FREQUENTLY ASKED QUESTIONS

- EMISSIONS

- TROUBLESHOOTING

- AIR FILTERS

- CLEAN/SERVICE

- AIR INTAKE SYSTEMS

- CABIN AIR FILTERS

- EXHAUST SYSTEMS

- OIL FILTERS

- ARE K&N® PERFORMANCE AIR INTAKE SYSTEMS EMISSIONS LEGAL IN THE US?

-

- All intake systems are legal in most states because most states do not have regulations governing them. So this question really has to do with California and other states that have emission control standards. In order for an intake system to be legal in these states, it must receive an Exemption in the form of an EO number from the California Air Resources Board (CARB). To further complicate matters CARB exemption is issued only for specific part numbers used on specific vehicles. That means a part number can be CARB exempt for some vehicle applications and not others. There is no such thing as CARB Pending. A particular part number on a particular vehicle is either exempt or not. The best way for you to determine the status of the part number you are interested in for your vehicle is to look up the intake systems available for your vehicle in company vehicle/part search engine and check for CARB exemption. If you are unsure whether CARB exemption is required for a part to be legal in your state, check with your local or state motor vehicle or emissions agency.

- ARE K&N® FILTERS EMISSIONS LEGAL?

-

- All K&N direct replacement filters are emissions legal. They perform the same function as other types of disposable filters and fit right into the factory air box. K&Ns custom, universal or conical air filters are not legal for street use in California or other states that have emission control standards. However, if the intake system you are attaching a K&N cone filter to is CARB exempt, the K&N cone filter will not change that status and will be part of the exempt system. Check your local laws if you are unsure what modifications may be allowed on your vehicle.

- WHY IS THERE A PROPOSITION 65 WARNING ON MY PRODUCT BOX?

-

- Proposition 65 requires that businesses notify California residents regarding potentially harmful chemicals (those that may cause cancer or reproductive harm) that can be found in their products. These warnings are intended to help consumers make informed decisions regarding the safety of the products that they purchase. To learn more about Proposition 65, please visit the California Office of Environmental Health Hazard Assessment website.

- CAN A K&N® PRODUCT CAUSE A CHECK ENGINE LIGHT/SERVICE LIGHT TO COME ON?

-

- While uncommon, it is possible that a check engine light may come on after installing a K&N® air filter or performance intake system-but this does not necessarily mean that there is something wrong with your air filter or intake system. Occasionally, the increase in airflow and lower restriction provided by a K&N air filter or intake system will uncover an existing mechanical or electronic issue in a vehicle. In rare cases, you may have a K&N product which was manufactured outside of its design tolerances, causing sensors in your vehicle to read data outside of their normal expected values. Please contact customer service if you have any concerns regarding your vehicles performance after the installation of a K&N product.

- WILL A K&N® FILTER CAUSE MY VEHICLE'S MASS AIRFLOW SENSOR TO FAIL?

-

- An unsubstantiated claim has circulated saying that K&N® oiled air filters can cause mass airflow sensors to fail. K&N has thoroughly investigated this claim, and has found no evidence to suggest that K&N filter oil is able to cause MAF sensor damage. Over the past several years, K&N has compiled data regarding MAF sensors sent in by consumers and dealerships, which you can view here .

- CAN A K&N® AIR FILTER BE MADE AT THE FACTORY FOR ANY APPLICATION?

-

- With over 10,000 part numbers available, there is a very good chance K&N® has an existing product to meet your filtration needs. In the event we do not have an air filter available, you may look into the K&N Custom Filter Program.

- HOW CAN I TELL THE SIZE OF THE ENGINE IN MY VEHICLE?

-

- Most vehicles have an emissions decal placed either on the backside of the hood, on the radiator core support, or on the air box (the box that holds the air filter in place). Your engine size should be shown on the decal (4.0L for example). If you cant find the emissions decal you may also find the engine size printed on the decal under the hood that shows your engines belt routing. You may also write down your Vehicle Identification Number that is stamped visibly near your drivers side dashboard top and listed on your vehicle registration certificate. This number can then be entered on K&Ns part search by VIN webpage to find engine size as well as products for your vehicle. You may also contact your local dealership.

- HOW DO I FIND MY VEHICLE'S YEAR, MAKE, MODEL, AND ENGINE SIZE?

-

In North America, most vehicles have the model year and engine size printed on an emissions decal placed on the underside of the hood. Many vehicle manufacturers display make and model emblems on the back or side of the vehicle. If you know your make, model, year, and engine size, you can use K&Ns application search to locate compatible products for your vehicle.

Your vehicle identification number (VIN) can also be a quick and easy way to find compatible K&N® parts for your vehicle. Your vehicles VIN is printed on a tag located on the drivers side dashboard of your vehicle, and can be read from the outside looking in through the windshield. The VIN is also located on a tag inside the drivers side door jam or on the door itself. It is also listed on your vehicle registration certificate. If you know your vehicles VIN, you can use K&Ns vehicle search by VIN tool to find compatible products for your vehicle.

In Europe, your registration documents detail your engine size and vehicle type. However, if you do not know whether your vehicle is spi (single point injection) or mpi (multi point injection), Company suggest that you consult your local dealer. Once you have found your vehicles information, please use K&Ns vehicle search bar up above to find compatible K&N® products.

