Is it possible that you take your vehicle's tires for granted? Perhaps you think of them as nothing more than "donuts" which are carved from a single solid piece of rubber. When you purchase a set of tires, do you seek out the least expensive ones, presuming that all tires are the same? If we explore the manufacturing process of tires, we can better appreciate a tire's complexities, and can better understand why some tires cost more and perform better.

There can be quite a spread among new tire prices. You can spend as little as $60 for a tire for an old Volkswagen, and over $450 for a high-performance one for an Audi S6. Most new tires for modern cars and trucks fall in between these two extremes. Yet the way each tire is manufactured differs very little. Besides size (in general, the larger the wheel, the more expensive the tire), it's the differences in the inner construction and materials which contribute to the final cost. Tire makers take all these factors into consideration.

Basic Understanding Of Tire Manufacturing Techniques

Why should this matter to you, the tire customer? We firmly believe that an informed consumer is a more satisfied consumer. Having a basic understanding of tire manufacturing techniques can only help you at decision time. If tire "A" costs "X", and tire "B" costs 50% more, and you learn that tire "B" has stronger plies and a greater number of them, this can overcome concerns and questions about the price difference. Let's now try to understand the manufacturing process in more detail.

While the rubber exterior is what's visible to the eye, in fact, a tire consists of many different materials, including carbon black, oil, silica, steel, polyester, and other additives. The manufacture begins on a drum which is part of a tire-assembling machine. The drum can be made wider and narrower during the build-up. First, a layer of rubber that is air-tight is rolled onto the drum. This first layer takes the place of the inner tube, which is no longer needed. This layer helps keep the air inside the tire.

Next, a number of belts are placed on top of this initial rubber layer. The exact number and composition of belts varies greatly among tire manufacturers, and within each manufacturer's different tire models. The belts are made of woven steel and/or polyester, and give the tire tread much of its strength. These belts are considered the tire's plies. Depending on the tire, pieces of rubber along the outside may be placed down, to eventually become the sidewalls.

Two steel hoops are then placed on the outside edges of the drum. These form the bead, which is the part of the tire that seals against the lip of the wheel. The machine folds a layer of rubber over these steel beads so that they are encased, which prevents unwanted metal-to-metal contact between the beads and the wheels.

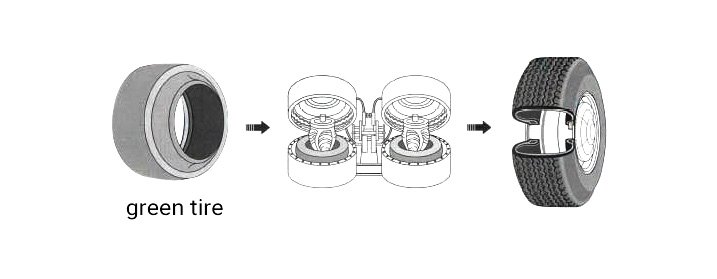

Once all the belts have been wound onto the drum, the rubber outer layer is wrapped on top of the belts. We said earlier that the drum holding all these layers can be made wider or narrower, and the next step is where that becomes necessary. The drum becomes narrower, pushing the outer edges on each side toward each other. The former "flat" shape of all these layers becomes closer to a tire's real shape, with a tread and sidewalls. At this stage, this is known as a "green tire".

Next, the tire is put inside a mold. Water or steam is pressurized inside the tire at a very high temperature. It's held there for a few minutes or a few hours, depending on the size of the tire. This step accomplishes several things. First, the heat (around 300 degrees F) melds all the layers together, in a process known as vulcanization. Also, the pressure pushes the tire against the walls of the mold. This forms the tread pattern, plus all the markings on the sidewall. After the tire comes out of the mold, it's ready to be mounted on a wheel and installed on a car or truck.

The manufacturing process greatly affects a tire's performance: how long it lasts, how quietly it rides, how well it tolerates potholes, and how quickly it sheds water. All of this depends on its design, which influences the details of its manufacturing. The tire's very safety and handling depend on its making. Keep this in mind as you shop for tires. Most tire makers indicate the material and number of plies as part of the tire's specs. We're not suggesting that you should always buy the most expensive tire, but weigh the cost, construction, and the materials against your needs, wants, and budget.