In this Part 2 of our suspension components guide (Part 1 was springs & shocks), we give an overview of the differences between "replacement" (OE factory style) and "performance" (aftermarket) control arms along with their related bushings. We'll discuss how control arms are applied to the various styles of springs and shocks that exist, and we'll note how replacement and performance versions of each component differ.

If your desire is to restore the original comfort of a new-car ride, replacement control arms, bushings, and ball joints are your best bet. If your tastes lean towards tighter handling, ride height changes, or off-roading, performance components can make a noticeable difference. In many cases, you can select quality OE style components (and many performance ones) from us and still spend less money than you would for similar parts at the dealer level.

The majority of replacement and performance control arms we sell come with bushings (and ball joints) already pressed into place - so they're ready for easy installation when you receive them. However, since bushings typically wear out first, we offer these components individually with a wide range of choices (see sections further below).

Control Arms

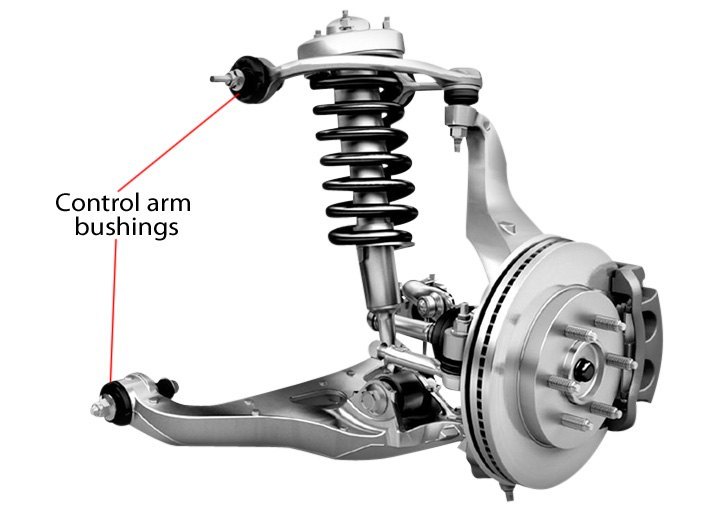

Often described as "A-arms" or "wishbones" when used with independent suspensions, control arms are beefy metal pieces that connect a vehicle's frame (if body-on-frame) or unibody to a spindle or hub, to which a wheel/tire assembly is attached.

Pivot points at the control arm attachments allow for suspension travel as the wheels and tires move up and down. As a wheel travels over bumps, control arms pivot up and down in their respective locations in order to reduce shock transferred to the rest of the automobile.

Sometimes, certain types of control arms referred to as "trailing arms". These are a type of control arm (mounted fore-aft) commonly used with solid axle rear suspensions. Independent rear suspensions may also have trailing arms, lateral links, A-arms or other types.

Control arms can be made of stamped steel, cast iron or aluminum, to achieve either higher strength or lighter weight. The metal control arms themselves are generally very durable components; the common wear areas are the bushings and ball joints. However, there are conditions when entire control arms need to be replaced. For example, steel control arms are susceptible to rust which can weaken the arm and cause it to fail. Control arms may crack, especially if suspension travel has been modified or if the vehicle is abused. No matter what the material, all control arms are subject to bending or distortion from hard curb impacts and other collisions - even improper hookup to a tow truck.

Even the slightest deformation of a control arm can cause pulling, abnormal handling, and irregular tire wear. Bent control arms make it impossible to perform a wheel alignment, because angles cannot be adjusted within specification. Unfortunately, such damage may not be obvious until an old control arm is compared side-by-side to a new one.

Control arm replacement may also be necessary if it becomes impossible to service bushings or ball joints individually. However, even when bushings and ball joints can be replaced individually using drivers and presses to pop things apart or together, installing a complete control arm with these pieces already in place may save a great deal of labor time (and money).

Total control arm count varies of course from vehicle to vehicle depending on suspension design. The traditional front suspension used to consist of upper and lower control arms on each side, for a total of four control arms in the front. Many if not most newer cars have adopted struts, which only use a lower control arm, one on each side.

In the rear, because of axle placement, it is quite common to find only lower control arms, for a total of two, one on each side. That's not to say that there are some vehicles which use both upper and lower control arms in the rear, much like a front suspension.

When you plug in your particular year, make, and model vehicle into our website, the search results will inform you whether your car or truck has upper and/or lower control arms.

