Seasoned professional automotive technicians often say if you're using too much physical effort during a repair, you're simply not using the right tool. This is true, and a perfect example is repairing and replacing suspension components. If you've ever done this type of work or attempted to do it, you know it can be trickier than merely loosening and tightening bolts.

For example, rubber bushings may need to be pressed out, ball joints may need to be pried out of spindles, and coil springs often need to be compressed for removal and installation. Without the right tools, these jobs would require superhuman strength. More to the point, attempting repairs without the correct tools can be injurious to your health. But with the right tools, these jobs can be done quickly and easily - with satisfactory results and without inadvertently bringing harm to yourself or your ride.

In this article, we'll look at some of the special tools that will prove extremely helpful during suspension work.

Ball Joint Tools

In suspension repair, odds are good you'll need remove and reinstall control arms, steering links, and various other components that use ball joints as their point of attachment. As their name indicates, ball joints consist of a round ball that nests snugly inside a curved socket. A good deal of force is required to remove most ball joints. For these jobs, we've got ball joint tools such as separator forks and kits with a variety of adapters and hardware you'll need to make this task easier. Kits such as the OTC Master Ball Joint Set feature over 50 pieces designed for universal use on domestic and imported cars, and OTC's Truck/Van/SUV Ball Joint Master Service Kit is designed for most American 4x4s and vans.

You'll read further on below about the specialized products we have for different functions as well as tools unique to certain popular vehicles. We've also got a wide range of low-vibration and high-vibration air hammer tools (some come as complete kits with chisels) - a tool we highly recommend for providing the extra driving force needed to loosen the most stubborn of ball joints. We've also got a wide selection of air compressors to power any air tools you may be interested in.

Fork Separators

Fork separators (also known as "pickle forks") are designed to wedge in between the narrow space found between a ball joint and a spindle. If necessary, use a hammer to drive the fork into that gap further until sufficient leverage exists to break any mechanical welds between the ball joint and the spindle. For tight space applications, we've got the Gear Wrench Ball Joint Separator that's only 12 inches in length, and we've got the larger Lisle Stepped Ball Joint Separator with graduated "stairs" built in to the fork tongs which prevent the fork from bouncing back during use.

Ball Joint Removal Kits

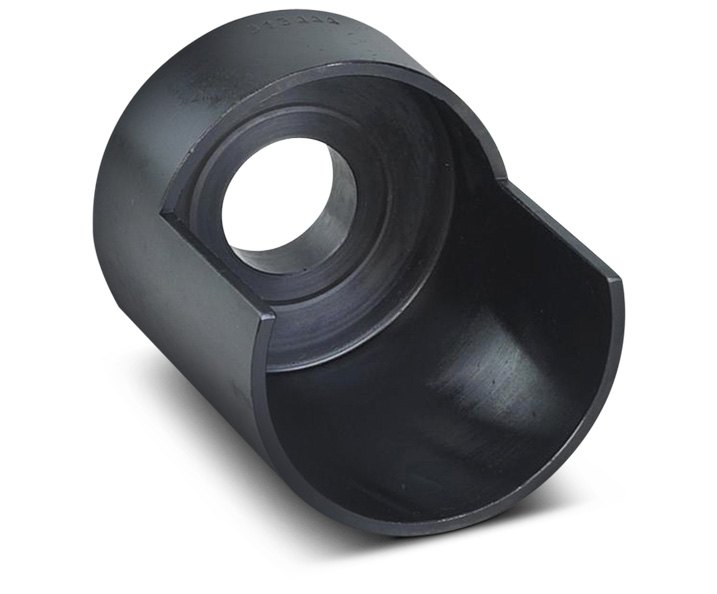

When it comes to removal and installation of parts such as ball joints, universal joints, and truck brake anchor pins, Astro Pneumatic Tool's Ball Joint Service Kit contains a "C" frame press, 3 receiver tubes, and a variety of adapters that are useful for removing rusted and corroded bits. Also included in the carrying case are a 4-wheel drive ball joint service kit for 1967-on Ford, GM, Dodge, International, and Jeep 4x4s with Dana 44 front axles.

For Hondas and Acuras (and other makes) built from the late 1980s through more recent years, we've got the Schley Products Honda/Acura Ball Joint R&R Tool that's purpose-built to service lower ball joints without the need to remove the steering knuckle or use a press. The kit includes three sizes of installer heads. (We've also got a specialized socket piece for Honda and Acura rear trailing arms as well.) If you've got a more recent Dodge 4x4 or Jeep model, OTC's Jeep/Truck Ball Joint Set comes with a complete set of adapters as well as a specially-designed C-frame tool that provides the clearance needed to separate ball joints on these vehicles. OTC also notes that this larger C-frame and replaceable screw tip allow these adapters to be used for other applications.

