Frequently Asked Questions

- Wiper Blades

- Spark Plugs

- Oil Filters

- Brake Pads

- Oxygen Sensors

- Glow Plugs

- Starters & Alternators

- Wires

- How often should wipers be changed?

-

Wipers should be changed when they no longer perform as expected, or no longer provide a high enough level of safety. The recommended replacement interval for preventative maintenance is 6 months. Bosch's exclusive dual-rubber technology can extend this interval to as much as 12 months, and Bosch ICON wipers last an average 40% longer.

- What is dual-rubber technology?

-

Bosch ICON and Excel+ are the only wiper blades on the market that use this technology. The dual-rubber wiping element uses two different rubber formulations in the two areas which perform different tasks. For the wiping edge, that touches the windshield, a harder, more wear-resistant rubber is used than for the area that is responsible for making the wiping lip flip over properly when the direction of the wiper is reversed. This flip-over function is best provided by a softer, more flexible rubber. The two rubber types in combination result in better, lower-noise performance over a longer service life.

- What are the signs of a worn wiper blade?

-

There are various indications for worn-out wipers; streaks, smears, unwiped areas on the windshield; chattering, skipping wiper blades; nicked, cracked or separated rubber elements; noisy wiping action due to worn-out wiper blade joints.

- Do I need to replace wipers even if I rarely use them?

-

Wiper blades are important safety items even in the occasional rain shower. In dry climates, the rubber wiper elements are often subject to the aging effects of UV rays in sunlight and from heat. Dust, sand and other contaminants on the windshield can be damaging to the rubber wiping edge. Rubber formulations used by Bosch are highly resistant to these aging effects, but all blades need to be replaced eventually.

- Should I replace the wiper blades or just the refills?

-

A wiper blade consists of the rubber wiping element and the superstructure with brackets and joints that distribute the arm pressure and give the blade its flexibility. A refill is just the rubber element and one or two tension springs inside the rubber element or on its outside.

Replacing just the refill is a low-cost alternative to changing the wiper blade. Changing the complete blade is typically much easier and faster than identifying and finding the proper refill and removing and replacing the old. Replacing a complete Bosch Wiper Blade is a quick and easy process due to the exclusive DirectConnect™ installation system used for most vehicle applications.

Replacing the refill too many times should be avoided as the wiper blade superstructure will wear out over time as well.

- Is it sufficient to replace the driver's side wiper?

-

It is recommended to replace the driver's side and passenger's side wipers at the same time for improved vision and increased safety. Do not forget to replace rear-window wipers as well.

- Do I need to clean my windshield before installing new wipers?

-

Windshield contamination is a common cause for poor wiper performance even if the wipers are still in good shape. Some kinds of contamination, such as tree sap, can destroy the wiping element in a short time. We recommend cleaning the windshield regularly with soap and water or a household glass cleaner. For tougher contamination, a non-abrasive household cleaner, such as Bon Ami, may be used.

- How difficult will it be for me to install my own blades?

-

Bosch Wiper Blades are designed with the do-it-yourself customer in mind. For most vehicle applications, the Bosch-exclusive DirectConnect™ installation system allows for quick and easy one-step installation without having to deal with adapters.

- What can I do to prevent snow and ice from clogging up my blades?

-

Winter blades (snow blades) are protected against snow and ice build-up through a rubber boot, covering brackets and joints. Even without the rubber sleeve, Bosch wiper blades offer better winter performance because the metal tension spring is enclosed in the rubber element rather than being exposed on its outside. The enclosed tension spring helps keep the wiper blade flexible and effective in wintry conditions.

- Do all wiper blades lift off at high speeds?

-

Bosch Wiper Blades feature a low-profile, aerodynamic design with vent holes in the center bracket. This design provides safety at high driving speeds.

- Why should I purchase Bosch Wiper Blades?

-

Bosch has been manufacturing electric windshield wiping systems for over 80 years. This knowledge of the entire wiping system helps Bosch understand what determines excellent wiper performance. Bosch supplies wiper systems and wiper blades to a large number of vehicle manufacturers. The expertise from original equipment manufacturing goes into each replacement wiper they make. Offered at various price levels, Bosch Wiper Blades are available for virtually every vehicle on the road.

- What is the function of a spark plug and why is it a vital engine component?

-

The function of the spark plug is to introduce the ignition energy into the combustion chamber and to initiate combustion of the compressed air-fuel mixture. It accomplishes this task by generating a spark between its electrodes, which then generates the required heat to ignite a smooth burn of the air/fuel mixture. The spark plug is an important factor in determining optimal performance and reliable functioning of an engine. It must permit reliable cold starting, it must guarantee that there is no misfiring during acceleration, and it must withstand the engine being operated for hours on end at maximum power. These requirements apply throughout the entire service life of the spark plug. For 100 years, Bosch Spark Plugs have been designed for optimal performance, reliable functioning, and to withstand extreme operating conditions. Today, the continuously developing spark plug is a key engine system component. It plays a major role in fuel economy, clean, efficient combustion, and the reliable operation of engines and catalytic converters.

