If you're considering upgrading your car or truck with larger custom wheels or OEM factory wheels, you've come to the right place. We’ve got lots of stylish wheels with a wide variety of finishes: chrome, black, matte, custom-painted colors, and much more. If you’ve seen a set of rims on a passing car or truck that you really like, we’re certain you’ll find them on our website.

In this article, we’ll cover some basic terms you’ll come across during the ordering process for any wheel. We will define terms you may not be familiar with – such as offset, centerbore, backspacing, bolt pattern, and more. These, and others below, are all measurements for different dimensions of the wheel, and each one affects whether a wheel is going to properly fit on your make and model. Just as the sleeve length on a shirt or the inseam on a pair of pants has to be right for them to fit your body, your wheels must have the right dimensions to fit properly on your car or truck.

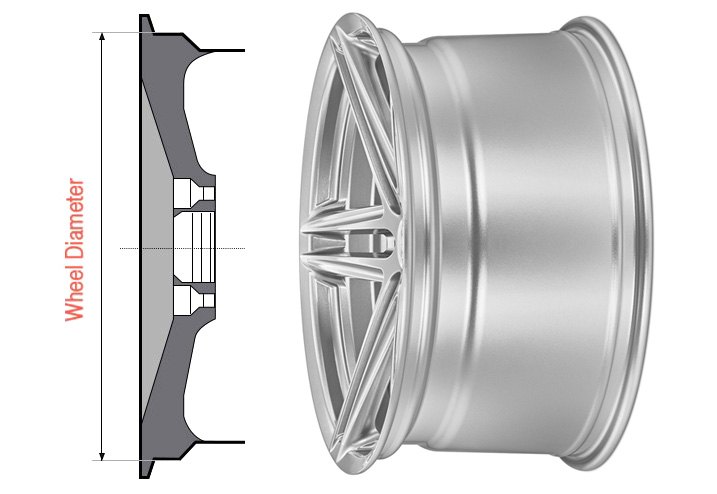

Wheel Diameter

What Is Wheel Diameter And How Is It Measured?

Diameter is the most familiar wheel dimension: When someone says they have 20" rims, they're referring to the wheel diameter. True diameter of a wheel is the distance between bead-seating areas (where the tire seals to the rim) as measured across the center of the rim, not including the wheel flanges. Wheel diameter determines how much of the wheel you see when looking at a car or truck. As diameter increases, more surface area of the wheel is visible.

It wasn't so long ago that 14" and 15" rims were standard wheel sizes for most cars, both as OEM equipment and as popular aftermarket designs. Today, 16" and 17" rims are standard on most lower-priced cars, with 19" and 20" factory option packages for performance models. And in the aftermarket, the sky's the limit with wheel sizes up to 30" and beyond. In fact, we’ve even got 34” wheels!

What Is Plus-Sizing?

When considering a larger diameter wheel, your goal is likely to maintain the same overall total diameter of your new wheel/tire package. This helps with speedometer accuracy, greatly maintains factory handling and braking, and negates the need for any other vehicle modifications.

This concept of increasing wheel diameter is called "Plus-Sizing". A plus one upgrade means the rim increases one inch in diameter, while a plus two reflects a rim diameter increase of two inches - and so on. But in order to maintain the same approximate tire diameter, the sidewall of the tire must become shorter as the wheel diameter is increased.

Our related article, Replacing Your Original Factory Tires 101, deciphers tire sizing in detail. If you’re not familiar with how to decode a tire size such as “195/65-16”, please take a look at this link.

Plus-Sizing works as follows: as the wheel diameter is increased, the aspect ratio (sidewall height defined as a percentage of width) is reduced so the overall tire diameter remains approximately the same. For example, a 205mm wide tire with a 55 aspect ratio on a 16" rim, expressed as 205/55R16, can be replaced with a 215/45R17 (plus one) or 225/40R18 tire (plus two) & rim combination and the overall tire diameter will stay within a few tenths of an inch. Note how the aspect ratio decreases in these examples, from 55 to 45 to 40.

What Are The Benefits of Plus-Sizing?

Besides seeing more beautiful rim and less boring black tire, another advantage of plus-sizing to larger diameter wheels is that your car will handle better and feel like it has sharper reflexes. This is because shorter sidewalls of low profile tires are stiffer and don’t flex as much – resulting in much less sway and wobbling of the sidewalls.

Lower-profile tires can be turned in a different direction with much less drag or effort. In short, this means tire responsiveness is quick and crisp when you turn the steering wheel, without mush and delay. Larger diameter wheels are usually wider as well, enabling wider tires to be mounted, so there’s more rubber on the road for increased traction.

