Oil Pumps & Parts

Select Department

-

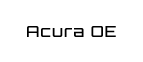

Save up to 29%Mopar® - Engine Oil Pump Gasket$15.43 - $47.07$21.01 - $65.99Save up to 29%

Save up to 29%Mopar® - Engine Oil Pump Gasket$15.43 - $47.07$21.01 - $65.99Save up to 29% -

Save up to 17%Mopar® - Engine Oil Pump Relief Valve$4.75 - $15.93$5.41 - $19.13Save up to 17%

Save up to 17%Mopar® - Engine Oil Pump Relief Valve$4.75 - $15.93$5.41 - $19.13Save up to 17% -

Mopar® - Oil Pickup Tube Seal$8.16 - $11.95

Mopar® - Oil Pickup Tube Seal$8.16 - $11.95 -

Save up to 22%Mopar® - Oil Pump Cover$4.38 - $35.22$5.00 - $42.43Save up to 22%

Save up to 22%Mopar® - Oil Pump Cover$4.38 - $35.22$5.00 - $42.43Save up to 22% -

Save up to 32%Mopar® - Oil Pump Drive Gear$31.24 - $192.71$37.74 - $282.54Save up to 32%

Save up to 32%Mopar® - Oil Pump Drive Gear$31.24 - $192.71$37.74 - $282.54Save up to 32% -

iD FastTrack Extra Save $4.00Mopar® - Oil Pump Rotor$83.59 - $831.93 + Save up to $4.00 with iD FastTrack

iD FastTrack Extra Save $4.00Mopar® - Oil Pump Rotor$83.59 - $831.93 + Save up to $4.00 with iD FastTrack -

Save up to 27%Mopar® - Oil Pump Seal$4.15 - $11.01$5.30 - $15.10Save up to 27%

Save up to 27%Mopar® - Oil Pump Seal$4.15 - $11.01$5.30 - $15.10Save up to 27% -

Genuine® - Diesel Oil Pump Fitting Update Kit$176.30 + Free Shipping with iD FastTrack

Genuine® - Diesel Oil Pump Fitting Update Kit$176.30 + Free Shipping with iD FastTrack -

Genuine® - Oil Pump Bolt$2.19 - $34.02

Genuine® - Oil Pump Bolt$2.19 - $34.02 -

iD FastTrack Extra Save $5.20Genuine® - Oil Pump Chain Guide$8.79 - $142.84 + Save up to $5.20 with iD FastTrack

iD FastTrack Extra Save $5.20Genuine® - Oil Pump Chain Guide$8.79 - $142.84 + Save up to $5.20 with iD FastTrack -

iD FastTrack Extra Save $6.40Genuine® - Oil Pump Chain Tensioner$13.33 - $238.31 + Save up to $6.40 with iD FastTrack

iD FastTrack Extra Save $6.40Genuine® - Oil Pump Chain Tensioner$13.33 - $238.31 + Save up to $6.40 with iD FastTrack -

-

iD FastTrack Extra Save $5.00Genuine® - Oil Pump Drive Gear$29.21 - $282.43 + Save up to $5.00 with iD FastTrack

iD FastTrack Extra Save $5.00Genuine® - Oil Pump Drive Gear$29.21 - $282.43 + Save up to $5.00 with iD FastTrack -

Genuine® - Oil Pump Flow Control Valve$257.36 + Free Shipping with iD FastTrack

Genuine® - Oil Pump Flow Control Valve$257.36 + Free Shipping with iD FastTrack -

iD FastTrack Extra Save $3.00Genuine® - Oil Pump Flow Control Valve Connector$48.56 - $51.43 + Save up to $3.00 with iD FastTrack

iD FastTrack Extra Save $3.00Genuine® - Oil Pump Flow Control Valve Connector$48.56 - $51.43 + Save up to $3.00 with iD FastTrack -

iD FastTrack Extra Save $4.00Genuine® - Oil Pump Flow Control Valve Seal$28.17 - $79.17 + Save up to $4.00 with iD FastTrack

iD FastTrack Extra Save $4.00Genuine® - Oil Pump Flow Control Valve Seal$28.17 - $79.17 + Save up to $4.00 with iD FastTrack -