- What are the different types of spark plugs?

-

There is a large variety of different spark plug designs with more than 1,400 variations. Design variants and special materials such as platinum, silver, or yttrium allow Bosch spark plugs to be used in a wide variety of applications today. In all, Bosch has developed more than 20,000 different types of spark plugs over the last 100 years.

- Why do we need to change spark plugs?

-

During operation, the spark plug is subjected to both wear and to fouling and should be replaced at regular intervals. In the course of its service life, the spark plug undergoes changes that increase the required ignition voltage. When the required voltage reaches a level that can no longer be compensated for by the voltage reserve, the result is misfiring. These changes can be caused by: Electrode wear Engine wear Abnormal operating conditions (pre-ignition, detonation, high oil consumption) Independent tests have shown that installing premium spark plugs such as Bosch’s Platinum+4 improves fuel mileage by as much as 4.8% over original equipment plugs. Platinum+4 uses race-tested technology including multiple electrode paths and more pure platinum to generate strong, consistent sparks.

- Are Bosch Spark Plugs pregapped at the factory?

-

Most Bosch Spark Plugs are factory pre-gapped for popular vehicle applications.

The gap measurements are indicated either on the box, or by the part number located on the spark plug shell.

- X suffix = .044"

- Y suffix = .060"

- Z suffix = .080"

Gaps should never by adjusted on Platinum+4 or Platinum+2. Bosch Platinum+4 and Platinum+2 have factory pre-set gaps, and should never be gapped by the installer.

Bosch Platinum and Super Spark Plugs also have factory-set gaps. For most plugs, the setting is shown on the plug package. These gaps are correct for the most popular applications of these plugs. There are applications, however, for which the gap setting has to be adjusted according to the vehicle manufacturer’s specifications. To avoid damage to a spark plug in the process of adjusting the gap, it is important to follow these guidelines:

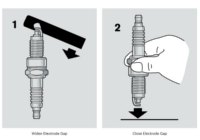

- To widen the electrode gap, use a tool that only pulls back the ground electrode, without applying pressure to the center electrode. The tool must not be wedged between the electrodes as that may cause damage to the insulator nose.

- To close the electrode gap, carefully tap the plug, electrode first, on a hard surface, as shown in the illustration.

- What is detonation?

-

Detonation or "knocking" is uncontrolled combustion with a very steep rise in pressure. It is caused by spontaneous ignition of the fuel mixture, which has not yet been reached by the ignition spark. As the high-pressure waves hit the walls of the combustion chamber, their impact produces a metallic knocking sound. Failure to recognize and deal with knocking will inevitably lead to serious engine damage.

- How does Bosch test engines to determine the heat range and what heat range should I use?

-

To ensure optimal performance in your car, Bosch has tested each vehicle model and the various engines available for that model listed in the Spark Plug catalog. Using a special spark plug with a thermocouple built in, Bosch engineers find the hottest cylinder in an engine and then test various spark plugs in that cylinder until the ideal plug is found. This ensures that you will always get the best performance possible.

- I want to use Bosch Spark Plugs, but have modified my engine by adding a performance system. Can I still use the plug listed in the catalog for my vehicle?

-

If you have modified your engine with a performance system such as a turbocharger, supercharger, or nitrous, the recommended spark plug may not be correct. You may need to use a plug with a colder heat range to compensate for the additional heat generated by the engine. Bosch recommends that in these situations, you consult a qualified engine builder for assistance in determining the appropriate heat range.

- How often do I need to change my plugs?

-

As a rule, Bosch recommends that you follow the replacement interval listed in your vehicle owners manual, however they highly recommend that you inspect (read) your spark plugs annually and replace as required, to insure optimum engine performance.

- Do Bosch Spark Plugs meet original equipment requirements?

-

Yes! Bosch Spark Plugs meet or exceed warranty requirements of all vehicle and engine manufacturers, and when properly installed in accordance with the recommended application, will not adversely affect the emission control system of any vehicle.

- What about vehicle manufacturer warranties?

-

Consumers are sometimes told by an automobile dealer’s service writer or mechanic that a brand of replacement spark plug cannot be used in the consumer’s vehicle during the warranty period. The claim is made that use of the brand will “void the warranty”, with the statement or implication that only the original equipment brand of spark plugs may be used. This, of course, tends to cast doubt on the quality of the replacement spark plug. That claim is not true. Under the Magnuson-Moss Warranty Act and general principles of the Federal Trade Commission Act, a manufacturer may not require the use of any brand of spark plug (or any other article) unless the manufacturer provides the item free of charge under the terms of the warranty.

So, if the consumer is told that only the original equipment spark plug will not void the warranty, they should request that the OE spark plug be provided free of charge. If they are charged for the spark plug, the manufacturer or dealer is in violation of the Magnuson-Moss Warranty Act.

