The springs in your vehicle probably aren't something you think about until there's a problem or you've decided to upgrade suspension parts in the interest of sportier handling. But what specifically do springs do?

In short, they play a major role in the safe handling and ride comfort of your vehicle. Not only do they keep a vehicle at a designated standing height, they provide recoil necessary to bounce back after suspension components move up and down over uneven road surfaces. By themselves, springs will continue to bounce up and down for a long time unless a motion damper such as a shock absorber is present to keep things stable. Springs can be soft and extremely bouncy, or they can be stiffer and less bounce-prone.

When it comes to simple, basic springs made of metal that don't require electricity, hydraulics, or air pressure to function, there are three main types. In this article, we'll examine those three types to help you understand how each one functions, and how they differ from one another.

We'll also guide you to the appropriate sections of our website if you're in need of original equipment style replacement suspension components or performance upgrades that yield changes in handling or ride height. Because the types of springs fitted as original equipment on the front of many vehicles differ from those fitted on the rear, our website Product Options field will automatically provide guidance in that category for any make and model.

Coil Springs

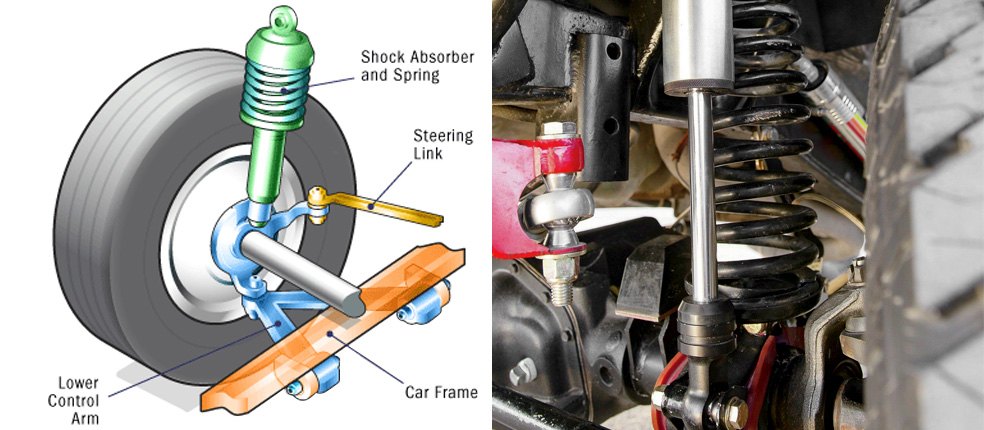

Coil springs are made from hardened and tempered steel, wound in a spiral formation. Most modern passenger cars built in the last few decades feature coil springs at all four wheels, and an increasing number of pickups and SUVs are now equipped with them in the front as well as the rear. On MacPherson type struts, a coil spring is mounted around a shock absorber - both of which are attached to the strut itself. On other vehicles without struts, coil springs and shock absorbers are mounted separately.

What Is Coil Spring Rate?

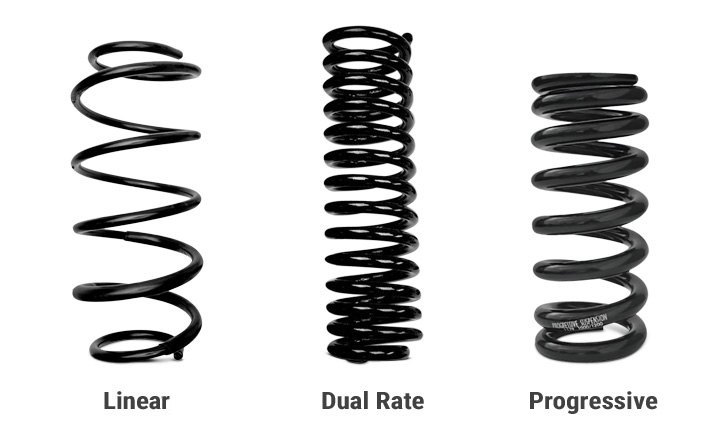

Coil springs can be firm, soft, or have a spring rate that varies. As a pound-per-square-inch measurement, spring rate is the force required to compress a coil spring 1 inch. The higher the per-inch spring rate, the stiffer the spring. This measurement is also used to describe whether a spring has the same rate of compression at all points during its travel ("linear"), gets progressively stiffer the more it compresses ("progressive"), or is specially configured to change characteristics abruptly ("dual rate").