OTC's Ford Ball Joint Remover tool enables you to quickly remove the lower ball joint on 1992 to current 3/4- and 1-ton vans (E-250 and E-350) when used with ball joint service set No. 7249. For Ford trucks and SUVs from the late 1990s through the early 2000s, there's the Ford Ball Joint Update Adapter Kit.

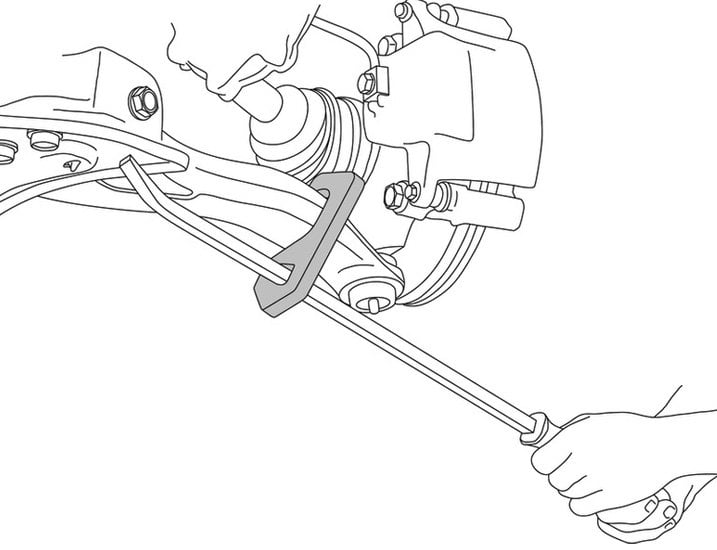

When you're dealing with lower control arms, it sometimes takes a lot of downward force on the control arm before things finally pop loose from the ball joint stud. A pry bar alone helps, but in order to exert maximum force with it, you'll need a specialized piece that gives you a different angle of leverage on the pry bar which isn't normally attainable. Lisle's Lower Control Arm Tool Chassis Ball Joint Tool fits around your vehicle's lower control arm, and a rectangular hole allows pry bars up to 3/4 inches to be inserted where they can exert maximum force without any danger of slipping out of place.

Spring Compressors

Coil springs are very common suspension component found on all kinds of cars, trucks, and SUVs. Because they support the vehicle's weight, they are made of strong steel, and in their installed location, are under a huge amount of compressed tension.

We cannot stress enough that coil spring service work requires the utmost in care, along with the use of appropriate tools. A coil spring under tension which is improperly released can seriously injure or kill you. Always work safely!

Before you can remove any coil spring from its mounting point on a vehicle or on a strut, it must be clamped down to a shorter height. Because tension created during the compression of a spring must be carefully managed in order to ensure safety and prevention of injury, we've got a selection of spring compressors designed for every type of spring and every budget - making easy and safe work of this tricky task.

Wall-Mount And Stand-Mount Spring Compressors

MacPherson strut assemblies have the advantage, at least for most vehicles, of being removable as an assembly without compressing the spring. Once the assembly is off the car, it can be brought to a work area where the spring can be compressed, allowing further disassembly.

Stand-alone units are great if you are doing a lot of strut work. If you've got the wall space, we've got the Branick Wall Mount Strut Spring Compressor which bolts to a fixed vertical surface of your choice. It's rated to handle heavy-duty, extra-length, narrow, and angled coil springs without the need for extra adaptor pieces. Or if you prefer, we've got OTC's "Struttamer" Spring Compressor that's available by itself or with its own portable stand. Both versions include an extra "bridge" bracket piece that allows further compression of springs that normally can't be compressed enough to loosen the top retaining nut. It's designed to handle heavy-duty straight, offset, or conical coil springs typically fitted to full-size truck struts, with long handle arms that boost leverage when you're tightening the screws.

Both of these coil spring compressors feature cross-bracing to ensure the frame of the tool doesn't flex under heavier loads, and both of them come with adjustable arms which can be positioned higher or lower (or further inward) as needed to handle a wide variety of coil spring diameters.

Portable Spring Compressors

If you don't want to spend the money (or don't have the room) for one of the large units above, you may benefit from the portability and value of the compact spring compressors we offer. Unlike the larger spring compressors in which the entire strut assembly is inserted inside, portable spring compressors are smaller in size and can easily be carried to wherever they're needed. Depending on your vehicle, these can be used with the strut still mounted to the car OR can be used at a work bench with the strut assembly mounted in a vise. With the two compressor arms mounted on opposite sides of a spring, compression is achieved by turning the main bolt with hand tools - increasing the tension on one side and then the other in even increments.