- How does platinum improve a spark plug?

-

Perhaps the greatest innovation in spark plug design over the years is “pure platinum” technology, combined with multiple electrodes. As early as the 1960’s engineers recognized the value that platinum added to automotive plugs: it provides improved corrosion and erosion resistance and imparts a longer performance life than the standard copper core center electrode plug design. The use of platinum not only broadens the heat range beyond that achieved with a copper core center electrode design, but also provides extremely consistent performance, a reliable spark and a longer performance life.

- What are the advantages of surface air gap plugs such as Platinum+4 and Platinum+2?

-

To validate the improved performance of surface air gap plugs with a pure platinum core and multiple ground electrodes, extensive testing was conducted in the laboratory and in the field:

- The first test measured the energy transfer efficiency of the four-electrode platinum plug compared to conventional and other premium plugs with a single ground electrode. This certified laboratory test measured the additional pressure generated by the spark discharge in a pressure chamber. Higher pressure equals a higher energy transfer by the spark. The test showed that the four-electrode platinum plugs transferred more energy to the air/fuel mixture resulting in improved driveablility and lower emissions.

- As a spark plug wears via erosion and corrosion, the gap between the center electrode and ground electrode gets larger. The larger the gap, the more voltage is required to produce a spark, until the capability of the ignition system is exceeded and the plug misfires. It was found that the multiple ground electrode, pure platinum center electrode plug reduces gap erosion and increasing voltage requirements over time.

- Roush Industries, an independent test lab, measured the fuel consumption for the four-electrode platinum plug, as well as, that for original equipment and other premium single ground electrode plugs. Fuel savings up to 4.8% were found in the four electrodes, platinum core plugs. Tests were conducted in accordance with Federal Test Procedure 75FTP and HFE.

- Tests for carbon fouling were simulated in a cold cell by repeatedly cooling, starting and operating the engine without letting the spark plugs reach their self-cleaning temperature. This cycle does not let the spark plug reach its self-cleaning temperature and allows the formation of carbon deposits. The tests found that the four ground electrode spark plugs had up to 33% better cold restart reliability than conventional plugs.

- Does technology used in racing plugs find its way into Bosch Premium plugs?

-

YES! Racing, as it has for 100 years, provides a great developmental impetus and test bed for spark plug durability and performance, and what is learned at Indy or Darlington, or Le Mans helps improve the spark plugs installed in today’s cars or trucks. From the first Indy 500 won by Ray Harroun’s Marmon Wasp to the last 17 Indy 500 winners, and many in between, each have used Bosch spark plugs. Many premium passenger car spark plugs use multiple ground electrodes and precious metals, such as platinum, which are a direct result of their development and testing in long distance racing.

- What if I do not feel a difference after I have Bosch Premium Spark Plugs installed?

-

Bosch guarantees that you will feel improved performance in your vehicle when using a spark plug of the Bosch Platinum Series (Platinum+4, Platinum2, and Platinum). However, if you do not experience quicker starts, smoother acceleration, and improved fuel efficiency, you can return the plugs with a dated sales receipt and Bosch will refund the purchase price of the spark plugs.

Glossary:

Multi Ground - Plugs with multiple ground electrodes are called multi ground. These plugs also use surface gap spark patterns and the multiple ground electrodes increase service life.

Surface Gap - Surface gap technology is when the ground electrode is to the side of the center electrode. There can be no ground electrode (racing applications), multiple ground electrodes (PT+4 and PT2), or a single ground electrode. These spark plugs have improved efficiency and a higher probability of igniting a lean air/fuel mixture.

Resistor- Many spark plugs have a special conductive glass seal between the center electrode and the terminal stud. This seal acts as a resistor in the plug which reduces the transmission of pulses of energy to the ignition cables. These pulses can cause Radio Frequency Interference (RFI) with electrical components in the car. For some newer cars, resistor plugs are required for effective communication between the plugs and the electronic ignition.

Radio Frequency Interference (RFI) - When the spark plug creates a spark, a high frequency burst of energy is created. If this energy was to travel through the ignition wires, it could cause interference with other sensitive electronic devices, such as the radio or electronic control units. The resistor in the spark plug reduces this energy before it causes interference with other electrical components.

Fouling - Fouling occurs when a plug becomes contaminated with fuel, oil, or other contaminates that prevent the plug from generating a spark. Most plugs today are designed to reduce fouling and become self-cleaning when they reach 500 degrees Celsius. However, short trips, low speed driving, improper spark plug heat range (too cold), improper timing, or an oil leak in the combustion chamber can cause a spark plug to become fouled.

Bridging - Over time, contaminants can build on the surface of the spark plug if it does not reach self-cleaning temperature often. These buildups can grow between the electrodes until they are actually connected by a bridge of contaminants. This will often cause misfire.