Genuine® - Oil Pump Gasket$1.14 - $53.64

Genuine® - Oil Pump Gasket$1.14 - $53.64 -

Genuine® - Oil Pump Pickup Tube O-Ring$6.02 - $7.14

Genuine® - Oil Pump Pickup Tube O-Ring$6.02 - $7.14 -

iD FastTrack Extra Save $2.80Genuine® - Oil Pump Relief Valve$18.99 - $55.24 + Save up to $2.80 with iD FastTrack

iD FastTrack Extra Save $2.80Genuine® - Oil Pump Relief Valve$18.99 - $55.24 + Save up to $2.80 with iD FastTrack -

-

Genuine® - Oil Pump Return Tube Seal$2.59 - $23.38

Genuine® - Oil Pump Return Tube Seal$2.59 - $23.38 -

iD FastTrack Extra Save $5.10Genuine® - Oil Pump Rotor$30.96 - $237.25 + Save up to $5.10 with iD FastTrack

iD FastTrack Extra Save $5.10Genuine® - Oil Pump Rotor$30.96 - $237.25 + Save up to $5.10 with iD FastTrack -

Genuine® - Oil Pump Shim$3.12 - $15.92

Genuine® - Oil Pump Shim$3.12 - $15.92 -

Genuine® - Oil Pump Sleeve$149.59 + Free Shipping with iD FastTrack

Genuine® - Oil Pump Sleeve$149.59 + Free Shipping with iD FastTrack -

iD FastTrack Extra Save $1.40Genuine® - Oil Strainer$27.83 + Save up to $1.40 with iD FastTrack

iD FastTrack Extra Save $1.40Genuine® - Oil Strainer$27.83 + Save up to $1.40 with iD FastTrack -

iD FastTrack Extra Save $7.00Standard® - Diesel High Pressure Oil Pump Hose$138.24 - $413.18 + Save up to $7.00 with iD FastTrack

iD FastTrack Extra Save $7.00Standard® - Diesel High Pressure Oil Pump Hose$138.24 - $413.18 + Save up to $7.00 with iD FastTrack -

iD FastTrack Extra Save $5.00Standard® - Diesel Oil Pump Seals$20.24 - $95.13 + Save up to $5.00 with iD FastTrack

iD FastTrack Extra Save $5.00Standard® - Diesel Oil Pump Seals$20.24 - $95.13 + Save up to $5.00 with iD FastTrack -

iD FastTrack Extra Save $3.40Standard® - Engine Oil Pump Solenoid$23.35 - $67.05 + Save up to $3.40 with iD FastTrack

iD FastTrack Extra Save $3.40Standard® - Engine Oil Pump Solenoid$23.35 - $67.05 + Save up to $3.40 with iD FastTrack -

iD FastTrack Extra Save $5.00Standard® - Oil Pump Solenoid$26.11 - $97.97 + Save up to $5.00 with iD FastTrack

iD FastTrack Extra Save $5.00Standard® - Oil Pump Solenoid$26.11 - $97.97 + Save up to $5.00 with iD FastTrack -

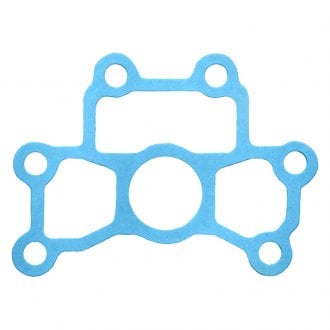

Fel-Pro® - Engine Oil Pump Gasket$1.60 - $22.80

Fel-Pro® - Engine Oil Pump Gasket$1.60 - $22.80

Oil pumps are generally very durable, but nevertheless the pump should be replaced or at least inspected when an engine is rebuilt. Once the pump is disassembled, inspect the housing and gears for scoring, nicks or other damage. The clearance between the gears and between the gears and housing should be checked against specification. Make sure the oil pressure relief valve moves freely. Rebuild kits are available for some pumps that include new gears, pressure relief valve springs, and the necessary seals and gaskets. The pickup tube and screen should be thoroughly cleaned to ensure unrestricted oil flow.