- HOW DO I FIND/CALCULATE THE PROPER FILTER SIZE FOR MY CUSTOM APPLICATION?

-

SHAPE

When fitting a conventional round filter on top of your engine-such as a carburetor, central fuel injector, or throttle body fuel injector-a large diameter, short filter will provide more airflow than a small diameter, tall filter. For example, a 10-inch diameter, 2-inch tall filter will provide more airflow than a 5-inch diameter, 4-inch tall filter. Where space permits, the height of the filter should be between 1/5 and 1/4 of its diameter.

The shape of the filter is less important if the application calls for a remote mounted filter, which includes many late-model fuel-injected vehicles. Typically, these vehicles will use a flat panel filter, or a conical/cylindrical shaped filter with a rubber mounting flange designed to be mounted on the end of the inlet hose.

SIZE

Use the formula below to compute the minimum size filter required for your particular application. The usable portion of the filter-the effective filtering area-is calculated by multiplying the diameter of the filter times pi (3.1416), multiplying by the height of the air filter in inches, and then subtracting .75-inch. Company subtract .75-inch to compensate for the rubber seals on each end of the element and the filter material near them, since very little air flows through this area.

If you are sizing a panel filter, multiply the width of the filter area (not the rubber seal) by its length. If you are sizing a round filter, use the following formula to determine the height of the filter.

Referencing the K&N vehicle search bar shows the proper filter for this application would be an E-1500, which is 3.5 inches tall. Keep in mind, this is the minimum size requirement. To provide an even greater volume of air to the engine, install the largest filter that will fit in the space allotted.

Off-road conditions require additional filter surface area. A filter should be sized 1-1/2 to 2 times larger than normal for any conditions that could be considered severe. In this case, the E-1500 used in their example should be replaced

- ARE K&N® HIGH-FLOW AIR FILTERS™ BETTER THAN DISPOSABLE PAPER FILTERS?

-

Typical disposable paper air filters function on a size-dependent basis, in which dirt particles that are larger than the openings in the filter media are blocked, while particles that are smaller than the openings can pass through. Most disposable paper filters create more airflow restriction than K&N filters, as the openings in the filter media have to be tiny in order to filter efficiently, which can reduce airflow.

K&N ® High-Flow Air Filters™ utilize depth loading, in which multiple layers of pleated cotton fibers provide particle retention on many levels. However, while most typical paper or foam filters would experience a large reduction in airflow when designed for a dramatic increase in efficiency, High-Flow Air Filters™ are specifically engineered to capture dirt while still allowing a high volume of airflow to pass through.

- WHY IS AIRFLOW CRITICAL TO ENGINE PERFORMANCE?

-

- Under normal circumstances, an increase in airflow to the engine also increases the efficiency of the combustion process, which can result in an increase in horsepower. K&N® High-Flow Air Filters™ are designed to provide high airflow in order to help increase engine performance.

- WHAT'S THE DIFFERENCE BETWEEN K&N® FILTERS AND OTHER FILTERS THAT LOOK SIMILAR?

-

- Both airflow and filtration efficiency are critical to engine performance. Some companies design filters that provide high airflow by greatly reducing filtration efficiency, which can risk engine damage. K&N® filters are designed to provide high airflow while also maintaining exceptional filtration. As the appearance of K&N filters has become popular, many companies have started offering products that mimic the appearance of K&N filters, but do not provide the same level of quality and protection.

- WHAT IS THE MICRON RATING AND EFFICIENCY OF A K&N® AIR FILTER?

-

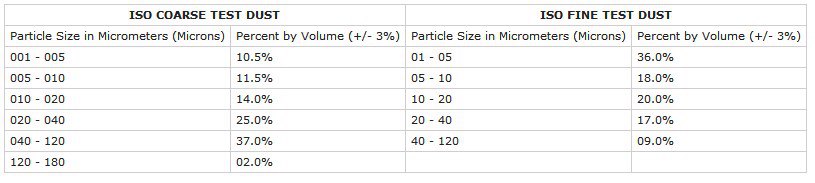

- Air filters are not measured by micron size. As an industry standard, air filters are tested in accordance with the ISO 5011 test protocol to measure capacity (the physical amount of dust a filter can hold before cleaning is necessary) and efficiency (the filters ability to trap and hold dust). See technical service bulletin 89-5R from the Filter Manufacturers Council. The dust selected for the test contains a specified distribution of different particle sizes according to ISO standards.

As has become customary in the automotive industry, we use Coarse Test Dust for gasoline engine air filters and Fine Test Dust for diesel engine air filters. This practice of using different grades of test dust developed because Diesel engines require higher levels of filtration because they operate at much higher compression and require tighter tolerances than Gasoline engines.

Their testing has demonstrated that on average, K&N replacement air filters and air intake systems have a cumulative or Full Life filtration efficiency of between 96% and 99%. Different filters test at different efficiencies due to changes in their shape, surface area and relationship to the direction of air flow through the factory air box or test housing. Like most air filters available in the USA, our filters will provide all the engine protection you need.

- HOW EFFICIENT ARE K&N® FILTERS AT TRAPPING CONTAMINANTS?

-

- Laboratory tests utilizing ISO 5011 test protocols demonstrate that most K&N® air filters achieve overall filtration efficiency in the range of 97% to 99%. (The ability of an air filter to protect an engine is generally measured in accordance with laboratory testing procedure ISO 5011.) K&N® air filter designs are subjected to ISO 5011 testing involving coarse and fine test dust, and the test results are measured by a specific air filtration efficiency number. K&N® filters are designed to provide exceptional airflow while simultaneously targeting an overall filtration efficiency that meets or exceeds OEM standards.