Control Arms - Replacement

As we mentioned in the introduction, control arms we offer in our Replacement control arms section will eliminate the frustrations of worn ones by restoring your ride quality to factory original specifications. In other words, these will match overall OE dimensions, thicknesses, strength, and on-the-road performance for your specific year, make, and model vehicle. Modifications will not be required for installation.

In most cases, replacement control arms are available with new rubber bushings and ball joints already pressed into place - eliminating the need for specialized tools or paying a professional shop to perform the operation.

While they're being replaced, it makes sense to install new nuts, bolts, mounts, brackets, and other related hardware. Sometimes these items are included with the control arms - but are available individually should you need them. Check boxes in the Refine Search menu on left side of the screen will help you find exactly what you seek.

For a wide range of makes and models from decades ago through today, you'll find a great selection with the AC Delco Advantage Control Arms, Beck Arnley Control Arms, Genuine Control Arms, Mopar Control Arms, and Motorcraft Suspension Control Arms.

For more specialized vehicle applications, we've got the Goodmark Control Arms (1960s-70s Ford/GM/Chrysler cars), Dorman Control Arms with Ball Joints (classic & modern domestic and import vehicles), Crown Suspension Control Arms (older & newer Jeeps), and URO Parts Control Arms (various Mercedes/BMW/Saab models 1973-today) just to name a few.

To see exact product matches for your own vehicle, be sure to enter the year, make, and model in the search box along the top of the screen.

Control Arms - Performance (On Pavement)

In our Performance Control Arms section, you'll find control arms that are lighter in weight than OE replacement ones, and you'll find control arms with beefier construction designed to endure harder pounding during off-roading. Both flavors usually include polyurethane bushings which create less squish than rubber during hard use (see below for more details on these bushings). Many of our rear control arms and links are adjustable, so critical dimensions like pinion angle and rear wheel alignment can be dialed in.

Classic muscle cars with solid rear axles are usually equipped with stamped steel rear control arms that can flex out of shape when high amounts of horsepower are put to a set of big, sticky tires. To correct this, we've got beefier control arms with the increased strength necessary to keep the rear axle in proper position without deflecting. This ensures that power makes it to the road better thanks to higher level of traction.

Besides inadequate strength, many OE control arms are simply the wrong shape for wider wheels and tires needed for track racing and on-road performance driving. Often, such tires will rub against factory control arms because proper clearance no longer exists in the wheel wells. Sometimes control arms must be relocated to optimize alignment angles, especially when ride height is changed. In other cases, particularly racing, the control arm mounting points require strengthening.

Altered ride heights generally require different suspension alignment angles for precise handling and control, and stock control arms may not have the range of adjustment necessary.

Our performance control arms provide the clearance and geometry to solve these issues. Some have enhanced adjustment features built right in to the control arm, and a number of arms have the optimal caster and camber needed for improved stability and steering response already designed into the control arm. Plus, we offer a comprehensive selection of custom relocation brackets, mounts, and braces.