Flashover- Occurs when the spark does not jump between the electrodes within the combustion chamber, but instead jumps between the metal shell and the terminal on top of the plug. This will always cause a misfire since the air/fuel mixture will not be ignited. Bosch spark plugs have a ribbed insulator to prevent flashover.

Quenching- The purpose of a spark plug is to introduce enough heat into the combustion chamber to initiate a smooth burn of the air/fuel mixture. Quenching occurs when that heat generated by the spark is reabsorbed back into the ground electrode, the center electrode, and the ceramic insulation. To reduce quenching and ensure an efficient transfer of heat, Bosch Platinum+4 and Platinum2 spark plugs use surface gap technologies.

- What does an oil filter do?

-

An oil filter is a crucial part of a vehicle‘s engine. Oil filters absorb potentially harmful particles that could damage the vehicle and allow filtered oil to move through various parts of the engine which is imperative to keep the engine cool. When oil passes through the oil filter, contaminants are trapped, preventing them from passing through through the vehicle’s engine.

- Why should I change my oil filter?

-

Regularly changing your car's engine oil and filter is one of the most important things you can do to keep your car running correctly. When a vehicle‘s oil filter becomes full of dirt and contaminants it will go into bypass mode – which means the filter media will stop absorbing potentially harmful particles and both the oil and the contaminants will flow through the engine. It is better to have dirty oil in the engine vs. no oil at all, however, when the oil filter is in bypass mode and allows dirty oil to head straight to the engine, it has the potential to cause permanent and costly damage.

- Aren’t all oil filters the same?

-

No. Not all competitors use the quality materials that Bosch prides itself on using. Lower quality materials may cause more frequent oil changes which can end up costing more money.

- How do you install an oil filter?

-

Always check your vehicle's owners manual before you install a new oil filter. But in general, locate the oil train plug and empty the dirty oil into a catch pan. Allow oil to drain completely and then replace the plug. Locate the oil filter and allow residual oil to drain around it. Unscrew and remove the oil filter from its position. Always check to ensure the old gasket came off with the old filter. Compare your old oil filter to your new one to ensure that you have the correct filter replacement. Apply a light coating of used oil to the new filter gasket and install the new filter on the engine by turning it clockwise. Use your hand to spin the filter all the way into the engine. If it is hard to spin it, the threads may not be lined up or you may have the wrong filter. When the oil filter has spun all the way on, use your hand to tighten another one-quarter to one-half turn. Don’t use a tool to tighten the filter or it may be very difficult to remove the next time. When you have finished doing this, turn your car on and let it run for about one minute to make sure there is no oil dripping from anywhere.

- How often should I change my oil filter?

-

Based on the filter and oil you‘re using, and the driving conditions, oil filter changes may be different for each individual. Bosch manufactures several lines of oil filters to last the recommended oil change interval that is recommended in your vehicle‘s owners manual. You should always consult your owners manual before changing the oil filter.

- What are the signs I need to change my oil filter?

-

There are several signs that will tell you it’s time to change your filter:

- The oil will look black and gritty

- You can‘t remember the last time you changed your oil

- The level of your oil is getting low

- Based on recommended change interval in owners manual

- If the change oil light in your car comes on

- Why should I purchase a Bosch DistancePlus Oil Filter?

-

Bosch DistancePlus Oil Filters are proven to hold up to 300%** more dirt, allowing the filter to perform longer. In addition, to its high capacity, DistancePlus is also a 99.9% efficiency* filter, and it works with any brand of synthetic or conventional motor oil. A DistancePlus Oil Filter also has 2Xs* greater burst resistance strength.

* Based on ISO 4548-12 at 40 microns on D3500

**Compared to conventional filters

- What is brake pad glazing?

-

Brake pad glazing is the crystallization of friction material resulting from the brake pad reaching temperatures above the specified heat range (overheating) or improper “bedding in” of the brake pads. Such crystallization can result in poor stopping performance, additional brake vibrations, or cracking in the brake pad material.

- Where are Bosch QuietCast™ Premium Brake Pads manufactured?

-

Bosch’s manufacturing occurs worldwide; however, Bosch QuietCast™ Premium Brake Pads are primarily manufactured using North American sourced steel and assembled in other parts of North America and the Asian-Pacific region.

- What is brake fade?

-

Brake noise occurs as a result of vibration.

- What is the best way to improve brake performance?

-

The best way to improve brake performance is to purchase high quality brake components such as Bosch QuietCastTM Premium Brake Pads and Bosch QuietCastTM Premium Disc Brake Rotors. Additionally, a thorough brake job that restores a vehicle’s brake system to its original operating condition can also improve a vehicle’s braking performance.

- How do I break in the pads?

-

Once new brake pads are installed, make 10-15 gradual stops from 20 mph to 0 mph. Next, make 10-15 slow down cycles from 35 mph to 20 mph. This gradually increases the operating temperature of the friction material seating the pad in the caliper and bracket. Additionally, this process also seats the friction material to the rotor’s surface.