- DOES INCREASED AIRFLOW MEAN THAT MORE DIRT WILL GET THROUGH THE FILTER?

-

- No. Most disposable filters are "barrier filters" which act as a physical barrier to dust particles. Once a dust particle covers a pore in the media, air can no longer flow through that space. K&N® replacement air filters are designed to absorb dirt and dust particles instead of physically blocking them, allowing the pores in the material to continue flowing air.

- WHAT ARE THE FILTRATION REQUIREMENTS FOR MY VEHICLE?

-

- Most vehicles do not have a published minimum filtration requirement, as filtration needs will vary greatly among vehicles based on usage and other factors. However, K&N® filters are engineered to meet or exceed OEM standards.

- HOW WILL A K&N® FILTER AFFECT MY VEHICLE'S FUEL ECONOMY?

-

- K&N® does not make any claims or advertisements regarding fuel economy.

- WHAT INCREASE IN HORSEPOWER SHOULD I EXPECT FROM A K&N® REPLACEMENT FILTER?

-

- K&N® does not complete vehicle performance tests (dynamometer tests) for every application for which a replacement air filter is offered. Airflow testing is performed on every air filter design in order to verify that the K&N filter provides high airflow. However, other components of the vehicles air intake system (like the air filter housing or tubing) can create air restriction and limit horsepower. The design of these parts varies among different vehicles and manufacturers, so there is no way to accurately estimate a specific horsepower gain from replacing an air filter alone.

- ARE K&N® AIR FILTERS BETTER FOR THE ENVIRONMENT?

-

- K&N® High-Flow Air Filters™ are designed to last for the life of your vehicle. If you assume an engine life of 175,000 miles-and replace your disposable air filter every 15,000 miles-only one K&N air filter will be used during the same period in which eleven disposable air filters are discarded.

- WHAT IS THE DIFFERENCE BETWEEN A DRYFLOW® AIR FILTER AND A HIGH-FLOW AIR FILTER™?

-

- While the oiled K&N® High-Flow Air Filter™ continues to be the most popular filter type among K&N® filter products, K&N also offers non-oiled synthetic DRYFLOW® air filters. The DRYFLOW® filter media is composed of two-layered synthetic material, which-much like High-Flow Air Filter™ media-provides depth loading properties. DRYFLOW® filter media provides slightly less airflow than High-Flow Air Filter™ media, though it is still designed to strike a desirable balance between airflow and efficiency, provide a high level of contaminant capture, and outperform typical disposable paper air filters in airflow. Because they do not have to be re-oiled, servicing DRYFLOW® air filters is typically a quick and easy process.

- WILL USING A K&N® REPLACEMENT AIR FILTER VOID MY FACTORY WARRANTY?

-

- No. In the United States, in order for the manufacturer of a warranted product to void or deny warranty coverage of a repair due to the use of an aftermarket part, the manufacturer must provide proof that the aftermarket part is the cause of the necessary repair. These rights are protected under the Consumer Products Warranty Act of 1975 (also referred to as the Magnuson-Moss Warranty Act).

- SOME AIR FILTER COMPANIES TOUT THEIR HIGH FILTRATION LEVELS IN THE 99TH PERCENTILE. DOESN'T HIGHER FILTRATION MEAN A BETTER AIR FILTER?

-

No. The quality of an air filter can only be judged by reviewing all four important characteristics. 1) Restriction while loading with dust; 2) Filtration efficiency as a percentage; 3) Dust holding capacity before the filter needs cleaning or replacement ; and 4) filter life. Any company designing an air filter must make choices about these four characteristics and how their filter will perform in each area. Generally speaking, each characteristic of an air filter has an inverse relationship to at least one of the others, meaning, as filtration efficiency goes up, restriction increases and capacity or service life decreases. So an air filter manufacturer can design an air filter to have ultra high filtration efficiency by compromising the filters restriction, capacity, and/or service life. They judge the quality of an air filter based upon the proper balance of these four essential criteria. Maximizing one at the expense of others sounds more like a marketing goal rather than an engineering goal. So the basic answer to the original question is that higher filtration is not necessarily a good thing when it comes at the expense of restriction, reusability and/or capacity. While the benefits of a filter with 99.9% filtration are unknown, the benefits of low restriction are measurable and clear. Low restriction helps an engine perform more efficiently generating more power and torque.

That would lead a reasonable person to ask what then is a safe level of filtration. This question is literally unanswered. Minimum air filter specifications are generally not called out in vehicle owners manuals, nor will you find much published information on air filtration requirements from vehicle manufacturers. They have never seen a scientific study concluding what levels of filtration efficiency correspond to various levels of engine wear. Some large air filter companies do not even publish information on the efficiencies of the air filters they manufacture. It is KNNs opinion that both the Fine and Coarse Test Dust mixtures used in air filter testing contain such a high concentration of small particles that even filtration efficiency numbers as low as 90% may provide adequate engine protection. Remember that almost 11% of COARSE test dust is smaller than 5.5 microns (the size of a red blood cell).