What Are The Disadvantages of Plus-Sizing?

Lower-profile tires come with some disadvantages. Primarily, their shorter sidewalls provide less cushioning. This leads to a harsh and stiff ride over bad roads, and it puts tires more at risk to damage over potholes that otherwise wouldn’t be an issue. After a hard hit, a visible blister bubble may form in the sidewall if it becomes compromised internally - or the tire may blow out completely.

Reduced tire cushioning can also take its toll on alloy wheels, which are subject to becoming bent along their edges as they slam over deep potholes. This creates an out-of-round condition that must be repaired to avoid a shimmy. In worst-case scenarios, the wheel may even crack if the impact is severe enough.

Larger wheels tend to weigh more, which comes with a number of disadvantages. If you’re going up many wheel sizes, be prepared for the effects of increased rotational mass. For example, more horsepower is required to accelerate a heavier rotating mass than a lighter one. Fuel economy can suffer.

Likewise, more braking power is required for deceleration. Increased overall weight below the suspension level (unsprung weight) creates more inertia in the springs and shock absorbers and reduces their responsiveness. Heavy wheels and tires can also make the steering feel more sluggish.

Why Do Lifted Trucks Have Such Larger Diameter Tires?

Of course, we understand there are cases when you want bigger wheels and bigger tires for 4x4s with a lift kit installed. One of the many advantages of a lift kit, whether it’s 2 inches or 6 inches (or more), is the ability to fit humongous tires inside the wheel wells.

In this case, plus-sizing really doesn’t apply. Significantly larger off-road tires for trucks, Jeeps, and SUVs use a different tire measuring system than the one we referred to above. For an explanation, we invite you to read our related article Understanding Off-Road Tire Size Measurements for more details on the subject.

Can Incorrect Speedometer Readings Caused by Larger Tires Be Corrected?

Increasing the overall diameter of your tires can lead to inaccurate speedometer and odometer readings among other ills. To rectify this, we’ve got portable digital controllers that plug into any OBDII port and communicate with your vehicle’s onboard computer.

After punching in your original and replacement tire sizes, the digital controller tells the vehicle what your new correct calibrations should be. To see some specific controllers, check out our article Speedo Calibrators and Tranny Controllers Let You Re-Engineer Your Ride.

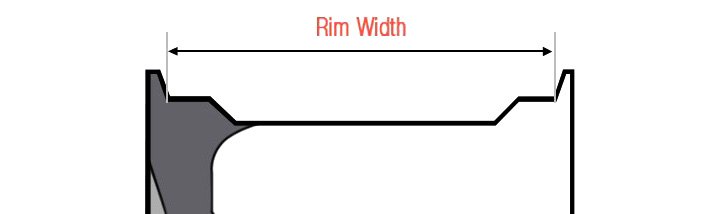

Wheel Width

What Is Wheel Width And How Is It Measured?

Wheel width is the distance between the bead seating areas across the wheel rim (it is NOT the distance from wheel outside edge to the opposite edge). Wheel width has increased partly in response increasing tire width. However, the most important consideration for wheel width is that it be the proper size for the tires that will be installed. Every tire manufacturer specifies a range of rim widths for each tire size; even within this range, the mounted width of the tire will change.

Once mounted, the tire’s actual width can increase by almost an inch in some cases when going from the narrowest to the widest rim allowed. This may not sound like much but it may be critical when selecting a tire and wheel package. A tire mounted on a narrower rim within the range may fit on the vehicle, but the same tire on a wider rim might not.

What Are The Pros and Cons of Running a Wider Wheel?

When properly matched, wider wheels with wider tires means there’s more rubber on the road for increased traction. Following this school of thought, there’s a reason that cars competing at the drag strips use super-wide racing slicks – they grip the road and get moving instead of spinning out. Wider tires perform better on skidpad tests – generating more cornering g-forces than skinny tires. And when it comes to stopping distances, wider tires can usually always scrub off speed faster without drama.

Wheels with larger width can weigh more, creating disadvantages discussed in Section 1 of this article. Wider tires fitted to such wheels are also more susceptible to following ruts in the road – pulling you from one side to another if you’re not paying attention. Wider tires do not cut a path in wet or snowy conditions as well as narrower tires, and are more likely to aquaplane and lose grip in heavy rain conditions. They have a higher rolling resistance, which means the engine must work harder to move more rubber over the road. When that happens, fuel economy suffers.

What Is Staggered Wheel Fitment?