- How do ceramic and semi-metallic brake pad formulations function differently?

-

Ceramic brake formulations insulate heat produced by the braking system within the immediate area where the braking occurs. Semi-metallic braking formulations disperse heat produced by the braking system throughout the vicinity of where the braking occurs rather than just within the braking system itself. The vehicle’s original equipment specifications should determine whether ceramic or semi-metallic brake pads best suit your vehicle’s needs.

- Do Bosch QuietCast ™ Premium Brake Pads include shims?

-

Bosch QuietCast™ Premium Brake Pads for most vehicle applications in North America are equipped with Bosch’s patented Molded Shim Technology (MST). Unlike most aftermarket brake shims, Bosch uses a rubber core shim surrounded by steel that is bonded to the backing plate via a thermoset adhesive. At the time of pressing, heat, adhesive, and pressure mold the multi-layer shim to the backing plate and friction material creating an integrally molded unit that won’t ever walk or slide on the backing plate. This unique design provides maximum stability resulting in quieter shim performance over the life of the pad.

- Do Bosch brake pads include hardware?

-

Yes, on select applications.

- Why is an integrally molded attachment process better than a riveted method of attachment for brake pads?

-

An integrally molded form of attachment is stronger than a riveted form of attachment because the friction material is fused to the backing plate creating one single component strengthening the integrity of the entire braking system.

- What should I use to clean the surface of the brake pads?

-

Generally, no additional substances should be applied to the braking surface of the brake pads.

- What causes my wheels to be constantly covered with brake dust?

-

Brake dust can occur due to a combination of rotor surface wear, brake pad wear, or the way the air vents through a vehicle’s wheel.

- How often should my brake system be inspected?

-

A vehicle’s braking system should be checked as stated by the vehicle’s factory maintenence schedule.

- What is the best way to improve brake performance?

-

The best way to improve brake performance is to purchase high quality brake components such as Bosch QuietCastTM Premium Brake Pads and Bosch QuietCastTM Premium Disc Brake Rotors. Additionally, a thourough brake job that restores a vehicle’s brake system to its original operating compacity can also improve a vehicle’s braking performance.

- Why should machined brake rotors be washed when installing new pads?

-

Machined rotors should be washed with a mild dishwashing detergent and hand brush prior to installing new brake pads. This process removes machining debris left on the surface of the rotor from the machining process. Failure to properly wash the machined rotors can result in damage to the friction material on the new pad and additional vibration and noise.

- What does an oxygen sensor do?

-

The oxygen sensor sends a signal to the engine computer based on the amount of oxygen in the exhaust gas. This signal is used by the engine ECU to fine-tune the mixture to the optimum level for maximum catalyst efficiency and longevity. A worn-out oxygen sensor can cause excessive gasoline consumption, elevated exhaust emissions, accelerated catalytic converter damage failures and cause engine performance problems such as surging and hesitating.

- Except for the connector assembly, aren't all oxygen sensors basically the same?

-

NO. There are five fundamentally different types of oxygen sensors: unheated thimble, heated thimble, planar, wide-band and titania. Within each sensor type, sensors vary in the design of the ceramic element, heater element and protection tube design, all of which affect sensor operation.

Unheated Thimble: This was the first oxygen sensor design and Bosch has been producing them since 1976. These sensors either have one wire or two (for purposes of grounding), since they do not require power for a heater element. They use a zirconia ceramic element to generate a voltage in a rich (insufficient oxygen) gas environment. They can take several minutes to reach operating temperatures of 625 degrees Fahrenheit after a cold start, however this varies with application as the location of the sensor determines the rate at which it heats.

Heated Thimble: These sensors were introduced by Bosch in 1982 and function in the same manner as the unheated thimble, however inside the thimble is a special heating element that brings the sensor up to operating temperature in about 30-60 seconds. The additional wires to power the heater- typically a total of 3-4 wires (dependent on grounding scenario) can identify these sensors.

Planar: This sensor was introduced by Bosch in 1997 and also uses the zirconia ceramic sensing technology, but placed in a more compact thin flat shape (hence the name) instead of a thimble or conical shape. This allows the sensor to be smaller and lighter. They also require less electrical power as the heater is integrated into the smaller sensing element. By model year 2004, planar oxygen sensors are expected to account for over 30% of all new oxygen sensor applications and by 2007 for over 50% of new oxygen sensors. These sensors also have only four wires.

Wideband: This is the newest design of oxygen sensor and it offers the increased accuracy needed to meet the latest emissions requirements. Unlike all the other types of oxygen sensors, the wide-band sensor can actually measure the air/fuel ratio from 11:1 (excess fuel condition) all the way to straight air (no fuel)! (The ideal air/fuel ratio is 14.7/1.) This improved measurement allows the engine control system to measure the actual air/fuel ratio and eliminates the switching between lean and rich associated with a traditional type of oxygen sensor. These sensors use a planar zirconia ceramic element, so that they heat up much faster than other types of sensors- reducing cold start emissions. These sensors can be identified with having five or more wires. In addition, these sensors are used with the newly developed gasoline direct injection engines. Direct injection engines can use stratified charges, which produce a very lean mixture in the combustion chamber, and these sensors must be used because of their ability to measure from very lean to very rich accurately.