The fact is that an engine is not a pristine environment. Fuel enters after passing through a fuel filter, combines with air which is ignited to explode in a pressurized chamber. The combustion is not 100% efficient and leaves residues behind that must be flushed from the engine. Engines have tolerances or measured gaps between surface areas. While there are few if any studies on engine wear, it would seem reasonable to speculate that particles less than 5.5 microns create little engine wear unless ingested at very high levels of concentration. As support for this theory, consider the filtration levels provided by fuel filters and oil filters that sometimes tout their ability to filter particles above 10 or 20 microns.

If you really want to compare two air filters, you need to know all four characteristics mentioned above. Consumers can then choose what matters most to them. But comparing two air filters with only one piece of information is like saying a bicycle is better than a car based solely on a comparison of mileage. Yes the mileage is better, but a car has a few other benefits (speed, comfort, keeps you dry in wet weather) that just may offset the mileage disadvantage.

They design air filters to provide low restriction throughout the filters service interval. They seek the best balance between airflow and filtration recognizing they are inversely related. After nearly 40 years in business with millions of air filters sold, they have a track record you can trust and the experience that can only be earned through years of focusing on just one thing. But even their experience is not enough. They operate a fully staffed air filtration lab that operates on a year round basis with two test stands. The lab was designed by Southwest Research and is calibrated regularly to ensure their test results are reliable. This testing is an essential ingredient in verifying their air filters meet their own high standards of excellence. Making a great air filter is no accident and they are confident their air filters provide outstanding engine protection with huge air flow advantages throughout the air filters service interval. Thats why they back up their replacement air filters with both a Million Mile Warranty and their Consumer Protection Pledge.

K&Ns air filtration lab tests air filters according to ISO5011 test protocol. The ISO (International Organization for Standardization) is an international organization which establishes standards used by different industries worldwide. The ISO does not establish any standards for an air filters effectiveness; they establish standards for the testing procedures used to find air filters capacities and efficiencies only under the fixed and chosen parameters of the test being conducted. In the case of engine air filters, the ISO5011 test ensures consistency in the procedure used to test a filters initial restriction, initial efficiency, cumulative (full-life) efficiency, and dust holding capacity. Using a standardized test procedure and disclosing the user selected variables ensures the same test can be run anywhere around the world. Some of the requirements of the ISO5011 test procedure are that the temperature of the test lab must be maintained at 23 degrees Celsius +/- 5 degrees Celsius, and the relative humidity of the test lab must be maintained at 55% +/- 15%, for the entire duration of the test. During the test at each weighing stage (when the mass of the filter is found) the humidity can only vary +/- 2%. Also, all test dust which is fed into the air filter must be "found" after the test is completed. That means if 10 grams of test dust is fed to the filter during the test, but only 8 grams of dust is found trapped in the filter after the test, part of the ISO5011 test procedure requires that the remaining 2 grams of dust must be found. The dust could be in the air filter housing, the air duct, or the absolute filter which traps any dust that passes through the air filter, but wherever it is it must be accounted for. If any of the requirements of the ISO test procedure are not met, the test is not valid. A companys participation in testing using ISO5011 test procedures is strictly voluntary. Conducting an ISO5011 test requires a considerable investment in both time and equipment, and many air filter companies simply do not have the resources to complete an ISO test in-house. K&N views this test procedure as a valuable part of their research and development process.

- WHAT ARE THE AIR FILTRATION REQUIREMENTS FOR MY VEHICLE?

-

- There is no published requirement for vehicle filtration. Car and truck owners manuals are silent on the issue and you will find very few companies that even credibly discuss filtration efficiency. Company believe this demonstrates that most air filters sold today provide adequate levels of filtration. Particularly when compared with the filtration provided by fuel and oil filters.

- CAN A K&N FILTER GIVE MY ENGINE TOO MUCH AIR FLOW?

-

- No. An engine can only draw in a certain volume of air depending on the engines size (measured by such things as bore, stroke and number of cylinders). Vehicles are designed to accommodate large changes in air pressure so they can operate at sea level or at an altitude of 14,000 feet. Engine computers adjust the amount of fuel required as a result of changes in air pressure (density). Air filter restriction when the filter is new and especially as the filter loads with dust will result in lower air pressure and availability similar to being at a high elevation. High-flow air filters that were invented by K&N were designed to reduce the work necessary to pull air through the filter and to increase air pressure. Increased air pressure is one of the key elements in producing more power.

- MY FILTER CAME WITH A TUBE OF SEALING GREASE. HOW IMPORTANT IS IT?

-

- It is rather important. It helps to maintain a seal on an uneven air box surface. If sealing grease is unavailable, white lithium or synthetic grease will work just fine. Petroleum-based products are not recommended.

- HOW WILL A K&N® FILTER AFFECT MY VEHICLE'S FUEL ECONOMY?

-

There is a relationship between air filter restriction and mileage. The theory behind this is simple, the harder an engine has to work to suck air through the intake tubes and air filter, the more gas gets wasted in the process. Many K&N users report an increase in their fuel economy after beginning to use K&N air filters. However, these experiences do not mean you will also experience a change in your mileage. Company certainly understand why it is theoretically possible for a consumer to experience a mileage increase after installing a K&N air filter or intake system, however, they do not go so far as to make a general claim that K&N air filters and intake systems will provide an increase in mileage.