Advantages

Coil spring suspensions allow the most flexibility when it comes to variable rate characteristics. For trucks, variable rate coil springs allow a comfortable ride when the vehicle is unloaded. As weight is added, the spring rate becomes stiffer to increase stability without the ill effects of bouncing, and it prevents the ride height from dropping significantly.

For performance-oriented cars with a low ride height, variable rate springs allow better absorption of bumps during normal street use, then become stiffer around turns to reduce body roll during aggressive driving. Coil springs can also allow for a greater amount of up and down wheel travel, which is a huge advantage on rutted and rocky off-road trails.

Disadvantages

Coil springs aren't as well suited to carrying heavy loads as leaf springs are. With coil springs, vehicle weight is concentrated onto a smaller surface area of the vehicle frame, while leaf springs spread a load out more evenly. To save overall weight on cars that keep getting heavier with additional standard and optional equipment, some manufacturers have taken to making coil springs lighter and thinner.

Unfortunately, this makes them more subject to cracking and breaking under pressure - especially if corrosion sets in. What would be non-threatening surface rust on more robust springs can cause thinner ones to be significantly compromised. Some vehicle manufacturers have applied durable surface coatings around the springs - both for corrosion resistance and to prevent any broken shards from flying loose and puncturing tires.

How to Tell When Coil Springs are Worn

As coil springs age, they naturally lose their resilience and start to sag, causing ride height to drop. So if your vehicle droops at the front or rear, those springs are probably worn out. If there's a noticeable difference in ride height between the left and right side of the vehicle, a coil spring may be broken. Either of these problems will become especially obvious when even a small amount of weight is added - such as one or two passengers in the rear seat. Broken coil springs also tend to generate some kind of noise as things shift.

Because coil springs are often fitted to vehicles with more sophisticated independent, multi-link suspension systems, improper ride height has more of a negative effect on wheel alignment and tire wear. If you think your ride height may be sagging, vehicle manufacturers typically list ride height specifications in owner manuals and on the internet. It's easy to make a measurement yourself for comparison purposes. When you think it's time to replace those springs, we've got a wide selection of springs and related items.

If you prefer OEM style replacement coil springs, we've got the springs themselves as well as spring seats (top and bottom rubber insulators), upper and lower mounting brackets, and adjusters/shims for when you need additional support or adjustment to the original mounting position.

If you're looking to modify your suspension, we've got coil springs that enhance performance. You may also find our selection of suspension lift kits, spacers, and leveling kits (these raise the front more than the rear) interesting if you've got a 4x4 you want to raise. And if you appreciate manual adjustability for ride height and stiffness, take a look at our individual springs for coilovers. We've also got spring seat isolators along with various hardware pieces.

Leaf Springs

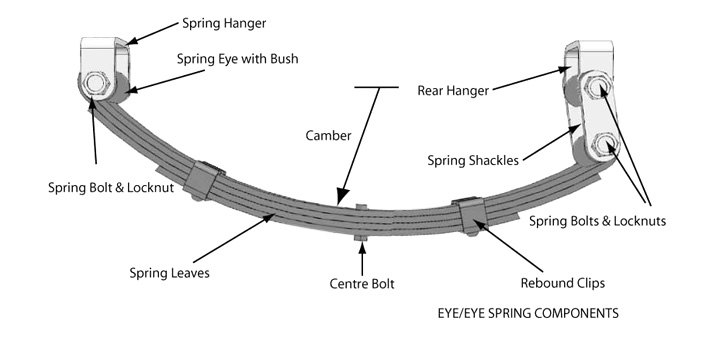

Leaf springs are literally older than the automobile itself, having been in use since the earliest horse-driven carriages traveled the countryside. Very simple in layout, a leaf spring setup is composed of one or more lengths of arched spring steel.

Each arched steel piece is known as a leaf, and one or more leaves may be stacked on top of each other and mounted above or below a solid (non-independent) axle beam assembly. Because they are bolted to the axle, leaf springs support the weight of the vehicle and serve to secure the axle to the vehicle frame.

Mono Leaf vs. Multi Leaf Springs

- A single leaf setup typically found on small lightweight cars is known as a "mono leaf" spring.

- Multiple leaves stacked on top of each other are known as "multi leaf" springs.

Both types of setups have a "main leaf" that features curved ends with round bushings built into them known as eyes. Since a mono leaf spring is comprised of only one leaf, that leaf serves as the main attachment leaf.