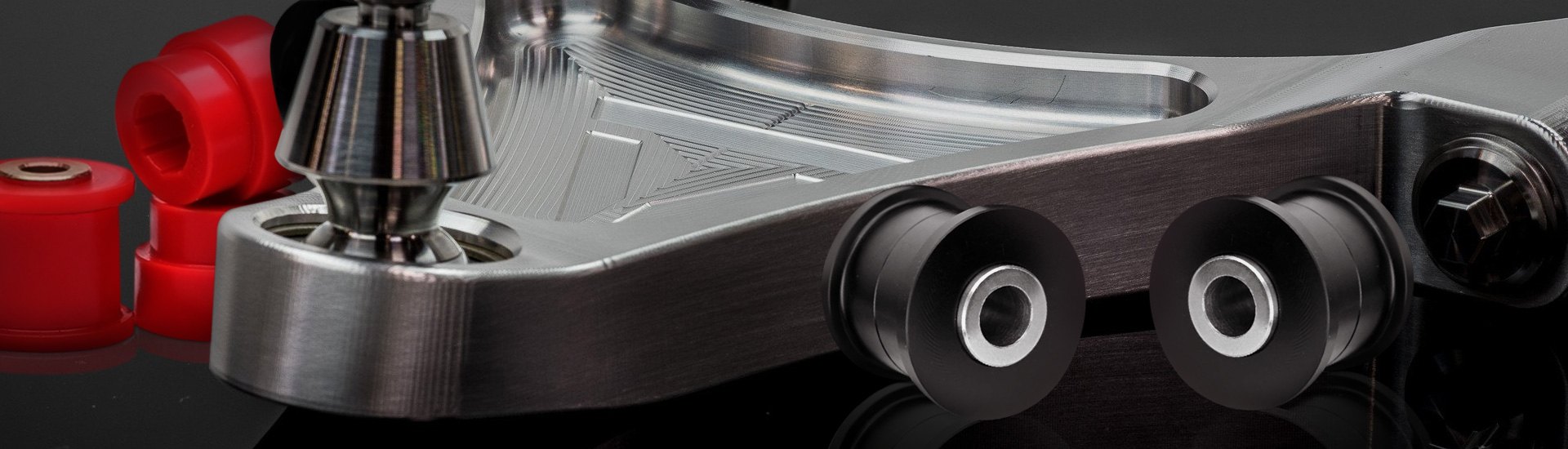

On-the-road performance control arms include the Hotchkis Tubular Control Arms, Agency Power aluminum Control Arms, Icon Billet Aluminum Uniball Upper Control Arm Kit, Skunk 2 Control Arms, and Megan Racing Control Arms among others.

Control Arms - Performance (Off-Roading)

OE suspension upper and lower A-arms can reveal their weaknesses when 4x4s are lifted and driven aggressively off-road. These control arms can flex under severe duty use - resulting in poor handling, loss of steering control, and even breakage. To allow greater flexibility, performance control arms typically come standard with low-friction ball joints and performance polyurethane or Delrin bushings installed.

If you're looking to upgrade your 4x4 for the trails, the Zone Offroad Heavy Duty Control Arm Kit, ARB OME Control Arms, Pro Comp Control Arms, and Dirt King Fabrication Control Arms are just a few of the great examples we offer. To see only products that fit your car or truck, enter its year, make, and model in the search box at the top of the screen.

Control Arm Bushings:

While control arms themselves pivot up and down at various angles in order to soak up road irregularities and reduce severity of bumps, it's a fact that noise, vibration, and harshness levels inside the vehicle would approach that of a wheelbarrow without specially-shaped cushioning pieces fitted at every control arm mounting point.

Most commonly made of rubber, these cushioning pieces are formally known as control arm "bushings". While these bushings serve as flexible mounting points, they have two main functions. First, they absorb and isolate the car's body and occupants from road shocks and vibrations. Secondly, they also serve to eliminate any loose play in the control arms - keeping them aligned snugly and firmly in proper position. This helps ensure all four tires stay firmly planted on the ground they way they were meant to.

Since bushings in your suspension take a pounding any time your vehicle is in motion, any rubber or other compounds used to make them must be extremely robust and durable. And, generally, they do last for quite a while under most normal driving conditions - so much so that automakers don't specify any kind of replacement interval. However, these rubber bushings will eventually succumb to wear, tear, and dry-rot over time. When one or more suspension bushings give up the ghost, you've got metal-on-metal contact creating noise, vibration, and harshness.

Signs of Worn Control Arm Bushings

Wheels and tires on the vehicle can play a big role in how long control arm bushings last. "Plus-sized" rim upgrades with larger wheel diameters and shorter tire sidewall heights transfer more shocks and vibrations through the vehicle's control arms. Because such rubber tires are less capable of absorbing bumps in the road, the rubber control arm bushings ending up taking the pounding instead. This shortens their lifespan considerably.

When rubber bushings wear, the effects are similar to bone cartilage that has deteriorated. Stress on joints and related parts increases, and painful groaning noises may result. Components can shift out of their firmly-mounted, proper positioning as wear increases - allowing play and slop that causes a vehicle to wander and behave erratically at speed.

If you're experiencing banging noises, creaks, or frame-rattling vibration from the front or rear suspension, a good road test with a range of twists and turns at various speeds may help you isolate where the noise is coming from.

Worn control arm bushings will also have an influence on incorrect wheel alignment. On the highway, this will show up as wandering or failure to maintain a direction, more than an off-center steering wheel. It may be difficult to successfully perform an alignment because parts won't hold the position to which they've been adjusted.