It is virtually impossible to make sweeping and general claims about mileage. Even the EPA fuel rating numbers for new cars are often not representative of the mileage you actually experience. There are many variables that affect mileage such as: tire inflation, the type of fuel, weather, elevation, the speed at which you drive, the gear in which you drive, the speed with which you accelerate, engine maintenance, excessive idling, cruise control, the grade of motor oil you use, and of course, the condition of your air filter. In short, mileage is complicated.

K&N filters are less restrictive than disposable paper or synthetic air filters and K&N Intake Systems are less restrictive than the factory installed air path. So K&N filter technology could be an important tool, when combined with other elements, to help keep mileage as high as possible.

Oh yeah, theres one more limitation imposed by science. If you take advantage of added power by driving more aggressively, you will reduce mileage. You cannot have your cake and eat it too.

- SHOULD I INSTALL THE LARGEST K&N FILTER THAT WILL FIT IN MY RACE VEHICLE?

-

- If an existing KNN filter is large enough to provide negligible restriction, a larger than required filter will not affect the amount of air an engine can take in, however, it will lengthen the filters service interval. A longer service interval can be an important factor when racing in dusty, dirty environments.

- WILL A K&N FILTER CAUSE MY VEHICLE'S MASS AIR SENSOR TO FAIL?

-

No, it is both impossible and ridiculous.

It is impossible because they know that the oil treatment on their cotton is very small (usually less than 2 ounces). Once the oil is properly and evenly absorbed through the cotton, no oil will come off, even under extreme engine conditions. It is ridiculous, because no dealership or service provider has ever been able to provide us with evidence to support this "myth," and in fact, their investigations have revealed that even authorized dealerships are simply speculating and do not have the test equipment necessary to know whether the sensor has failed or why. It is even more ridiculous because some car manufacturers use and sell air filters treated with oil on a regular basis. There are also major brands of disposable air filters that are treated with oil. They all use oil for the same reason, it helps in the filtration efficiency of an air filter.

Out of the millions of air filters we sell, they only receive a handful of consumer complaints each month that a dealership or service provider has blamed a vehicle sensor repair on their product. They take each complaint very seriously and see it as an opportunity to stop a consumer from being taken advantage of.

As a result of their standing up for consumer rights and providing assistance to resolve a disagreement, they have had over 100 actual sensors sent to us by dealerships who claimed their product had caused them to fail. Microscopic, electronic and chemical testing revealed that none of the sensors were contaminated by K&N oil. What is perhaps the single biggest clue to what is going on is that over 50% of these sensors were not broken in the first place for any reason.

- MORE AIRFLOW MEANS YOU ARE LETTING MORE DIRT THROUGH, RIGHT?

-

- No. Filtration testing measures the percentage of dust retained before the filter reaches a terminal test pressure, often 10" of restriction above initial restriction. We use airflow as a simplified term to explain a more complicated physical process. The more precise description is restriction: K&N air filters create less restriction which helps an engine run better. An engine will only use the air it needs and company air filters do not result in an engine using more air than necessary. Rather, they result in the engine experiencing less restriction. The terms airflow and restriction are inversely related. Their air filters provide either less restriction at a fixed airflow rate; or more airflow as a fixed level of restriction. In neither case is more air being used than necessary.

- HOW OFTEN DO I NEED TO CLEAN MY K&N® AIR FILTER?

-

- If you have not experienced a decrease in mileage or engine performance, chances are your filter is fine and does not yet need cleaning. To be more specific, the filter does not require cleaning if you can still see the wire screen on the entire air filter regardless of how dirty it may appear. When the screen is no longer visible some place on the filter, it is time to clean it. When used in normal paved road, street or highway conditions, K&N replacement air filters that fit in the factory air box should require cleaning every 50,000 miles and K&N large conical filters on an intake system should require cleaning every 100,000 miles. When used in dusty or off-road environments, K&N filters will require cleaning more often. Company recommend that you visually inspect your filter once every 25,000 miles to determine if the screen is still visible.

- HOW MANY TIMES CAN I WASH AND REUSE MY K&N® HIGH-FLOW AIR FILTER™?

-

- K&N® High-Flow Air Filters™ can be cleaned and re-oiled using a K&N Recharger® kit as often as is reasonably necessary. K&N drop-in replacement High-Flow Air Filters™ typically require servicing once every 50,000 miles under normal highway driving conditions, and the larger filters included with K&N intake systems can go up to 100,000 miles before needing to be cleaned (under normal highway driving conditions). Follow this link to view complete cleaning instructions.

- HOW DO I CLEAN MY K&N® DRYFLOW® AIR FILTER?

-

- Once you determine your K&N® DRYFLOW® air filter needs to be cleaned, K&N® air filter cleaning products help restore your air filter to like-new condition. There are specific cleaning kits available for non-oiled K&N filters. Follow this link to view complete cleaning instructions and available products.

- IS IT POSSIBLE TO OVER-OIL A HIGH-FLOW AIR FILTER™?

-

- When servicing your High-Flow Air Filter™, be sure to follow the re-oiling directions carefully. Use only K &N oil, and never saturate the filter. If oil drips from the filter, allow the filter to sit for several minutes until it stops dripping, and then wipe any excess oil from the filter frame. Follow the oiling instructions included in the Recharger® cleaning kit, and contact customer service if you have questions regarding the oiling process. For the required oil quantity by filter part number, enter the part number in the "Search by Part" box on our Application Search Page, and the factory oil amount will be shown.

