If you've decided it's time to replace the clutch on your manual-transmission car, you've reached the point where advantages (crisp, new-feeling response) have come to outweigh disadvantages (significant labor costs or time spent doing it yourself). Whether you don't have a choice because your old clutch slips badly, or you want to take initiative and upgrade your vehicle by sharpening performance off the line, you have high expectations about the finished result once high labor costs are paid or you've spent a lot of time and effort doing it yourself.

You're anticipating silky release and take-in of the clutch pedal, smooth running without harshness or vibrations, crisp shifts that chirp tires on pavement, and the fact that your vehicle feels brand new again. Knowing what's important when a clutch job is being done can get you those results and save you money, because taking shortcuts usually yields disappointment.

This article focuses on the three integral components that are part of a manual transmission clutch, what each one does, how the parts relate to one another, and why it's usually a best practice to replace all of them together. Most front-wheel-drive vehicles require 8-11 hours of labor to remove a brake assembly, wheel hub, and entire axle on one side in order to separate transmission and engine for clutch access. Many rear-wheel-drive cars require only 4-5 hours of labor because all that's needed to slide the transmission out of the way is to drop the driveshaft. Whatever the installation process is for your vehicle, you'll find that the labor cost still typically outweighs the material cost.

It's also important to remember that a clutch is an integrated system where all the related parts depend on each other. Replacing the clutch components as a set is usually the smartest thing to do. If the vehicle has a pilot bearing which supports the end of the transmission/transaxle input shaft, replace that as well. Worn pilot bearings will cause misalignment of the shafts, leading to fast wear of clutch and throwout bearings as well as problems during engagement and disengagement.

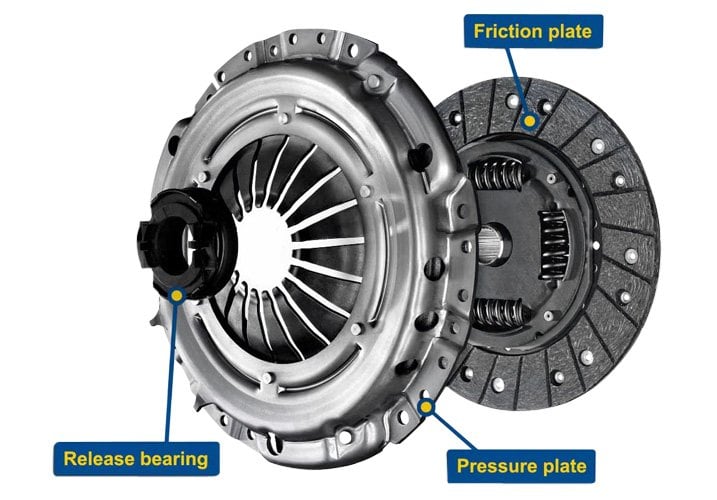

What A "Clutch" Actually Consists Of

A manual transmission "clutch" is actually made up of three main parts positioned between the engine's flywheel and the transmission input shaft. As clutch parts engage, they allow smooth coupling of the drivetrain as the clutch disc and flywheel come together to transfer driving force to the wheels. They can be clamped firmly together, disconnected entirely, or allow for an infinite amount of "slip" so that a vehicle can begin moving forward or backward progressively.

A clutch disc is a rotating circular metal plate splined to the transmission input shaft that's covered with friction material on both sides. The disc is located between the engine flywheel and the clutch pressure plate, and is clamped tightly between these two members when the clutch is engaged. Clutch discs may also be described as friction discs.

The clutch pressure plate is a spring-loaded metal plate that spins with the flywheel and applies pressure to clamp the clutch disc firmly between itself and the flywheel. When the clutch is engaged, springs in the pressure plate force the clutch disc against the flywheel.

A throwout bearing (or "clutch release bearing") is the component that is the connection between the clutch linkage and the pressure plate. When the driver depresses the clutch, this bearing pulls the pressure plate and clutch disc away from the flywheel to disconnect the engine from the drivetrain; when the driver releases the clutch pedal, it allows the springs to push everything back together and the clutch is engaged. The throwout bearing does wear and, in extreme cases, will squeal when the clutch pedal is depressed.

What It Means When Clutch Components Wear

By nature of what clutch discs are designed to do, their friction material is under a constant state of wear during the normal process of depressing and releasing the clutch. Naturally, a clutch disc needs to be replaced as a wear item. However, it's also important to note that problems with other clutch components can lead to uneven wear on the clutch disc, which in turn causes wear on these other components.

The flywheel, normally not considered part of the clutch assembly, can be subject to wear or overheating. So even if another clutch component is found to be the source of a problem, replacing the friction disc at the same time will help keep you out of trouble.

Like any spring-loaded device, a pressure plate's springs (or "fingers") tend to weaken over time, which can cause clutch slippage from lack of pressure. This problem is almost impossible to tell by looking at a pressure plate that been subject to normal wear, but one that is severely worn will usually make a rumbling or growling sound when the clutch is engaged. As throwout bearings wear, they can cause misalignment issues that cause damage to other components.

Clutch Kit Packages

Clutch discs, pressure plates, and throwout bearings are often sold in sets together and are priced favorably compared to the cost of buying replacement components separately. Depending on vehicle design and manufacturer recommendations, some kits may also include pilot bearings for the input shaft.

In many cases, manufacturers will only offer these items together as a complete kit because they feel if a clutch disc has reached the point of wearing out, other parts have reached that point as well. If the engineers that designed, built, and tested your vehicle observed these conditions in order to reach that conclusion, their advice is well worth heeding.