Titania: These sensors use a different type of oxygen sensing technology and instead of generating a voltage signal that changes with the air/fuel ratio, the sensor’s resistance changes. These sensors are used on less than 0.5% of all oxygen sensor equipped vehicles.

- How do I know if my oxygen sensor may be damaged?

-

Unfortunately, the symptoms of a slow or even a dead sensor are not always obvious to the vehicle owner unless the vehicle fails an emissions test, a decline in fuel economy is noticed, or if driveability problems occur. Over time, exhaust contaminants accumulate on the sensing element reducing the sensor's ability to respond quickly to changes in air/fuel mixture and slowly the sensor becomes inoperable. Some symptoms of failed oxygen sensors are:

- Failed emissions test (high CO and/or HC typically)

- Damaged catalytic converter (caused by an over rich fuel mixture)

- Poor fuel mileage (caused by an over rich fuel mixture) Engine runs rough

- Sluggish performance

If the “check engine” light comes on while driving, check your oxygen sensor, and if necessary replace it with a new premium Bosch Oxygen Sensor.

- What will damage my oxygen sensor?

-

An oxygen sensor can fail prematurely if it becomes contaminated with phosphorus from excessive oil consumption, silicone from internal coolant leaks, using silicone sealant in the engine, and some over-the-counter fuel additives. Even a small amount of poorly refined gasoline can kill an oxygen sensor. Environmental factors such as road splash, salt, oil, and dirt can also cause a sensor to fail, as can thermal shock, mechanical stress, or mishandling. However as required by vehicle manufacturers, Bosch sensors are designed and tested with these extremes in mind.

- How can I test my oxygen sensor?

-

Unfortunately, the symptoms of a slow or even a dead sensor are not always obvious unless the vehicle fails an emissions test, a decline in fuel economy is noticed, or if driveability problems occur. Furthermore, while a dead sensor can be detected with a relatively inexpensive digital volt-ohmmeter, a slow sensor can only be diagnosed by a more expensive oscilloscope or scope meter.

- Where are oxygen sensors located and do they have different purposes?

-

Oxygen sensors have been standard equipment on almost all passenger cars and light trucks with gasoline engines since 1980-1981. Most vehicles built before the mid-90’s have one or two oxygen sensors (two were used on selected V6 and V8 engines starting in the late 1980s). Oxygen sensors are normally located in the exhaust system before the catalytic converter to measure exhaust emissions as they come from the engine combustion chambers. In 1996 with the federal mandated use of on-board-diagnostic systems (OBDII), vehicles also require additional oxygen sensors after the catalytic converter, to ensure that the converter is operating properly.

- I have a Bosch original equipment 4-wire sensor. What do the wire colors mean?

-

All Bosch 4-wire sensors have a black wire for the signal, a gray wire for ground and 2 white wires for the heater. Note: the wire colors and functions on non-Bosch sensors are not necessarily the same as on Bosch sensors.

- Does Bosch test all oxygen sensors manufactuerd to ensure their quality?

-

Yes! Bosch tests all oxygen sensors it manufactures by subjecting each of them to a 1,000 degree Celsius functional test and a leak test to ensure environmental and functional robustness. The 1,000 degree Celsius test darkens the outer protection tube, but ensures 100% functional sensor performance.

- What is a universal heated oxygen sensor?

-

Bosch has created an aftermarket universal heated oxygen sensor program. These sensors meet OEM operating requirements and have a patented connector system easing installation. This connector system has been proven to be watertight, protect against contamination, and withstand the effects of extreme temperatures and engine vibration. Currently Bosch offers 12 different 4 wire sensors and 2 different 3 wire sensors to provide the closest match to OEM sensor performance. See the Technical Info tab for a diagram of the connector system, featuring special high temperature Posi-Lock® connectors.

- Why should I change a damaged Oxygen Sensor?

-

According to a study conducted by Sierra Research Inc. in 1996, worn-out oxygen sensors are the “single greatest source of excessive emissions for fuel-injected vehicles” and the second most significant cause of high emissions in carburetor engines. The U.S. Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) have found that oxygen sensor replacement was required on 42%-58% of all vehicles that were subjected to an emissions check and found to be emitting high levels of hydrocarbons or carbon monoxide. Testing the oxygen sensors according to the vehicle manufacturer’s service procedures and replacing a sluggish or worn-out oxygen sensor can improve fuel economy from 10% to 15% (on pre-OBDII vehicles) and pay for itself in a year in fuel savings alone, while restoring your vehicle’s emissions to proper levels. And it can reduce the chance of an overly rich fuel mixture damaging the vehicle’s catalytic converter.

