit into grooves on the pulleys, making for a more secure connection between the two.

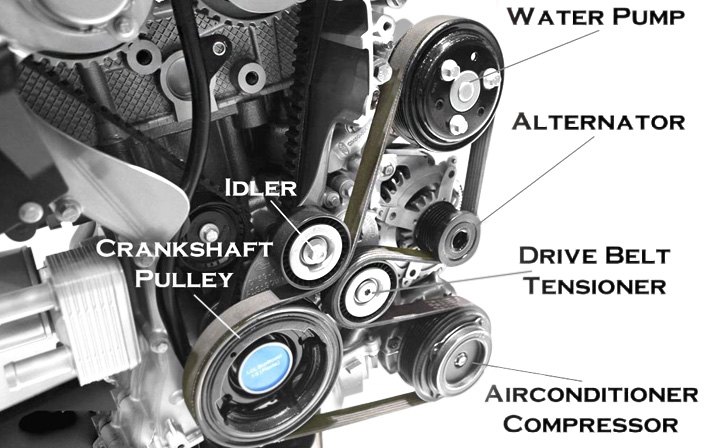

As modern engine compartments have become smaller and more crowded, packaging mechanical components into tighter and tighter spaces required a re-think of accessory belt design. A space-saving answer found on most modern cars and trucks is the serpentine accessory belt. This is simply one longer, larger belt that powers all externally-mounted accessories - not just one or two.

Unlike individual belts, tension on a serpentine belt usually comes from a tensioner pulley that's spring loaded to provide constant pressure so that the belt stays tight. In order to help route the belt so that it reaches all the accessories, neutral idler pulley wheels create bends and u-turns exactly where they're needed. On older vehicles, some belts may need periodic tightening manually.

Factory Recommendations

Until the turn of the millennium, automakers traditionally recommended replacing accessory belts as a maintenance "wear" item around 60,000 miles. After that point, the creation of a synthetic rubber compound known as ethylene propylene diene monomer (EPDM) allowed the useable lifespan of accessory belts to jump dramatically. Because these belts can go 100,000 to 150,000 miles and last up to 10 years, scheduled maintenance intervals were revised from recommended replacement to a mere "inspect condition of". Depending on the automaker, belt inspection is advised every 10k or 20k miles, starting anywhere between 40,000 and 100,000 miles.

With such a range of recommendations, it's not always easy to be sure exactly what's best for your vehicle. Maybe your owner's manual says belts will be fine until 100,000 miles, but you don't entirely trust that prediction. Or maybe you purchased an older used car with some miles on it, and there's no way to be sure when or if the belts were ever replaced. And if the belt(s) was replaced, is it a newer one that will last longer than the factory original?

Signs Of Belt Wear

As rubber compounds in all accessory belts age, they'll eventually start to crack, fray at the edges, become hardened and glazed, crumble - and ultimately break. Here are some telltale signs your belts are wearing out.

Cracks and Missing Chunks

Older belt types are more prone to losing big chunks than newer EPDM ones, but it can occur nonetheless. Most belts can still function just fine if a few bits are missing, but when a lot of chunks are gone, that's a clear sign the belt is reaching the end of its lifespan.

Starting with visible cracks, small ones along the top surface of the belt aren't a big deal if they're not deep. A proven rule of thumb dictates that if a crack reaches more than halfway through the belt, the risk of the belt breaking increases exponentially - so replace it immediately! Make sure to inspect both sides of the belt, not just the smooth surface on top.

On the underside of the belt that contacts the pulley wheels, cracks on 3 or more ribs next to each other in any 1-inch section indicate a worn belt. Additionally, 4+ cracks along a 1-inch span of a single rib indicate replacement is needed.

Squealing Noises

Another major sign of belt wear is an audible squealing noise that indicates the belt is slipping. Usually this occurs during the first few seconds after the engine is started, then the squealing will go away.

A belt that slips regularly will also have polished edges and glazed belt grooves - replacement should be done as soon as possible. A belt will also squeal if it gets significantly wet from any kind of fluid spilling onto it, so check to see if any coolant or power steering fluid leaks are present. Address these, and replace the belt if it's become contaminated from regular contact. If water has gotten onto the belt due to rainwater collecting on the pulley wheels, that's nothing to worry about.