For starters, there are the budget-priced Sunex 2 Piece Coil Spring Compressor and the GearWrench MacPherson Spring Compressor, both featuring smaller one-sided hooks. Moving up, OTC's Strut Spring Compressor Kit With Safety Lock features quick-release pins that lock each clamp in place around the spring coil. And if you need a portable spring compressor designed for slightly heavier-duty springs that are straight or curved, GearWrench's Coil Spring Compressor features larger clamp hooks.

Shock Absorber Removal Tools

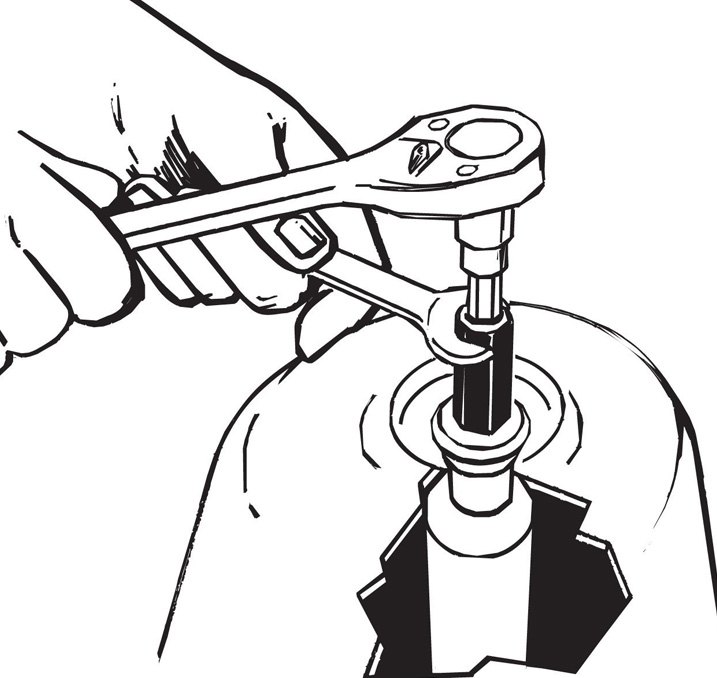

Loosening the top of a shock absorber on a MacPherson strut vehicle means breaking it free from the top of the strut tower. This requires a special socket piece that's essentially two sockets in one. A small, narrow "stem socket" sits in the center of a larger socket piece, and both of them can rotate independently of one another. This allows the stem socket to fit over the top of the shock stem while the larger socket fits over the surrounding nut. As one is held in place, the other is turned.

For this task, we offer one specialized socket by itself with Lisle's Shock Absorber Tool, and we offer an entire kit with multiple sizes of socket pieces in the Steelman Strut and Shock Instalation/ Removal Kit. Note! NEVER remove the top center nut on a MacPherson strut (whether mounted to the car or not) without first compressing the coil spring.

Bushing Removal Tools

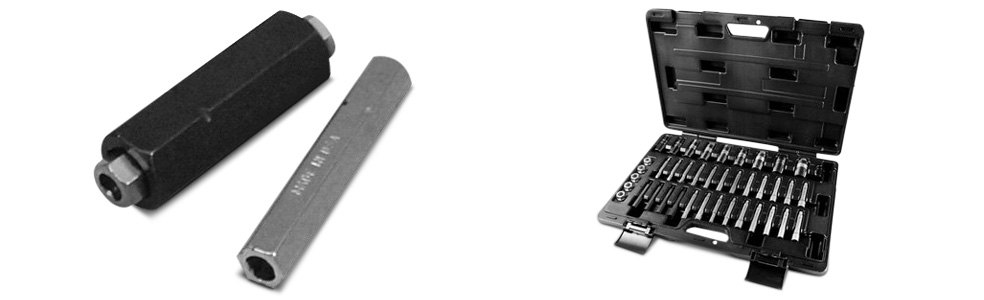

You'll find any number of rubber bushings throughout your vehicle's suspension, mounted in the eyeholes of control arms, leaf springs, shock absorbers, suspension/structural support braces, steering components, and much more. Without them, the ride of your vehicle would be harsh, noisy, and full of vibration. Professional technicians say you're not really ready to perform suspension repairs unless you're prepared to remove (or "press out") the myriad of bushings you'll come across - many of which won't show their deteriorated condition until things are taken apart. Because special tools and specially applied pressure are required to successfully press out bushings, we've got kits with small, medium, and large tools (known as "drivers") that will allow you to easily remove and install bushings.