Again, given the amount of labor which is involved in accessing the clutch components, it may be "penny wise and dollar foolish" to replace only the worn component, when you now know how these components function in relation to each other.

In the Clutch Kits & Components section of our website, you’ll see checkboxes for both OEM style Replacement Clutches as well as Performance Clutch Kits. Once you select your preference, you’ll be able to further narrow your search via check boxes that display kits with or without flywheels.

OEM Style Replacement Clutch Kits

When it comes to factory style replacement clutch kits, we’ve got the LUK RepSet Clutch Kit, RhinoPac Premium Clutch Kit, Exedy OE Replacement Clutch Kit, and the Valeo Clutch Kit – all of which are offered for a wide range of makes and models. The Genuine Clutch Kit includes components for newer Nissan/Infinitis as well as older Honda/Acura and Porsche models. For Jeeps back to 1946, we’ve got clutch kits from Omix-Ada and Crown.

If you’ve got a vehicle originally equipped with a complex dual-mass flywheel design, the Valeo Clutch Flywheel Conversion Kit and the Beck Arnley Clutch Flywheel Conversion Kit are designed to convert your vehicle to a more traditional single solid flywheel replacement setup. Even though they’re not a match for factory equipment, the new flywheel you’ll receive has been engineered to work extremely well with the vehicle the way any OEM equipment would.

Performance-Oriented Clutch Kits

If you’re interested in high-performance street driving, towing, or competitive track-only use, we’ve got performance-oriented clutch kits geared toward your individual needs.

These kits are ideal for cases where greater demand will be put on a clutch because of horsepower upgrades. Or, because you’ll be trailering a heavy load. Performance kits typically include pressure plates that can handle significantly more clamping force. Check boxes along the left of the screen allow you to narrow your search to kits that contain from 1 to 4 clutch discs. Plus, you can view kits that contain clutch discs made of organic compounds, ceramic compounds, Kevlar, carbon, or iron.

Alignment Tools

Clutch alignment tools can be a lifesaver when replacing any clutch components. Basically a fitted shaft, this tool is designed to be inserted into the center of the pilot bearing where it snugs in place temporarily. After the alignment tool is in place, clutch disc and pressure plate pieces can be slid directly over the alignment tool (a hole in the center of each makes this easy).

As you bolt the clutch disc and pressure plate in place, the alignment tool supports and keeps them aligned just where they need to be in order for things to line up properly. We’ve got vehicle-specific tools that are shaped and sized for the transmissions found on specific makes and models, and we’ve got universal-fit tools available in a variety of dimensions.

Flywheels - When They Should Be Changed

Since your old clutch disc has had a direct relationship with the engine's flywheel over many miles, inspecting the flywheel when things are apart is essential. The most important thing to check is the flatness of the flywheel because any small degree of warpage (or "runout") will cause problems. Using a dial indicator or a straight edge across the flywheel at different points will give an indication if there's any wobble.

Some manufacturers say runout up to .005 inch for every inch of flywheel diameter is acceptable, but many automotive engineers feel anything over .002 inches of runout per inch will create noticeable vibration, clutch chatter, and related issues. It's a safe bet that any runout over .005 inches creates the risk of clutch failure from extreme vibrations, uneven clamping, etc.

Inspect the flywheel for cracks – especially around holes for mounting bolts. If cracks are deeper than surface scratches, the flywheel should be replaced in order to avoid the likely possibility it will shatter at high rpms and damage the transmission itself. Check for obvious "hot spots", places where the flywheel may have overheated, or where clutch disc material was deposited on the flywheel surface. Check the starter motor teeth around the circumference of your old flywheel to make sure none have broken off. (These teeth are also known as the "ring gear". On some flywheels, this part is replaceable separately.)

Resurface Or Replace The Flywheel?

Reviews are mixed and opinions vary on the subject of resurfacing flywheels when doing a clutch job. (Resurfacing consists of cutting a new surface on the flywheel by removing a minimal amount of material, resulting in a smooth flat surface again.) Some vehicle manufacturers strongly advise against any resurfacing and recommend flywheel replacement if the old one looks questionable. Yet others claim it's a valid process, saying clutch discs grab better because of the fine, even ridges left after a lathe grinds surface metal flat again.

One vehicle owner who didn't resurface his flywheel when installing a competition-grade clutch claimed he did not see performance benefits until he took the transmission back out to do so. Dual-mass flywheels consisting of two sections bolted together should never be resurfaced because of balance issues likely to be created.

Because flywheels can become scored and hotspotted with hardened patches during thousands of miles of performance driving, leaving an old flywheel as is will definitely shorten the lifespan and function of any new clutch being installed. If your clutch disc became extremely worn and failed, odds are very high your flywheel is scored enough to require replacement.

Unless you enjoy dropping the transmission out of your car on a regular basis, we recommend replacing a flywheel that shows any signs of wear or damage when performing a clutch replacement. Simply put, a new flywheel will work properly every time, but resurfacing has the potential to allow some problems to linger.

Even New Cars Need Some Clutch Love

Just because your manual-transmission car has only 10 or 20 thousand miles on it doesn't mean that the clutch is still perfect. Driving style is the number one factor which determines clutch longevity (or lack of it!). And remember that almost all car manufacturers consider the clutch assembly a "wear" item, like tires and brakes. If you wear out your clutch and your vehicle is still within its New Car Warranty Period, it is very unlikely that the replacement would be considered a warranty job.

No matter if your ride has traveled 20,000 or 200,000 miles, clutch replacement is a big job. Whether it's the clutch disc that's shot, or some other related component, your wisest decision at the time of repair will be to replace all the clutch assembly components. You will save time, money, and aggravation in the long run.