An intake manifold is an integrated assembly that sits atop the engine, consisting of a series of tubes which distribute fresh outside air to each and every cylinder. On V-shaped engine blocks, an intake manifold typically sits between the two cylinder banks while inline engines may feature a manifold to the side of the cylinder head. Intake manifolds serve as a mounting point for carburetors, throttle body assemblies, fuel injectors, thermostats, and more depending on vehicle manufacturer engineering preferences.

Intake manifolds may also serve to route coolant through dedicated channels in order to remove heat from the engine. Because of their location and functionality, intake manifold assemblies are under constant stress from engine vacuum pressure as well as direct heat from coolant, cylinder combustion gasses, and the cylinder heads to which they are mounted.

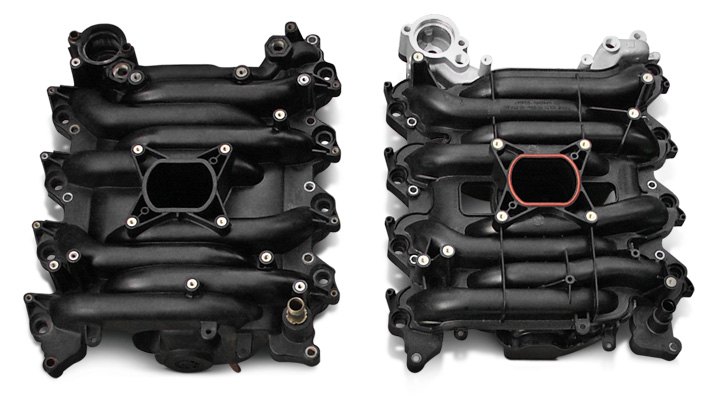

Up until the 1990s, most intake manifold assemblies were made from cast iron when lower cost was a predominant factor, or from aluminum when lighter weight was judged more important for performance reasons. Intake manifolds molded from plastic began to gain popularity during that decade because they offered both lower weight and cost. They were installed as original equipment when automakers figured out how to manufacture them in a form that was durable enough to survive initial testing. In this article, we'll discuss some flaws of early plastic intake manifolds, and we'll discuss how those issues have been addressed in the quality replacement units which can be purchased today.

Early Plastic Intake Manifolds Had Some Flawed Designs

What was not originally factored in by car company engineers was extended real-world use. Early designs were biased toward keeping the overall manufacturing costs as low as possible, so these original plastic intake manifolds were not overbuilt. Vehicle manufacturers may not have intentionally cut corners, but little was known at that point how well plastic intake manifolds would really hold up over time or what might cause them to fail.

Some of the first designs ended up being flawed, and original plastic intake manifolds used on 1990s General Motors 3.8-liter V6s, Ford 4.6-liter V8s, and Chrysler 4.7-liter V8s are among the more common examples of designs prone to early failure. For these engines, check out the Dorman Intake Manifold and ATP Intake Manifold. The Mopar Intake Manifold is also available for a wide variety of engines found in Chrysler, Dodge, Jeep, and Plymouth vehicles originally equipped with plastic intake manifolds.

We’ve got the AC Delco GM Original Equipment Intake Manifold covering all GM brands from 1993 on (including Hummer, Saab, Saturn, and select Suzuki vehicles). And if you’ve got a European or Asian import, take a look at the Genuine Intake Manifold.

Dissimilar materials such as plastic, aluminum, and iron all have different expansion and contraction rates as they change temperature, so gaskets that provide a seal between an intake manifold and a metal cylinder head must be flexible and durable enough to withstand serious pulling and twisting forces. Early ones were not, and leaks resulted along with warpage under intense heat that eventually led to cracks.

Coolant which is old and deteriorated can be corrosive to plastic, and walls of the tubes carrying anti-freeze inside the manifold can be gradually eaten away. Early designs didn't account for this, eventually leaking coolant directly into the cylinders when tube walls gave out. While a little coolant causes rough running, too much coolant can cause an engine to seize up completely because water cannot be compressed.

Like any oil-based product, plastic can become dried out and brittle with the passage of time - especially when subjected to intense heat. Without proper reinforcement, fittings on the outside of early manifolds for exhaust gas recirculation (EGR) valves, heater hoses, thermostats, temperature sensors, and other items were prone to cracking off completely. One manufacturer even mounted alternator supports directly to their plastic manifolds, and that extra weight eventually led to large scale cracks and failure.

Today's Intake Manifolds Have Improved Plastic Composites And Designs

More and more automakers are switching to plastic intake manifolds. After decades of testing and studying common failure points, optimum blends of plastic with 35% fiberglass or related glass elements have been perfected to enhance both strength and elasticity. Today's plastic intake manifolds are more than just mere plastic.

Greater strength from engineered compounds resists cracks under pressure where it's most needed, and greater elasticity yields the ability to stretch and snap back - preventing permanent warpage which causes leaks. Failure rates of quality plastic intake manifolds manufactured in recent years have dropped significantly, and high reliability over long-term use makes them a smart purchase.

Thicker construction in critical areas prevents erosion from dirty coolant, and the addition of aluminum reinforcements provides increased load-bearing capacity for external fittings and components. Plastic compounds dissipate heat better than metal, so air flowing through intake tubes remains cooler to aid combustion.

Sound-deadening acoustic qualities of newer compounds have been improved, making them as good as their metal counterparts in eliminating raucous and unwanted engine noises. Silicone-based gaskets allow better flex between dissimilar materials, and they help eliminate corrosion and vibrations.

If you're considering purchasing a plastic intake manifold, finding one with these improvements will be your best bet to insure that you're chosen the best part. If you’ve got any questions or need help during your selection, give us a call seven days a week – we’ll be glad to help!