Small bumps may seem extremely harsh if there isn't enough rubber to keep metal from hitting metal. Driving off a shallow driveway curb or making sudden braking maneuvers while steering (both at low speeds) will bring out a worn control arm bushing with a metal clunking noise. You may also experience steering wheel shimmy above certain speeds because worn bushings allow enough play for a control arm to wiggle and squirm around instead of staying properly fixed in position.

A key point we cannot emphasize enough is that replacing old rubber bushings with new ones goes a long way toward improving the ride quality of your vehicle - restoring the supple cushioning it had when driven out of the showroom.

If you see tire wear along one side that would normally indicate an improper wheel alignment setting, but the vehicle shows alignment specifications "within range" on a professional alignment rack, the issue can very well be caused by compromised control arm bushings. If this is the case, alignment settings can temporarily shift out of specification when the vehicle is moving.

If you have access to a lift, or you've got two jack stands to get both front wheels in the air, have a second person turn the steering wheel back and forth while you get underneath and listen for noises. It's worth a try, because you may be able to hear where the issue is.

While you're underneath, use a pry bar to see how much play there is at the connecting points of the control arms. Generally, you shouldn't see more than 1/8th of an inch of free play from the bushing. If you do, it's time to replace.

Control Arm Bushings - Replacement (Normal Street Driving)

If you've come to our website looking for new control arm bushings to restore your factory ride quality and suppleness, we've got well-made replacement control arm bushings that will deliver value today as well as long-lasting comfort and durability tomorrow. Replacement style bushings all feature an inner rubber core that's chemically bonded to both an outer metal shell and an inner metal tube that surrounds and makes contact with the control arm. The ones we offer are high-quality matches for factory thickness, dimensions, strength, and flexibility.

For a wide range of vehicles from the 1950s through today, check out OE-level replacements such as the Moog Control Arm Bushing Kit, Dorman Control Arm Bushings, Mevotech Control Arm Bushings, and AC Delco Professional Control Arm Bushings - just to name a few.

When it comes to more specialized vehicle applications, we've also got OE-level replacements such as the Monroe Strut-Mate Control Arm Bushing Kit (late model Dodge pickups with struts), KYB Control Arm Bushings (Honda & Acura models from 1986-2014), URO Parts Control Arm Bushing Kit (Mercedes/Volvo/other Euro makes 1950s-today), Mopar Control Arm Bushings (various Chrysler brands 1997-today), Omix-Ada Control Arm Bushings (various Jeep models 1984-today), and many more.

Entering your year, make, and model in the boxes along the top of the screen will allow our system to show you only products for your specific car or truck.

Control Arm Bushings - Performance (Mixed Street and Track Use)

In our Performance control arm bushings section, you'll find control arm bushings made of rugged polyurethane (polymer-based plastic) instead of rubber. When we say polymer-based plastic, you may picture a bushing that's completely rigid, hard, and unyielding. But that's not the case.

Polyurethane control arm bushings do provide squish to absorb bumps - so they work effectively in their role. However, because they have less squish than rubber, they will produce a ride that's noticeably firmer. This is great during aggressive driving and off-roading because your suspension will stay tighter and more buttoned-down under high-pressure conditions. Many customers who have made the switch for performance gains tell us they're very satisfied with the more direct steering and suspension feel of polyurethane bushings. Drawbacks are more road noise, vibration, and harshness at all times over all roads.

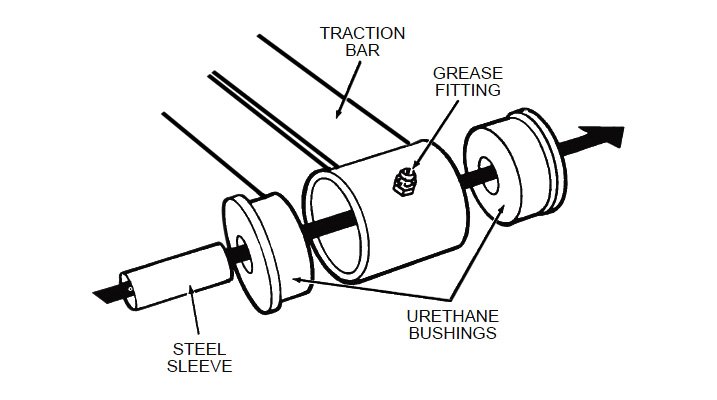

Like OE rubber bushings, polyurethane bushings also feature a metal outer shell and an inner metal tube which fits around the control arm. But because the polyurethane bushing piece itself is not chemically bonded to the metal pieces, it can literally rotate inside the metal shell as the control arms travel up and down. This causes a squeaking noise if the bushings are not kept properly lubricated.