On multi-leaf setups where additional leaves become progressively shorter in length, the longest leaf serves as the main attachment leaf. While the front eye of the main leaf is typically mounted directly to the vehicle frame, shackles are often used at the rear to allow flex as the leaf springs elongate under compression. One end of the shackle is attached to the vehicle frame, the other to the rear eye.

Mono leaves were developed by automakers who were trying to create a better ride for lightweight passenger cars. Because these springs are thickest at their center and thinnest at their end points, a variable spring rate is produced which yields a soft, flexible ride that stiffens up for better control around corners.

"Split" mono leaf springs consist of two partial leaves that are bound together in the center where they overlap for approximately 6 to 12 inches. The overlapping creates a stiffer spring than a standard mono leaf without adding much weight. Split mono leaves are popular choices for older muscle cars used in drag racing, so you won't find them as standard equipment.

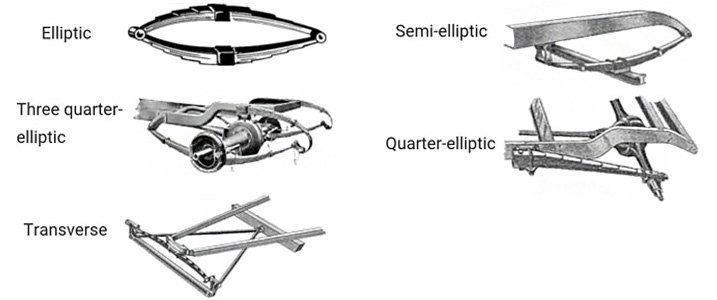

Because leaf springs are best suited to heavy vehicles that carry large payloads, they're most commonly found on solid axles of pickups, SUVs, and larger trucks not equipped with air suspension. On these vehicles as well as older body-on-frame cars, leaf springs are mounted longitudinally from front-to-rear alongside frame rails. On other occasions, they have been mounted transversely from left-to-right on various front and rear suspensions.

Advantages

- Leaf springs are the simplest setup, with the fewest number of moving parts to wear out.

- Unlike coil springs, leaves serve to keep the rear axle in place so the need for complex suspension linkages is eliminated.

- When a lot of weight is being carried, leaf springs spread the load out more evenly across the vehicle's chassis than coil or torsion bar springs.

- The friction produced between multiple leaves as they slide helps damp the natural up-down rebounding effect of springs - making the ride steadier and reducing the work that shock absorbers must do.

Disadvantages

When leaf springs are bolted directly to rear axles, torque generated during hard acceleration or braking can cause axle wind-up which creates vibration, rear-end squat, and nose-diving. This mounting also requires leaves to have a stiffer spring rate - reducing ride comfort levels that softer springs would provide.

This setup offers very little adjustability and isn't very suitable for suspension tuning. Because of the way the leaves are attached, adjusting them is only possible through changing their material composition in order to alter their strength and flexibility characteristics. For example, the Chevy Corvette used fiber reinforced plastic leaf springs.

How To Tell When Leaf Springs Are Worn

When worn leaf springs lose their resilience, they begin to sag. Vehicle ride height drops as a direct result, so it's a good idea to measure ride height yourself and compare it to the manufacturer's specifications if you feel there's a problem. Along with lowered ride height and lost spring bounce come complications such as bottoming out much easier over bumps - something that's harmful to suspension components and possibly to your payload.

When leaf springs become worn, the leaves can develop visible cracks and corrosion. Sometimes if corrosion and wear are bad enough, a leaf can break in two - with a section of it falling off the vehicle entirely. When rubber bushings in spring eyes and shackles dry up and crumble, cushioning is lost and ride harshness significantly increases.