- DO K&N® AIR FILTERS COME PRE-OILED OR MUST THEY BE OILED BEFORE USE?

-

- Most K&N® cotton air filters come from the factory pre-oiled and ready to install. Certain specialty and racing filters are manufactured as un-oiled filters, and will be clearly indicated as such. Synthetic air filters (such as DRYFLOW® air filters) do not utilize filter oil. Please refer to the Product Specifications on the product details page for your air filter to determine if oil is required, or contact customer service.

- CAN I USE ANYTHING OTHER THAN K&N® CLEANER AND OIL?

-

- K&N® does not recommend using other detergents or solvents to clean your air filter, and does not recommend applying any other type of oil. Products other than those manufactured by K&N® have not been tested and may deteriorate the performance and filtering ability of your air filter. Follow this link to view K&N® cleaning product options.

- For best results, they recommend that you use K&N® air filter oil and K&N® air filter cleaner. K&N® air filter oil is a special compound which forms a very efficient tacking agent that helps capture dust. Company cleaner is a non-detergent degreaser. Petroleum products such as transmission fluid and motor oil will soften and destroy the rubber sealing edges. Harsh solvents and gasoline will harden the rubber seals causing the filter to distort (shrink). A mild detergent can be used in a pinch, but care should be taken to fully rinse it out. Rinsing detergent out of a filter is similar to getting soap out of a sponge; its not that easy to do. Always make sure the filter is dry before re-oiling.

- CAN I USE COMPRESSED AIR TO DRY MY K&N® FILTER FASTER?

-

- No, this can blow the filter material right out of the wire mesh and ruin the filter. Pick a nice day to clean the filter and let it dry naturally. A low pressure air flow such as from an industrial drying machine or blow dryer will help the filter dry more quickly.

- K&N® recommends against using compressed air to dry your air filter, as compressed air may rip and tear the filter fibers. Always allow the filter to dry naturally.

- CAN I USE A BRUSH TO HELP DISLODGE DIRT ON MY FILTER BEFORE CLEANING?

-

- K&N® does not recommend the use of brushes to clean air filters, as the bristles from a brush may rip and degrade the filter media.

- HOW MUCH OIL SHOULD I USE TO RE-OIL MY FILTER AFTER IT IS CLEANED?

-

- The best way to ensure proper oiling is to use squeeze bottle Recharger® kit. With a squeeze bottle, you simply run a bead along the top of each pleat on both sides of the filter. If using an aerosol Recharger® kit, make one light pass over the entire filter area front and back. The oil will then be evenly absorbed throughout the rest of the cotton medium over the next several minutes. Company recommend you let your filter set for 1 hour to let any excess oil run off the filter. In any event, you do not need to worry about over oiling your filter and you should make sure the oil appears fully absorbed before re-installation.

- HOW DO I CLEAN A K&N AIR FILTER?

-

- Use a K&N Filter Care Service Kit, available at all major auto parts stores and a low pressure nozzle-free garden hose. A filter cleaned with K&N cleaning products will ensure a lifetime of performance from your air filter. Instructions for cleaning your K&N air filter are on our Air Filter Cleaning Instructions page.

- SHOULD I BRUSH THE WIRE SCREEN WITH A TOOTHBRUSH TO GET ALL THE "CRUD" OFF?

-

- No, this could tear up the cotton gauze.

- WHAT INCREASE IN HORSEPOWER SHOULD I EXPECT FROM A K&N® AIR INTAKE SYSTEM?

-

- K&N offers a guaranteed increase in horsepower and torque for all K&N intake systems. Dynamometer tests indicating estimated horsepower and torque increases compared to the OEM intake system will appear on the "Product Details" page for each performance intake system. Results will vary.

- K&N® provides estimated SAE corrected horsepower gains that are based on actual dynamometer testing for a specific or similar vehicle. The actual horsepower increase a consumer will receive will vary depending on such things as vehicle condition, fuel, weather, and other circumstances. It would be impractical to test every possible vehicle configuration or year in which a particular engine may be used; therefore, many of our estimates are based upon similar engine/vehicle/year dynamometer testing that we believe to be representational for the vehicle listed.

- WILL USING A K&N® REPLACEMENT AIR INTAKE SYSTEM VOID MY FACTORY WARRANTY?

-

- No. In the United States, in order for the manufacturer of a warranted product to void or deny warranty coverage of a repair due to the use of an aftermarket part, the manufacturer must provide proof that the aftermarket part is the cause of the necessary repair. These rights are protected under the Consumer Products Warranty Act of 1975 (also referred to as the Magnuson-Moss Warranty Act).

- WHAT DOES A COLD AIR INTAKE DO FOR A CAR?

-

- K&N® cold air intake systems allow for increased airflow to your engine, which results in an increase in horsepower and torque.

- IS A K&N® PERFORMANCE AIR INTAKE SYSTEM BETTER THAN A STOCK SYSTEM?

-

- K&N® performance air intake systems are designed to create a less restrictive path for airflow to reach the engine by removing the stock intake tubing that can increase restriction, and also by utilizing high airflow filter media.

In a K&N cold air intake system, air first passes through a performance air filter-typically a High-Flow Air Filter™, which is designed to provide up to 50% more airflow than a disposable paper filter-and then passes through a specially designed tubing system that helps provide a smooth path for airflow.