- Why do diesel engines require glow plugs and what function do they perform?

-

Unlike gasoline engines which use a spark plug to ignite an air/fuel mixture, diesel engines rely on the heat of highly-compressed air to ignite a precise amount of fuel to initiate combustion. Heating the air to a minimum starting temperature of 850°C is critical for diesel engine start-up.

In low temperatures, factors such as cold intake air and cold cylinder walls hinder the attainment of the necessary starting temperature. In these situations, glow plugs function as an additional heat source to bring the intake air up to the temperature necessary to initiate the combustion cycle.

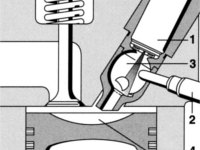

There are two basic types of diesel combustion cycles:

Direct-injection engine

1. Nozzle holder with injection nozzle

2. Sheathed-element glow plug

3. Combustion chamber

Pre-chamber engine

1. Nozzle holder with injection nozzle

2. Sheathed-element glow plug

3. Pre-chamber

4. Combustion chamber

- What is Bosch Duraterm® technology and how is it different from other glow plug technologies?

-

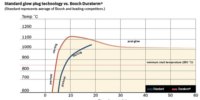

Bosch’s revolutionary Duraterm® glow plug technology utilizes a self-regulating control system that reduces glow wait time by more than 50%. The patented dual-control regulating and heating coil effectively directs current draw, enabling the glow plug to reach higher temperatures more quickly for faster engine start-up. The regulating coil keeps the heating element within the 1000° – 1100°C optimal temperature range, preventing engine damage due to over voltage/overheating.

For vehicles with a post-glow† control system, this advanced technology offers a post-glow heating phase. During the post-glow phase, glow plugs continue to operate for up to three minutes after the engine has started, improving overall engine performance and reducing smoke emissions and combustion noise.

Bosch Duraterm® technology is available for the majority of diesel car and light truck applications. Other applications employ standard glow plug technology per OE specifications.

- What causes glow plug failure and what are the results?

-

Excessive voltage is the leading cause of glow plug failure.

Glow plugs are designed to operate within a temperature range of 850° – 1100°C. During operation, the glow plug controller switches current to the glow plug for a specific period of time to allow for proper heating. However, when the controller fails, current could be applied for a longer than specified time causing the temperature of the glow plug to exceed the 1100°C upper limit. Under these conditions, the glow plug overheats causing the casing to swell, split or burst which allows air to enter the coil area causing immediate failure.Other causes of glow plug failure include:

- Improper testing procedure (applying 12 volts directly to a glow plug designed to operate on 6 volts)

- Incorrect engine timing

- Improper fuel injector spray pattern

- Continual cycling of the glow plugs

Damage like this will most likely result in engine failure. Removing a glow plug with a distended or broken tip may require engine head removal — a time-consuming and costly repair.

- What conditions indicate that it's time to replace the glow plugs?

-

The following signs most likely indicate that it’s time to change a vehicle’s glow plugs. If any of these conditions exist, be sure to check the vehicle’s glow plugs and if necessary, replace them with a new set of Bosch Glow Plugs.

- Vehicle won’t start

- Vehicle starts only after excessive cranking (Excessive cranking can cause the engine oil to be diluted with fuel, which could adversely effect the life of the engine)

- Vehicle idles roughly after initial start-up

- Excessive exhaust emissions after initial start-up

- Can only the worn or failed glow plug(s) be replaced, or should all glow plugs be replaced at the same time?

-

If one glow plug fails, chances are the others won’t be far behind. To minimize vehicle down-time and save on labor costs, Bosch recommends changing all glow plugs at the same time.

- Bosch is not the OE glow plug on this vehicle. Is Bosch comparable to the OE brand?

-

You can replace OE glow plugs with Bosch with complete confidence. Bosch is currently the OE glow plug on most European diesel vehicle applications. And for Domestic and Japanese vehicle applications, Bosch Glow Plugs are designed to meet and/or exceed the OE glow plug specifications.

- Will Bosch Premium Starters and Alternators provide the same performance as my original unit?

-

Yes! Bosch units are specifically engineered and built to deliver the same or better starting and charging power as the original equipment units they replace. Every component used to build Bosch Starters and Alternators is subject to the same rigorous Bosch Original Equipment quality standards. For example:

Features and Benefits

- Digitally tested rotor - Ensures up to 20% increased performance in maintaining optimal battery charge

- Superior voltage regulator circuit design -Maintains optimal voltages during all conditions to maximize the charging of the battery

- Can I be assured that the unit will last, especially in extreme weather?