Staggered wheel fitment means the rear wheels and tires on a vehicle are bigger and/or wider than the ones on the front. This has traditionally been used on rear-wheel-drive vehicles, because they need more grip at the back when it comes to putting power on the pavement. Some manufacturers of AWD vehicles have begun adapting staggered wheel and tire sizes.

That enhanced grip also enhances stability when powering out of a turn by preventing the rear end from breaking loose. For these reasons, many high-performance RWD and AWD vehicles come with staggered wheel fitment from the factory, and it’s why hot-rodders have supersized their rear tires since the dawn of the automobile.

If your vehicle is equipped with staggered wheels and tires from the factory, our website will guide you to recommended replacement sizes once you enter year, make, and model in drop down boxes. For more information, we also invite you to read our article on the subject What Is Staggered Wheel Fitment?

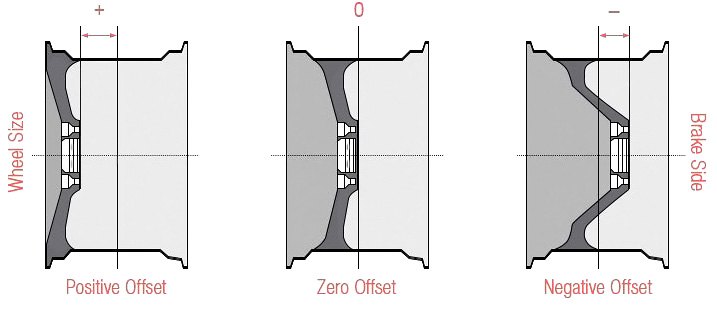

Wheel Offset

What Is Offset?

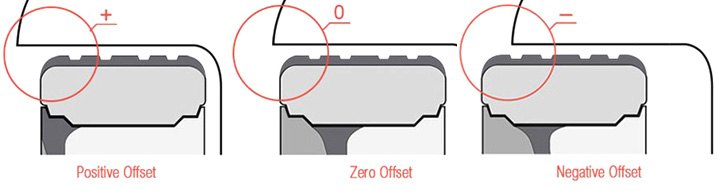

Offset is the distance between the wheel's hub mounting surface (where the wheel bolts to the vehicle) and the wheel's true centerline. On a wheel with zero offset, the hub mounting surface is at the wheel centerline.

If the hub mounting surface is toward the wheel face (the visible side of the wheel) side of the centerline, then the offset is said to be positive. This configuration places more of the wheel over the hub and brake components, and is common on front-wheel-drive cars.

Negative offset means the hub mounting surface is closer to the back side of the wheel, so more of the wheel extends outward from the hub. So called "deep dish" wheels tend to have a negative offset.

How Does Changing Wheel Offset Affect A Vehicle?

If you were to fit an aftermarket wheel with more negative offset than OE on your vehicle, the new rim and tire will stick out further to the outside. Potentially, you could have clearance issues between the tire and the fender.

Conversely, a new wheel with a more positive offset will sit in a more inboard position inside the wheel well. In that case, there is the potential for the wheel or tire to make contact with a brake or suspension component.

Visually, the difference will be noticeable. Wider custom wheels can easily increase the amount of negative offset, so it’s important to select those designed with an offset that’s the same or very close to your specific vehicle. If your owner’s manual doesn’t provide offset details under the specifications section, a call to your vehicle manufacturer should prove fruitful.

Our website is designed to guide you towards aftermarket wheels with offsets that maintain your factory handling without posing clearance issues. Once you’ve entered your year, make, model, and desired wheel size, a drop-down box in the Product Options field will present you with a choice of offsets that ensure a good fit.

Negative offset will literally widen your vehicle’s footprint, because the tire contact patches are further apart. While this reduces side-to-side load weight transfer and increases grip, it can make steering response sluggish in some makes and models.

When wider wheels create a more negative offset, you can easily run into fender clearance issues – especially when you consider that normal up-and-down wheel movement increases as you go further outward from the wheel hub.

In order to compensate for tires that fill the wheel well and rub the fender, you would need to modify the fenders. “Rolling” the fenders is one way, with a special tool that bolts to the wheel hub. As it’s moved back and forth, a roller wheel applies pressure along the fender lip to gradually push the sheet metal outward. If that doesn’t create enough clearance, cutting the metal and installing fender flares may be necessary. Both of these modifications are permanent, and may negatively affect the resale value of your vehicle.