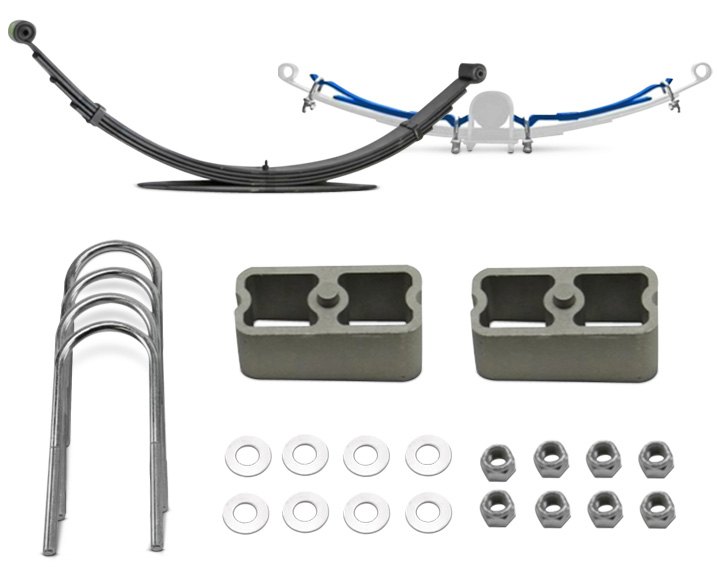

Want to see what your options are for replacement leaf springs? For OEM style leaf springs replacement needs, we’ve got shackles, bump stops, spacers/shims, and assorted hardware pieces. These will restore your ride quality to factory new specifications.

If you're interested in modifying your factory leaf spring setup, see our page for performance-enhancing leaf springs. There, you'll find lowering kits to drop ride height as well as add-a-leaf kits and leaf spring blocks for raising it. There are also shackles and spring pads along with mounts, bushings, and other hardware.

Vehicles You'll Typically Find Leaf Springs On

Leaf spring suspensions were almost universally used on the rear axle of rear-wheel-drive (RWD) American passenger cars from the 1930s through the 1970s. The Chrysler Corporation continued to use them through the 1980s. When carmakers began to switch to front-wheel-drive platforms, rear leaf springs were tossed in favor of coil springs.

Most traditional pickup trucks used leaf springs in the rear AND front suspensions through the 1960s, as these vehicles had non-independent suspensions at all four corners. As pickups matured and gained independent front suspension, they switched to coils or torsion bars in the front. Many pickup trucks and vans continue with rear leaf springs today.

Torsion Bars

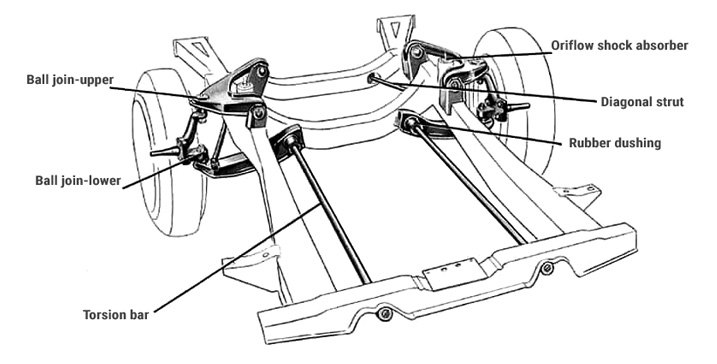

How do torsion bars work? While leaf springs flatten out and coils compress when vertical loads are applied, the damping action of torsion bars is achieved through twisting. They are basically steel tubes mounted to the chassis at one end and to control arms at the other. The chassis end remains stationary, while the control arm end is designed to twist along its axis as the wheel moves up and down.

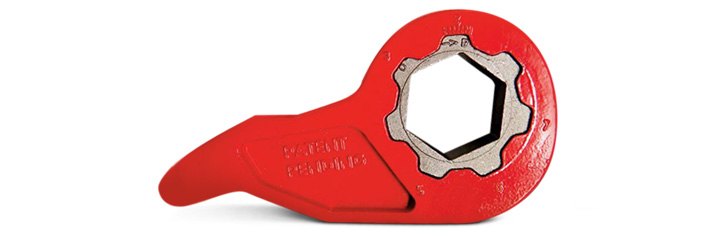

Torsion bars are typically mounted longitudinally, with greater length offering more wheel travel on four-wheel-drive vehicles. The attachment ends of torsion bars are commonly hex-shaped or splined. At the fixed end of the bar, there is a "key" – an anchor point, a lever that keeps the bar attached to the frame and holds it at the required height. Its position can be adjusted to raise or lower ride height.

On this type of suspension, spring rates depend on the length, thickness, and diameter of torsion bars, as well as the raw materials they are manufactured from.

Advantages

- It is relatively easy to adjust the ride height. What's more, performing a torsion key lift when the springs show the first signs of wear will increase their service life, all while keeping ride height at the proper level without alignment issues and abnormal tire wear.

- More compact design than other forms of suspension.

- Little to no maintenance.

Disadvantages

Relatively low mounting points underneath the vehicle leave torsion bars more prone to damage from rocks and other obstacles.