-

Yes! Bosch Premium Starters and Alternators are manufactured especially for extremes of heat, cold, and high demand. Each unit is built to last using the highest quality materials and the most technologically advanced processes, including:

Features and Benefits

- Longer lasting bearings are constructed using the latest advances - Provides up to a 30% increased life over conventional bearings in precision grinding, polishing, and lubrication technologies

- Rigid welded construction for critical electrical connections - Ensures durability and reliability even in the hottest conditions versus soldered construction

- New insulation - Prevents damage due to temperature extremes, vibration, and chemical corrosion

- All new long-life self-lubed brushes and corrosion-resistant brush springs Increased durability under the toughest conditions

- How can I tell if I need a new starter?

-

If the engine cranks slowly or not at all, check the starting system. The starter could have failed, or excessive resistance in the wires and their connections can prevent the proper voltage from reaching the starter. Check for loose or dirty cable connections or for battery cables with wires that are too small in diameter. If everything else checks, measure the starter draw and amperage, if incorrect, replace the starter.

- How can I be assured my Alternator or Starter will fit when installed?

-

Every Bosch Premium Alternator and Vehicle Starter is application specific. In other words, it is a “one-for-one” match with the original equipment (OE) unit it is replacing.

- When should I replace my spark plug wires?

-

Any time a wire exhibits physical damage either to the wire or the boots, such as a cut, grooves or marks from chafing or scorch marks from burning, the wire should be replaced as preventative maintenance.

Additionally, some wires fail from the inside, due to a breakdown of their insulation materials. Wires should always be inspected and tested whenever a rough or erratic idle is present, poor acceleration is noticed, a decrease in fuel mileage is experienced or a vehicle fails an emissions test due to high hydrocarbon emissions or cylinder misfire fault code.

Wires should be replaced if their resistance exceeds the OEM specification for their specific application. Wires should always be replaced as a set due to the unpredictablility of the internal condition of each individual wire.

- What problems can happen if wires do not fit right?

-

Improperly designed wire sets can cause dangerous problems including interference with the throttle cable linkage, causing the gas pedal to stay open, or resting on the exhaust manifold, which would cause the wire to burn. In addition, if wire sets are not installed correctly problems can occur. When installing wire sets, make sure the connection between the spark plug and the cap is secure to avoid ignition problems.

Bosch duplicates the outside diameter of the original equipment wire for safe and secure fit in factory retainers and looms. Bosch closely follows the length of the original equipment for safe routing. Bosch always uses snug fitting original equipment style boots and connectors to ensure proper fit, function, and appearance while providing extreme durability and long life. All Bosch boots and connectors meet or exceed the high temperature requirements of the original equipment set.

- What are the benefits of using a Bosch MAG core wire set?

-

MAG core wire sets emply a sprial wound, magnetic firing core design. The Bosch MAG core is upgraded to premium by replacing standard metallic wire with a tightly wound low resistance stainless steel wire.

The benefits of the Bosch MAG core includes a hotter, more powerful and longer* spark resulting in optimum engine performance while reducing the chance for misfire and eliminating radio frequency static. There is no better core available.

That's why Original Equipment Manufacturers continue to switch from conventional core construction to MAG core Bosch wire sets for all domestic and Asian cars, trucks, and SUVs are constructed using Bosch premium MAG core technology.

*Laboratory testing has shown 16% longer spark duration over standard suppression construction. - How long do Bosch Spark Plug Wires last?

-

Because Bosch use only premium components, all Bosch Spark Plug Wire Sets are covered by a limited lifetime warranty. A detailed copy of this warranty is included inside every wire set box.

- What are some common problems that prevent spark plug wires from working properly?

-

Spark plug wires are designed to carry the electrical voltage from the ignition system to the spark plug. They are designed to have very low resistance so the maximum amount of the energy is transferred. This transfer of energy can be interrupted by several factors:

- Improper fit – please see questions 2

- Spark plug problems – If combustion gases leak past the spark plug, the spark plug wires can become unconnected from the spark plug terminal due to the increased pressure. Or, the opposite effect could happen and the gases can cause the spark plug and the wire terminal to corrode and fuse together

- Moisture – If moisture becomes trapped in the spark plug hole or between the plug and the wire, it can cause arcing. This will cause permanent damage to the spark plug wires and possibly the spark plug as well

- Excessive heat from exhaust headers – Routing spark plug wires in areas with excessive heat can destroy the silicone insulation. To prevent this, all Bosch spark plug wire sets are designed specifically for each application to ensure wires are out of harm's way

- Loose terminals – Spark plug wires need to be removed carefully. When removing the wire, do not pull on the wire, but instead grasp the plug boot firmly and gently remove it. Make sure the engine is cold. This will prevent the connectors from becoming loose

- What is EMI and do I need to worry about it?

-

Not with Bosch Premium Wire Sets. Electromagnetic interference (EMI), also called radio frequency interference (RFI) is caused whenever a current flows through a wire. This current creates a magnetic field that can disrupt other sensitive electronic components such as the engines electronic control unit or radio. For Japanese and domestic applications, Bosch wire sets have a RFI absorbent shielding material to eliminate interference. In European applications, a solid copper core wire is used with OEM-style resistor connectors that absorb unwanted EMI.