Backspacing And Center Bore

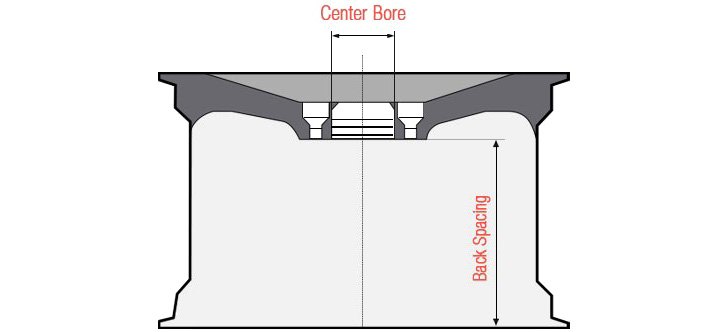

What Is Backspacing?

While offset measures the distance from the hub mounting surface and the wheel’s centerline, backspace is the distance between the hub mounting surface and the inner edge of the wheel rim. The offset and backspace must be correct on a replacement wheel to ensure the wheel and tire assembly fits properly inside the well without contacting the fender, frame or any other components throughout its range of motion.

What Is Center Bore?

The center bore is the machined hole in the center of the wheel designed to fit over the flange that extends from the wheel hub. This flange centers the wheel on the hub as the lugs are tightened to prevent wheel runout, which can cause vibration. However, the size of wheel hub flanges are not standard and vary according to vehicle manufacturer.

What Are Centering Rings And Why Might I Need Them?

In order to make a wheel that will fit as many different vehicles as possible, aftermarket wheel manufacturers usually machine the center bore to a larger size – and then use centering rings to create a tight, vehicle-specific fit. Don’t let universally-sized center bores deter you from ordering the wheels you like, because the use of centering rings to center a wheel on a vehicle’s flange has become standard in the aftermarket industry.

What the centering ring does is fill any empty space between the wheel hub and the center bore of the rim. It centers the wheel on the wheel hub, so that no wobbling or vibrations show up at speed. It goes without saying that a properly sized centering ring is crucial to vehicle safety, handling, and ride comfort.

Hub Centric vs. Lug Centric Wheels

Some wheels are not designed to center on the hub flange. These non-hub centric wheels are referred to as “lug centric”, because they are centered on the lug bolts or studs as the wheel hardware is gradually tightened. To reduce the risk of runout and vibration, lug centric wheels should never be tightened with the weight of the vehicle on the wheel.

Bolt Pattern

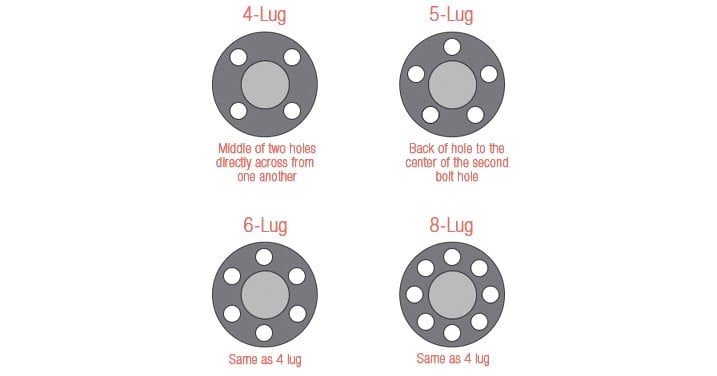

Wheels are secured to the hub with lug nuts that fasten to studs on the hub, or with lug bolts that thread into holes in the hub. There can be anywhere from 4 to 8 studs/holes on late model cars and light trucks. Unfortunately the numbers of studs or holes is not the only difference between vehicles, as the distance between the adjacent studs or holes can also vary. This is why a wheel with 5 holes will not fit every vehicle with 5 studs.

What Is A Bolt Pattern?

Bolt pattern is expressed as the number of studs or holes x the distance between 2 specified studs/holes. For example, the bolt pattern 5 x 4.5 means 5 studs/holes with 4.5" between the centers of the studs/holes opposite one another. (On a 5-lug hub, count the 2nd adjacent stud from your initial stud.) Bolt pattern can also be expressed in metric form, with 4 x 100mm signifying 4 studs/holes with 100 millimeters between the centers of the studs/holes opposite one another.

It's easy to measure the pattern on vehicles with 4, 6 or 8 studs/holes, just measure between the centers of the studs opposite each other. 5-lug patterns are more difficult, as measuring per the illustration may not give the exact dimension. All wheel manufacturers have the bolt pattern information for every vehicle they make wheels for, so as long as the make, model and year of vehicle is furnished, a wheel with the right pattern can be supplied.