There are several variations of crank driven oil pumps. On a direct drive pump the pump surrounds the crankshaft and the drive gear is mounted to the end of the crank. On gear drive and chain drive pumps, the pump is mounted to the side of the crankshaft and driven by a set of gears or chain and sprockets. The gears or chain and sprockets should be inspected carefully and replaced if necessary. On crankcase mounted pumps, the oil pump driveshaft should be inspected for damage, especially for rounding of the hex at each end of the shaft where it contacts the distributor and pump.

Oil pressure switches and sending units are threaded into the engine oil galleries where they are directly exposed to engine oil pressure. A switch is used with a dash light. If oil pressure falls below a predetermined pressure, the switch will illuminate the light, alerting the driver that oil pressure is dangerously low. A sending unit is connected to a gauge that displays the amount of oil pressure. Oil pressure will be lowest at idle, but should rise as engine RPM increases. Oil pressure varies according to engine design; check the vehicle service manual specifications to see what is right for your engine.

Traditionally, racing engines have been built with looser bearing clearances to allow for the crankshaft flex that can occur when a high-powered engine is pushed to the limit. If clearances were tight, this flex could result in metal-to-metal contact and premature wear. However, to accommodate the greater bearing clearance a high volume oil pump is required. Regardless of your engine’s oil pressure demands, we have the pump to meet your needs.

We offer both cast iron and aluminum wet sump oil pumps with various volume and pressure ratings, so you can get the pump that’s right for your application. In addition to increased volume/pressure, many pumps feature strengthening in key areas to withstand the increased stress, and modifications to prevent pump cavitation. Many of our pumps come with the pickups pre-installed, but we also have a large selection of pickups for stock as well as performance oil pans. We also offer heavy-duty related components like stronger oil pump driveshafts with steel sleeves. In addition to a complete line of performance wet sump oil pumps, we also offer performance dry sump pumps.

Browse by Part Name

Featured Brands

Related Categories

Engine Assemblies

Engine Assemblies Motor Mounts

Motor Mounts Engine Blocks

Engine Blocks Valves & Valvetrain Parts

Valves & Valvetrain Parts Pistons, Rings & Connecting Rods

Pistons, Rings & Connecting Rods Oil Filters

Oil Filters Serpentine Belts & Auxiliary Drive Belts

Serpentine Belts & Auxiliary Drive Belts Valve Covers

Valve Covers Timing Gears, Chains & Covers

Timing Gears, Chains & Covers Engine Oil Pans, Drain Plugs & Dipsticks

Engine Oil Pans, Drain Plugs & Dipsticks Cylinder Heads

Cylinder Heads Timing Belts

Timing Belts Engine Pulleys

Engine Pulleys Engine Sensors, Relays, Switches & Connectors

Engine Sensors, Relays, Switches & Connectors Drive Belt Tensioners

Drive Belt Tensioners Oil Coolers

Oil Coolers Camshafts

Camshafts Crankshafts

Crankshafts Engine Management Systems

Engine Management Systems Engine Bearings

Engine Bearings Harmonic Balancers

Harmonic Balancers Engine Rebuild Kits

Engine Rebuild Kits Oil Catch Cans

Oil Catch Cans Balance Shafts

Balance Shafts Engine Swap Kits

Engine Swap Kits Engine Wiring Harnesses

Engine Wiring Harnesses Intercoolers

Intercoolers Throttle Bodies

Throttle Bodies Carburetors

Carburetors Motor Oils

Motor Oils

Browse by Vehicle

Oil Pumps Reviews