- K&N® performance air intake systems are designed to create a less restrictive path for airflow to reach the engine by removing the stock intake tubing that can increase restriction, and also by utilizing high airflow filter media.

- WHICH K&N® INTAKE SYSTEM SHOULD I CHOOSE?

-

- K&N offers several intake system options to cater to different aesthetic, ease of maintenance, and filter media preferences. All are protected by K&Ns famous 10-Year/Million Mile Limited Warranty.

Roto-Molded High-Density Polyethylene (HDPE) Intake Systems: 57-Series, 63-Series

- High-density polyethylene (HDPE) rotationally molded tubes help increase the volume of airflow to your engine, and provide a guaranteed increase in horsepower and torque. These systems are paired with a washable, reusable High-Flow Air Filter™ featuring oiled cotton filter media, and the oversized, conical design allows you to go up to 100,000 miles between filter services under normal highway driving conditions. A custom heat shield or air box helps protect intake air from the high temperature of your engine bay, and the entire system can typically be installed in less than 90 minutes.

*Certain 57-series and 63-series intakes are designed to function with the factory air box, and feature a panel filter paired with a custom roto-molded intake tube.

Mandrel-Bent Aluminum Intake Systems: 69-Series, 77-Series

- Mandrel-bent aluminum intake tubes help provide an increase in airflow to your engine, and each 69-series and 77-series intake system offers a guaranteed increase in horsepower and torque. These systems are paired with a washable, reusable High-Flow Air Filter™ featuring oiled cotton filter media, and the oversized, conical design allows you to go up to 100,000 miles between filter services under normal highway driving conditions. A steel heat shield helps protect intake air from the high temperature of your engine bay, and the system can typically be installed in less than 90 minutes.

- Blackhawk Induction™ Air Intake Systems: 71-Series Blackhawk Induction™ air intake systems feature an oil-free synthetic filter media, black powder-coated aluminum intake tube, and all-black components. The layered DRYFLOW® synthetic filtration media provides increased airflow and exceptional engine protection without requiring oil, and a steel heat shield helps protect intake air from the high temperatures of your engine bay. The system can typically be installed in less than 90 minutes.

- CAN COLD AIR INTAKES IMPROVE GAS MILEAGE?

-

- K&N® does not make any claims or guarantees in terms of increased gas mileage with the use of K&N filters or intakes, due to a vast number of variables that can affect a vehicles gas mileage.

- HOW DOES AN ENGINE MAKE POWER?

-

- An internal combustion engine operates by burning a mixture of fuel and oxygen within the engines cylinders. The fuel injectors provide a precise amount of fuel, which combines with air delivered by the air intake system. A spark plug then ignites the volatile gas, creating an explosion that forces the piston downward-turning the crankshaft. The piston-moving force thats created during the combustion cycle is what produces horsepower. K&N performance products are designed to increase the efficiency of your engines combustion process.

- HOW DO I CLEAN THE FILTER INCLUDED WITH MY K&N® INTAKE SYSTEM?

-

- Once you determine that the filter included in your intake kit needs to be cleaned, K&N® air filter cleaning products help restore your air filter to like-new condition. There are specific cleaning products for each type of filter. Follow this link to view complete cleaning instructions and available products.

- WHY IS AIRFLOW SO IMPORTANT FOR MY ENGINE'S PERFORMANCE?

-

- Maintaining the proper air-to-fuel ratio (AFR) is critical for engine performance, and relates to the amount of air versus the amount of fuel used by an engine for combustion. A correct, stoichiometrically balanced AFR produces combustion with perfect efficiency, excluding other factors. For gasoline engines, the theoretically perfect chemical ratio is 14.7 : 1-14.7 parts air to one part fuel. In effect, this means that an engine requires almost fifteen times more air than fuel for efficient combustion-which emphasizes the importance of providing a high volume of air through an intake system.

- CAN I INSTALL A K&N® AIR INTAKE SYSTEM ON A VEHICLE WITH A BODY LIFT?

-

- K&N® intake systems are not compatible with vehicles equipped with a body lift. A body lift will raise the body and fenders of the vehicle above the engine and frame, and since most K&N intake kits mount to both the engine and the fender, the lift would move the mounting points needed to install the kit-possibly resulting in the tube coming loose, coming into contact with the hood or other engine components, and even breaking. In most cases, serious modifications would be required to make the kit work, and such modifications would void the 10-Year/Million Mile Limited Warranty.

*K&N intake systems are compatible with vehicles with a suspension lift installed.

- CAN I INSTALL A K&N® AIR INTAKE SYSTEM ON A VEHICLE THAT HAS A THROTTLE BODY SPACER?

-

- At this time, it is not recommended to install a K&N® intake system on a vehicle with a throttle body spacer. A throttle body spacer will move the opening of the throttle body away from its stock location. Since K&N develops intake kits on vehicles with a throttle body in the factory location, the addition of a spacer would add length to the intake tube, pushing it away from its mounting points-and possibly causing the tube to come loose, come into contact with the hood or other engine components, or even break. In most cases, serious modifications would be required to make the kit work, and such modifications would void the 10-Year/Million Mile Limited Warranty.

- WILL INSTALLING A K&N PERFORMANCE INTAKE SYSTEM VOID MY FACTORY WARRANTY?

-

- Most KN air intake systems are warranted for 1,000,000 miles which exceeds the warranty offered on the original factory intake system.