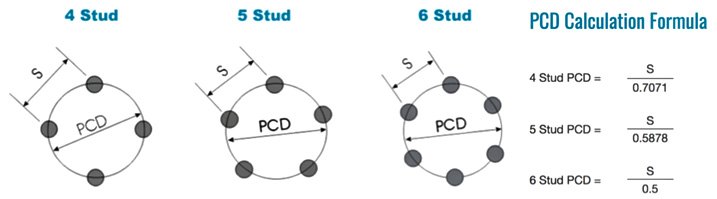

What Is Pitch Circle Diameter?

Another wheel measurement that’s sometimes used is pitch circle diameter (PCD). This is the diameter of an imaginary circle that passes through the center of all studs, lug bolts, or wheel rim holes.

Pitch circle diameter is calculated by taking a measurement between the center points of any two lug holes. Then, that measurement is divided by .7071 for a 4-stud wheel, by .5878 for a 5-stud wheel, or by .5 for a 6-stud wheel to arrive at the PCD.

Wheel Spacers And Adapters

What Are Spacers, And Why Might I Use Them?

If your wheels sit too far inboard (positive offset) or wider tires have created a rubbing situation against the inner wheel well liner or suspension components, wheel spacers are simple, round metal plates that correct these issues by mounting on a wheel hub assembly to relocate a wheel to a more outboard (negative offset) location.

Many drivers who use spacers like them because they create the look of wider rims and tires without the expense and effort of purchasing and fitting new parts. Wheel spacers are also helpful if you need extra clearance for big brake kits, coilover springs, or other suspension upgrades.

Since spacers are available in a variety of diameters and bolt patterns, we recommend entering your make, model, and year to let our website determine which spacer products are a match for your vehicle.

Once you know the diameter and bolt pattern is right for your vehicle, the next part is figuring out how thick you want your spacers to be. For more on how to figure out ideal spacer thickness, our related article The Trick Way To Determine What Size Wheel Spacer You Need will show you some easy tips.

What Are Adapters, And How Are They Different From Spacers?

Wheel adapters go a step further. Like wheel spacers, these mount on the wheel hub assembly to create a more negative offset. Adapters, however, allow you to change a vehicle’s bolt pattern. You might be able to change it from a 4-bolt to a 5-bolt setup, or from a 5-bolt to a 6-bolt pattern. This lets you to change to a wheel that has a different pitch circle diameter (see above).

Adapters allow you greater freedom of choice when it comes to selecting aftermarket custom wheels, because you’re not limited to those that match your OEM bolt pattern. Typically, longer bolts or studs will be included to ensure the wheel can be securely fastened.

What Are Disadvantages of Wheel Spacers and Adapters?

Even if you keep your existing factory wheels in place and don’t pursue plus-sizing, spacers and wheel adapters can have several drawbacks when used in an excessive amount of thickness.

By positioning your wheels significantly further out than vehicle engineers intended them to be, you can negatively affect the vehicle’s suspension geometry. When a wheel is positioned on the hub as designers intended, the load of the vehicle rests squarely and evenly on the wheel bearings positioned inside the hub. When a wheel sits further out, the angle of the load on the wheel bearings changes and becomes uneven. This can cause premature bearing failure. Alignment specs can be affected to the point of causing premature tire wear and greater steering difficulty.

TPMS Sensors With Your New Wheels & Tires

If you have a 2008 or later model year vehicle sold in the U.S., it was built with a tire pressure monitoring system (TPMS) by law. This system consists of an on-board computer which reads radio signals sent from tire stem sensors that mount on each wheel inside the tire.

If your vehicle is equipped with such a system, you’ll need to either transfer these sensors from your old wheels to the new ones, or purchase a new set of sensors. Without readings from all four tires, your vehicle will constantly annoy you with warnings about low pressure or an error in the system.

Rather than pay the cost to have your old tires dismounted to retrieve the old sensors, consider purchasing a new set of TPMS sensors with your new wheels. We say this because old ones don’t last forever - only until their built-in batteries wear out. Essentially, TPMS sensors are a wear item that need to be replaced sooner or later anyway.

Note: If you purchase wheels and tires together from CARiD in the same order, we’ll mount and balance them at no extra cost before shipping them to you. And since there’s no extra labor to install new TPMS sensors during this process, we’ll also perform their installation free. For this reason, you’ll see tire pressure sensors listed as an option within our wheel & tire drop-down menu. We've set up our website such that, if your vehicle is required to use TPMS sensors, they’ll be pre-selected on the order automatically (you can unselect them if you prefer).

We hope this article has clarified for you the all-important wheel specifications of diameter, width, backspacing, and more! Once you have an understanding of how these parameters affect wheel fitment, ordering the right rims and tires for your vehicle becomes much easier. Now, you can focus on the most important detail – style!