When you've taken a stock engine and built it up into a more powerful mill, upgrading the starter is a final step that's commonly overlooked. When a new or rebuilt engine is installed with the original (or OEM-spec) starter fitted, it may struggle to turn it over; getting those pistons to move up and down fast enough sometimes becomes a challenge.

This happens because a higher-compression engine is harder to spin. Tighter clearances and higher compression create additional pushback on a starter motor, so more torque and higher rpm's are required to fire up the engine smoothly and consistently.

Motors that have ignition timing with a high amount of initial spark advance (the number of degrees before top dead center when ignition occurs) require more muscle to get started. Some racing engines are even equipped with devices that retard spark timing during starts. Engines fitted with more aggressive camshafts usually feature very stiff valve springs also, adding to the starter's workload.

To solve cranking problems inherent with high-power engines, we offer a number of performance starters that provide extra power and rpm's needed for all types of upgrades - from minor modifications to alcohol racecar engine swaps. Starters we sell are vehicle-specific with mounting holes in the exact locations needed for installation on your year, make, and model.

Mounting brackets and other hardware necessary for installation will also be included. Many of the starters feature adjustable mounting positions, so they can be rotated out of the way to clear other mechanical items if necessary.

How Performance Starters Are Measured

On many of our product pages, you'll see starter motor output ratings as well as ratios. For comparison, the amount of power a starter motor produces will be stated in either Kilowatt or Horsepower form (1 kilowatt equals 1.34 horsepower).

It's important to note that these power ratings refer to the amount of twisting force produced by the electric motor within the starter assembly. They do not refer to the force found at the end of the actual output shaft that connects to the vehicle's flywheel.

This is because performance starters also feature a gear reduction ratio. This allows the electric motor to spin multiple times for every 1 revolution of the starter's final output shaft. Gear reduction ratios usually fall between 3.5:1 and 4.5:1 - and this ratio can boost the actual twisting force delivered to the engine.

Many OEM Starters Lose Cranking Power When Hot

Many original equipment starters suffer from "heat soak" problems. This means when they get hot, significant cranking power is lost. Direct-drive starters without gear reduction tend to heat up quicker during use because they draw more current, plus all components inside are spinning faster. Heat from nearby exhaust pipes (especially headers) can also affect a starter, contributing to sluggish performance when re-starting a hot engine which may already be suffering from temporary "vapor lock".

Conversely, performance starters with gear reduction are more resistant to heat buildup because they end up drawing less current, thanks to designs that are more efficient. If equipped, aluminum outer housings dissipate heat away more effectively - whether that heat is coming from armatures and solenoid contacts inside, or from exhaust heat outside.

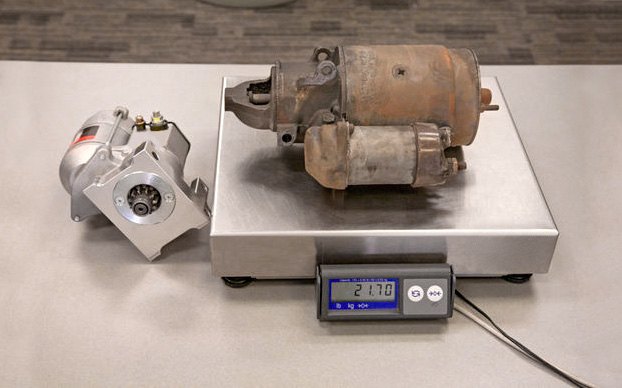

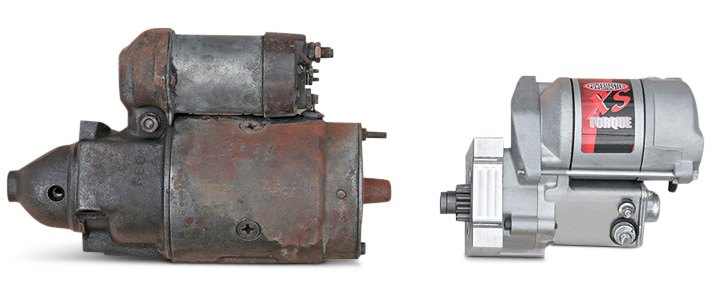

Naturally, those aluminum housings also reduce weight compared to steel ones. Combined with smaller overall size, it's not uncommon for performance starters to weigh between 10 and 12 pounds - almost 50% less than OEM equipment. Removing 10 or more pounds from your vehicle is worth doing, especially while achieving a worthwhile upgrade simultaneously.

Best values on performance starters typically feature steel housings, and we've got them from Proform, Chevrolet Performance, and MSD - just to name a few.

Moving up to lightweight aluminum housings, we've got the CVR Protorque Ultra, Extreme and Maximum, Tilton Severe Duty, and even the Powermaster Ultra Duty Diesel Starter for full-size American truck engines back to 1982.

Performance Starters Also Available In Smaller Sizes

Sometimes described as "mini" starters, performance starters of a smaller size can really save the day when clearance is reduced because of aftermarket exhaust headers or wider oil pans. And if you're swapping a bigger engine into a smaller vehicle, space-saving performance starters may be the only logical option.

Examples of compact performance starters are the Powermaster aluminum Ultra High Speed Torque Starter - designed for engines requiring higher than normal crank speed. When maximum muscle is needed, the XS Torque Starter is a great choice for owners of 1966-79 VW air-cooled models, 1967-87 AMC vehicles, and other American makes.

We've also got the Ford Performance aluminum Hi-Torque Mini Starter (1955-2001 Ford/Lincoln/Mercury vehicles), and the B&M aluminum Star Tek Starter.

Wiring Between Battery And Starter Plays An Important Role

If you've been having issues with your OEM starter, it's important to make sure weakened cranking power isn't being caused by compromised electrical wiring. Because starter motors have such a heavy draw, there's an individual designated cable running from battery to starter. While this cable is well insulated with thick rubber, copper wiring inside still develops corrosion and electrical resistance over time. This resistance prevents electricity from passing at a normal flow rate - a problem that will continue to plague any new starter installed. A common contributor to wiring corrosion is extra heat from aftermarket exhaust systems that are mounted in close proximity.

Even if OEM wiring is fine, it may be undersized for a performance starters at the high end. Undersized cables that can't deliver necessary current will cause a starter to underperform the same way corroded wiring does. Replace any underperforming positive cables along with negative ones for grounding. You can find a great select of these heavy-duty cables in our dedicated online store.

It would be a shame if you spent hundreds, perhaps thousands, of dollars on a high-end engine rebuild, only to have starting problems because you reused the starter motor. Don't take a chance with getting stuck! Get you lighter, more powerful starter motor today, and bolt it into place. You will be happy that you did.