- The installation of an air intake system should not void your factory warranty. It is never a bad idea to contact your local dealership and ask them before purchasing the new K&N system whether they will object. If they tell you an air intake system will void your vehicle warranty, please contact us and they will speak with the dealership directly to clear up the misunderstanding. Another idea would be to contact a different dealer who may have a different policy since many dealership actually sell K&N intake systems.

- HOW DO I KNOW IF MY CAR HAS A CABIN AIR FILTER?

-

- Cabin air filters have become increasingly more popular, but some vehicles do not have cabin filters, so you will need to check your owners manual to determine if your vehicle has one.

- WHAT IS A CABIN AIR FILTER FOR?

-

- Cabin air filters are used to filter the air that is coming through your vehicles HVAC system and into the interior.

- IS THERE A DIFFERENCE BETWEEN A CABIN AIR FILTER AND A REGULAR AIR FILTER?

-

- Yes. Modern vehicles are sold with an air filter in the engine bay used to protect the engine from contaminants, and some have the addition of a cabin air filter used to filter the air entering your vehicles interior. While both types of filters trap contaminants, they are composed of different types of filter media and are not interchangeable.

- CAN I USE ANYTHING OTHER THAN K&N® CLEANER AND REFRESHER?

-

- K&N® does not recommend using other detergents or solvents to clean your K&N cabin air filter, as doing so may damage the filter media.

- DO K&N® CABIN AIR FILTERS COME PRE-TREATED OR MUST THEY BE TREATED BEFORE USE?

-

- Your K&N® cabin filter is sold pre-treated and ready to install.

- WHY IS AIRFLOW CRITICAL TO MY CAR'S HVAC SYSTEM EFFICIENCY?

-

- Installing a high airflow filter may help reduce HVAC system strain, which can help preserve your heating/cooling systems efficiency. Using a dirty or restrictive cabin air filter may put additional strain on your system.

- WHAT DOES A K&N® EXHAUST SYSTEM DO?

-

- K&N® exhaust systems are engineered to increase horsepower and torque, and provide a more aggressive engine sound.

- WHAT ARE K&N® EXHAUST SYSTEMS MADE OF?

-

- K&N® exhaust systems are composed of 304 stainless steel tubing. Some applications incorporate a polished stainless steel tip.

- HOW LONG DOES IT TAKE TO INSTALL A K&N® EXHAUST SYSTEM?

-

- K&N® exhaust systems can typically be installed in less than 60 minutes utilizing factory mounting points, with no welding required.

- ARE K&N® EXHAUST SYSTEMS AVAILABLE IN CAT-BACK OR AXLE-BACK CONFIGURATIONS?

-

- K&N® exhaust systems are available in both cat-back and axle-back configurations depending on the vehicle application.

- ARE K&N® EXHAUST SYSTEMS COMPATIBLE WITH OTHER UPGRADES?

-

- Yes. K&N® exhaust systems pair with most aftermarket modifications, including intake systems, boost control modules, throttle control modules, and more.

- WHAT POWER INCREASE DOES A K&N® EXHAUST SYSTEM PROVIDE?

-

- Dynamometer tests indicating estimated horsepower and torque increases compared to the OEM intake system will appear on the "Product Details" page for each performance exhaust system. Results will vary.

- K&N ® provides estimated SAE corrected horsepower gains that are based on actual dynamometer testing for a specific or similar vehicle. The actual horsepower increase a consumer will receive will vary depending on such things as vehicle condition, fuel, weather, and other circumstances. It would be impractical to test every possible vehicle configuration or year in which a particular engine may be used; therefore, many of our estimates are based upon similar engine/vehicle/year dynamometer testing that we believe to be representational for the vehicle listed.

- WHAT IS THE WARRANTY ON K&N® EXHAUST SYSTEMS?

-

- K&N® exhaust systems are protected by K&Ns 1-Year Limited Warranty.

- WILL A K&N® EXHAUST SYSTEM MAKE MY EXHAUST LOUDER?

-

- K&N® exhaust systems are engineered to improve the quality ("growl") of the engine sound, while not significantly increasing decibel output.

- CAN I USE CONVENTIONAL, SYNTHETIC, OR BLENDED OILS WITH MY K&N® OIL FILTER?

-

- Yes. K&N® oil filters are compatible with conventional, synthetic, and blended motor oils.

- WHAT IS THE EFFICIENCY RATING OF A K&N® OIL FILTER?

-

- Each K&N® oil filter is designed to meet or exceed OEM specifications for efficiency, and each design is laboratory tested for efficiency, capacity, and burst strength.

- HOW MANY MILES CAN K&N® OIL FILTERS BE USED BEFORE REPLACEMENT?

-

- K&N® oil filters are designed to withstand the longer service intervals that some vehicle manufacturers now recommend. Please follow your vehicle manufacturers recommendations for oil filter replacement.

- CAN THE NUT ON WRENCH-OFF® OIL FILTERS BE USED FOR INSTALLATION?

-

- No, the nut on Wrench-Off® oil filters cannot be used for installation, as doing so may cause serious damage to the filter. If you attempt to use the nut to tighten the filter on installation, you may end up over-tightening the filter or causing damage to the spot welds on the filter-which could result in cracking and leakage while the filter is in service. The nut is intended to be used for convenient removal only.