How To Tell When Torsion Bar Springs Are Worn

The first sign that torsion bar springs are getting worn down is sagging. They can also be the culprit behind a harsher ride because the range of twist reduces over time. Can torsion bars make noise? They sure can! This happens when rubber cross member mounts dry out and cause metal-on-metal squeaking.

If you're ready to replace your OEM style replacement torsion bars, we've also got keys, adjuster pieces, vehicle mounting brackets, and various hardware pieces.

If you prefer to raise or lower your ride height and improve handling, we've got performance-enhancing torsion bars along with individual components such as keys, polyurethane bushings, and related hardware.

Well-Known Vehicles That Have Used Torsion Springs

Torsion springs probably saw the most widespread use on all classic Volkswagen Beetles, Karmann Ghias, Microbuses, and other rear-engine air-cooled derivatives of those models. They were also widely used by Chrysler on all rear-wheel-drive vehicles from 1957 through 1989, by GM on front-wheel-drive Olds Toronados, Cadillac Eldorados, and Buick Rivieras through 1985, Porsche 911s from 1963-1989, Porsche 924/944/968 models from 1977-1995, Jaguar E-Types from 1961-1974, early Acura Integras, and older out-of-production makes such as Hudsons and Packards.

Whether your ride uses coils, leaves, or torsion bars (or some combination of these) replacing worn springs will bring noticeable "quality-of-life" improvements that you'll feel in your hands and in the seat of your pants - every minute behind the wheel of your car or truck. New springs will bring back its handling as engineers intended it, without harshness over uneven surfaces, and it will no longer scrape over speed bumps when passengers are along for the ride.

If performance handling is your focus, upgrading your springs will give you the full value out of more aggressive wheels, tires, shocks, and other suspension components. If you're replacing other suspension components anyway, it's penny-wise and pound-foolish to keep your worn-out OE springs in place.

To help guide you through the selection of springs we offer, we've set up corresponding sections of our website to provide you with all the choices that will fit your vehicle. It's possible to enter specific make, model, and year in drop down boxes before beginning your search. Or, input vehicle information after entering an individual page. Once those new springs are installed, enjoy the ride!

FAQ

How to make a torsion bar adjustment?

Making small adjustments to ride height on a vehicle equipped with torsion bars doesn't require replacing any components. However, if you want a higher lift than your stock setup can offer, swapping your factory keys for upgraded aftermarket products is an option. The shape of aftermarket torsion keys is slightly tweaked to allow raising the suspension higher without compromising ride quality, and the materials and manufacturing methods used are often more advanced than stock for greater strength.

One way or another, the key can be turned to the raised or lowered position with a few turns of a wrench. Make sure not to overrotate the bars to avoid a harsh ride and eventual breakage. You'll need sturdy jack stands and a special torsion bar unloading tool. Once the job is complete, it's a good idea to have an alignment performed.

How much can you lift a truck with torsion bars?

Depending on the truck, cranking up your stock keys can bring around 1.5". Aftermarket torsion keys provide "re-indexing" to achieve up to 2.5" – 3" of lift without making the ride too harsh – again, depending on the model.

Why do coil springs break?

- Metal fatigue. Steel coils get weaker over time and can wear out and eventually break faster than expected due to frequent overloading and driving on rough roads.

- Corrosion. Coil springs break when severely rusted. Vehicles driven near the ocean, in areas with cold winters, especially those where salt is used on the roads to combat the snow and ice, are more susceptible to corrosion. Although many coil springs feature anti-rust coatings, continuous compression cycles and exposure to flying stones and debris eventually damage the protective layer.

- Faulty shocks & struts. Leaky shock absorbers pose excessive strain on springs and eventually damage them.

- Improper manufacturing & defects. Some manufacturers make the wire thinner to reduce weight, but this also makes springs more prone to breakage over time – especially when rust develops. Impurities in spring material, design flaws, and manufacturing errors can shorten the spring's service life.

What happens if you have a broken coil spring?

This kind of breakage places greater strain on shocks or struts, affects wheel alignment, and accelerates tire wear. The impact of hitting a pothole or bump can displace a broken spring and result in damage to nearby parts, including suspension components, tires, and brake lines.

How long do leaf springs last?

The average service life of leaf springs is nearly 200,000 miles. Their lifespan depends on how you use your vehicle, how often you haul heavy loads, and where you drive (road conditions, regions where rust is a known problem, etc.)

Will leaf springs lift my truck?

If you want to increase the ride height, you can add more leaves that will strengthen your existing setup, or upgrade to a pack of bigger leaves that will replace your existing leaf springs.