Low Battery or Other Warning Lights

If a belt which runs the alternator slips significantly enough, electrical output from the alternator may be reduced and uneven. As a result, the battery won't be able to maintain a full charge - causing a reduced voltage condition throughout the vehicle. Electronics and on-board computers can literally become confused during such instances, resulting in erratic and unpredictable performance of everything from power windows to diagnostics. A low battery warning light will be displayed - but other warning lights may appear for phantom problems that don't exist.

Tensioners & Pulley Wheels

A quick, repeated chirp from the belt is usually more indicative of a belt pulley wheel that's misaligned (look for frayed edges on the belt as well).

We also strongly encourage replacing accessory belt tensioners and pulley wheels if they're causing noticeable problems. Additionally, check the condition of any idler pulley wheels put in place to determine the belt's path. Pulley wheels contain bearings which wear gradually over time, and past a certain wear point they can no longer keep the pulley supported in a flush and level position. Bad bearings will produce a grinding noise, and a weak tensioner spring will produce a wobbling type of vibration. Severe cracks in the belt can result from a bad tensioner.

Generally, a tensioner in good condition will create a smooth-running belt with only slight vibrations and minimal movement of the arm piece (approximately 1/32nd of an inch). A tensioner arm that allows a jerky wobbling motion of the belt or shifts more than 1/4th of an inch needs replacement. Also check for excessive side-to-side play of tensioner pulley wheels. Rotate them also to see if they spin easily, or if roughness can be felt as they turn. Anything that isn't right should be replaced. Swapping on a new belt without replacing the tensioner would only would be a waste of time here, since the belt will have to be removed again for a new tensioner.

Loss of Material

All belts, particularly serpentine ones, will suffer loss of the rubber material from their edges and grooves during normal wear. This wear can be accelerated by a misaligned pulley wheel. Gradually, the rubber that has worn off tends to collect in between the grooves, dulling the sharp edges and creating a situation where the belt cannot be held as tightly by the tensioner. Check closely for this.

Opportune Times To Replace An Accessory Belt

Naturally, the removal and replacement of any items that a belt travels over means the belt itself must also be removed first in order gain access. So when it's time to install a new water pump, alternator, power steering pump, or A/C compressor, this is an ideal time to inspect applicable belts and pulleys. We suggest that unless the belt is already in excellent or good condition, it makes the most sense to also replace the belts during reassembly.

No two engines are exactly the same in layout and placement. So it's possible a specific repair on one automaker's engine requires belt removal, while the same repair on another make does not.

Replacing a timing belt and/or internally mounted water pump requires the removal of the front engine cover for access. Before this can be done, however, all accessory belts on the front of the engine must be removed also. We've said before that you should not confuse the timing belt with the accessory belts; at the same time, this becomes another opportunity to replace the auxiliary belts while they're off the car.

Serious engine repairs that require teardown (cylinder head gasket replacement, or front engine seals, to provide two examples) are also a common-sense opportunity to install new accessory belts upon reassembly. After all, there's no extra labor if the belts have to come off anyway.

If you are so fortunate that none of these expenditures are necessary after a long period of time (let's say 7-10 years), a pre-emptive replacement of all the accessory belts will help avoid that dreaded breakdown when it's most inconvenient, such as the start of a vacation. Time is as much a factor as mileage when it comes to the wear of a rubber item.

Now you are armed with the knowledge to recognize when an accessory belt or serpentine belt is at risk of breaking. Considering the inconvenience of getting stranded when that happens, or the safety issues that can result when you suddenly lose power steering assist, delaying replacement of worn belts, pulley wheels, or tensioners is skirting disaster.

If you're not sure which belts or other components would match your car or truck, just enter its year, make, and model details in our "Select Vehicle" box along the top of the screen. Our system will then present only those items which are an exact, vehicle-specific fit. And if you have further questions, we also welcome any product questions you may have by phone seven days a week.