For value, we've got the GearWrench General Purpose Bushing Driver Kit with multiple drivers and adaptor pieces from 3/8" to 1-3/8" that will be useful on bushings found in most cars and trucks as well as buses, tractors, off-road equipment, and even construction vehicles. We also offer the more comprehensive Schley Products Manual Bushing Kit with 22 cups and receiver bits that can be combined to create hundreds of size combinations. Engineers who created this kit envisioned and created bits that are shaped to allow replacement of numerous suspension bushings without having to remove parts from the vehicle in many cases.

Owners of Hondas and Acuras may want to invest in the Schley Products Honda/Acura Bushing X-Tractor clamp that's specially designed for easy removal and installation of trailing arm bushings without disconnecting brake shoes, brake lines, rotors, calipers, and e-brake cables. Included with the clamp is an adapter ring necessary on 1990-93 Acura Integras. While results will vary depending on your own experience and skill, Schley Products claims total replacement time for trailing arm bushings will be a quick 15 minutes per side rather than Honda's quoted book time of almost 2 hours per side.

Anchor Pin Bushings and Leaf Spring Eye Bushings

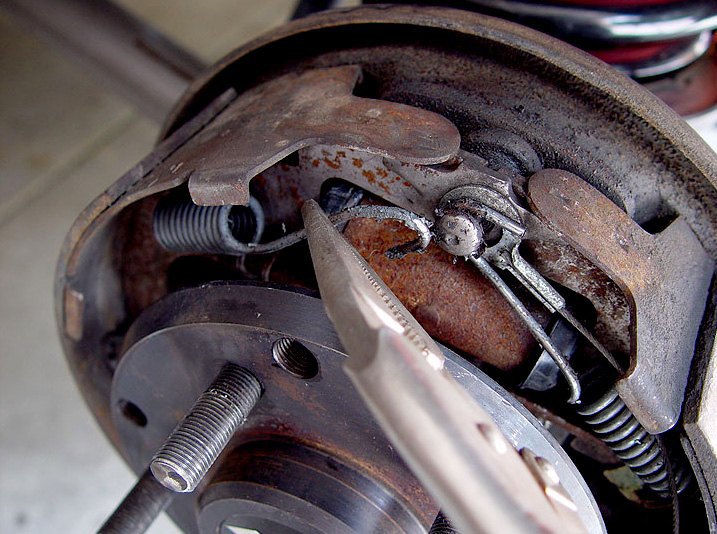

An anchor pin is a fixed component on a drum brake assembly which stops the brake shoes from moving at a certain point so that they don't continue to rotate with the brake drum. In order to avoid harsh clunks when these components come in contact, a rubber bushing exists for the anchor pin. When it's time to replace this bushing, Lisle's Anchor Pin Bushing Remover is a pneumatic driver set that presses this bushing out of its nest. It's also useful for removing similarly-sized bushings on the eyeholes of leaf springs.

Hydraulic Shop Presses

If you need a significant amount of force to press certain suspension parts in or out, a hammer or a hefty C-clamp isn't always going to cut it. A hydraulic shop press can provide anywhere from 12 tons to 55 tons of force. Presses are available in both bench-top models and floor models, giving you lots of options depending on your available space and funds.

For best value, consider the AFF 812 shop press or ATD 7453 shop press, both rated at 12 tons, and both floor mounted, which gives you room for larger objects on the press bed. Among 20-ton units, you have a choice of the AFF 820, the ATD 7454, or the Sunex 5220, again all floor-mounted presses. For the biggest of jobs, you can choose between the AFF 837 or the OTC 1850; the AFF is rated at 50 tons while the OTC is the champ at 55 tons. Tight on space, and don't need 50+ tons of pressure? We have the answer in the ATD 7452 12-ton bench press.

In this article, we have highlighted just some of the many tools available in the Suspension Service Tools section of our website. Be sure to scan through here, as you may find tools designed to work with your particular vehicle year, make, and model that we have not featured. Suspension repair may seem daunting, especially if you haven't tried it before. But it's our feeling that since no one is born knowing how to do any type of automotive fixes, popping out ball joints and pressing in bushings is something anyone can learn. We do recommend you take a minute or two to browse through sections of our website devoted to hand tools such as wrenches, sockets, and pry bars as well as air tools (designed for use with air compressors) such as air hammers, cutting tools, grinders, impact wrenches, impact sockets, and more.

Ask any expert: there is no replacement for a good quality tool to get the job done quickly, correctly, and safely. We promise, having some or all of these tools will save you time, effort, and the expense of replacing additional parts that can become damaged through the makeshift use of improper tools. We invite you to contact us 7 days a week with any inquiries you may have.