While bushing engineers have created designs with internal grooves and edges that retain lubricating grease, some grease will still squeeze out over time. When it does, re-lubrication of the bushings is required - usually every few years. The process is relatively easy, as grease can effectively be squirted in between small gaps without having to take everything apart. Note that many performance control arms discussed earlier come with special grease fittings (also described as "zerk fittings") so that a grease gun can be used to inject some grease.

Generally, you'll want to follow the lubrication guidelines of specific bushing manufacturers - but if you drive over unpaved trails or roads with a lot of grit, the tell-tale squeaking noises may occur sooner.

Properly maintained, polyurethane bushings will typically last the life of your vehicle because they won't deteriorate, crack, and sag like OE rubber.

When it comes to performance control arm bushings, we've got a great selection. To name a few examples, there's the Energy Suspension Control Arm Bushing Set (wide range of American and import classics back to 1960), Prothane Control Arm Kit(1971-85 Toyota Celicas), Daystar Control Arm Bushings (older Jeep, Ford, and Toyota 4x4s), Rugged Ridge Suspension Control Arm Bushing Kit (Jeeps back to 1984), and the Fabtech Control Arm Bushing Kit (mix of American & import 4x4s).

As always, entering your year, make, and model in the boxes along the top of the screen will allow our system to focus on products specifically made for your car or truck.

Control Arm Bushings - Performance (Racing Only)

Competing on a racetrack where high g-force levels are present around every turn? We've got control arm bushings for select vehicles that will help you corner like you're on rails. Often described as the ultimate in stiff bushings, these eliminate all, or most of, the squish and play found in polyurethane bushings.

If you prefer no squish at all, we have the AFCO Steel Control Arm Bushings. Intended for perfectly smooth racetracks only, steel control arm bushings delete any and all deflection provided by rubber and even polyurethane bushings. Naturally, the use of metal bushings anywhere other than serious competition on a track is not possible because road impacts would be so hard and unforgiving that damage to various suspension components would quickly occur.

Because maintaining proper lubrication makes the difference between life and death with metal control arm bushings, they are equipped with grease fittings for frequent servicing.

For classic 1960s-70s GM performance cars, the Global West Del-A-Lum Control Arm Bushing Kits are available for upper and/or lower control arms depending on vehicle application. "Del-A-Lum" refers to the type of bushing setup, which is basically a metal inner bushing surrounded by a durable, rigid plastic liner tube that's encased in an outer metal shell. The plastic tube allows bushings to pivot without metal-to-metal contact. And while those plastic liners provide a tiny amount of squish, the ride produced is still extremely stiff. Opinions vary as to whether these should be driven over potholed roads, but we recommend using them on racetracks only.

Sample Customer

Chet had wanted a classic car for eons, but all he could afford was a project car. No matter: he found his dream car, a 1967 Ford Mustang, with a solid body but needing everything mechanically. He and his brother Lenny, who was a professional tech, tackled the job together.

When they got to the front suspension, they looked at both "repair" and "performance" parts on CARiD. There was plenty to choose from on the repair side. Dorman manufactured both upper and lower control arms for this vehicle, which included the ball joints. However, the brothers were planning a bit of a resto-mod for the 'stang, and wanted to have greater flexibility for suspension settings, especially as they had yet to decide on a wheel and tire package.

On the performance side of the page, they found the Specialty Products adjustable upper control arms. Although there were no performance lower arms, they added Prothane polyurethane bushings to their shopping cart. As far as they were concerned, this combination gave them the best of all worlds for their super Mustang.

To sum things up, if you're happy with the ride comfort, overall stability, and lifespan of your original equipment control arms and bushings, you'll be pleased with the value and performance of our "repair" components - many of which provide an improvement over factory grade parts.

If you prefer to customize and spice things up a little with firmer handling, ride height changes, or trail readiness, you'll be satisfied with how a new set of performance components will get you where you want to be. Don't forget that if you've also boosted horsepower, overall handling may just be a bit more unstable without some of these suspension modifications.

To help make your shopping experience easier, we're glad to answer any questions you may have about control arms, bushings, and hardware pieces. We've got knowledgeable product reps on call seven days a week that will be glad to listen and share any expert advice possible - without high-pressure sales tactics. We look forward to hearing from you!